Organic waste gas treatment method

A technology for organic waste gas and treatment methods, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve problems affecting environmental quality, exhaust gas not up to standard, and affecting the service life of chimneys, etc., to prolong the desorption time and prevent The effect of cross gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

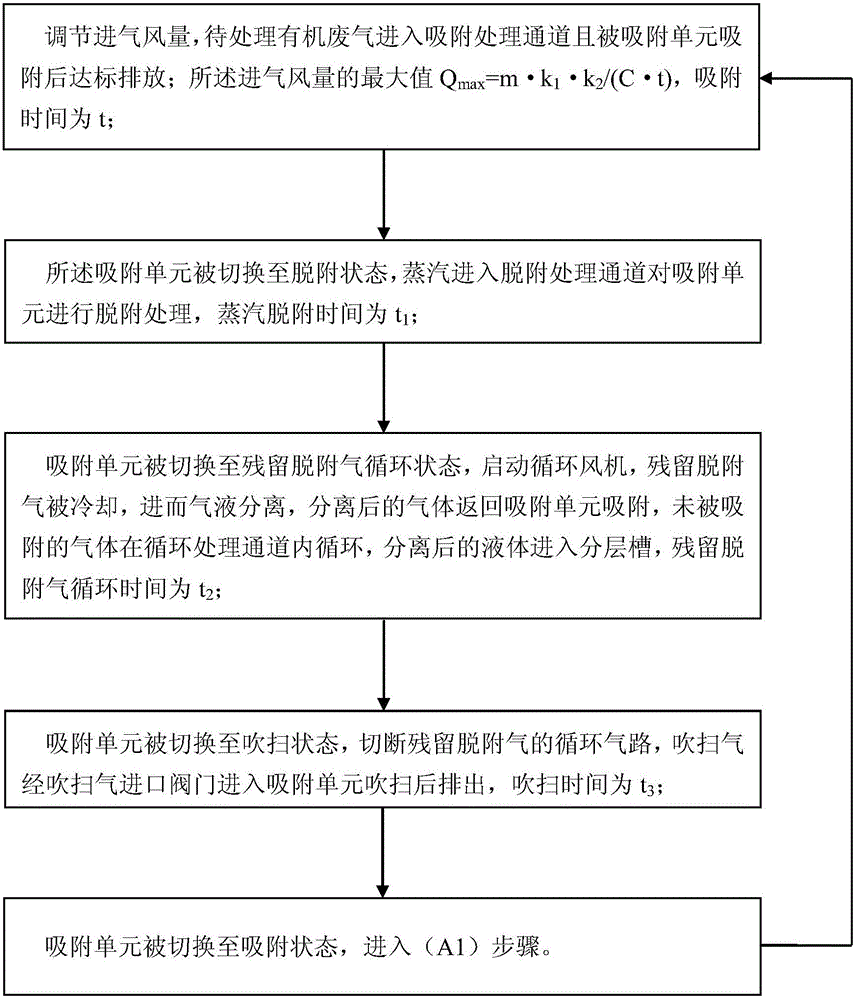

[0032] figure 1 A flow chart of the organic waste gas treatment method of this embodiment is schematically given, as figure 1 As shown, the organic waste gas treatment method includes the following steps:

[0033] (A1) Adjust the intake air volume, the organic waste gas to be treated enters the adsorption treatment channel and is discharged up to the standard after being adsorbed by the adsorption unit; the maximum value of the intake air volume Q max =m·k 1 k 2 / (C t), where m is the mass of effective adsorbent, k 1 is the dynamic adsorption capacity, k 2 To design the surplus coefficient, C is the concentration of organic matter in the organic waste gas to be treated, and t is the adsorption time;

[0034] (A2) The adsorption unit is switched to the desorption state, and the steam enters the desorption treatment channel to perform desorption treatment on the adsorption unit, and the steam desorption time is t 1 ;

[0035] (A3) The adsorption unit is switched to the re...

Embodiment 2

[0053] An application example of treating toluene tail gas according to the organic waste gas treatment method in Example 1. In this application example, the cooler is a surface cooler, and the pipeline between the surface cooler, the gas-liquid separator and the layered tank is provided with a liquid seal structure of ≥500mm; the later purge gas is air, and when the air enters the adsorption Filtered by an air filter before purging; the first inlet valve, the first outlet valve, the second inlet valve, the second outlet valve, the third inlet valve, the third outlet valve and the purge gas inlet valve are all pneumatic valves or The electric automatic valve is switched through the PLC control module. The PLC control module controls the switching by setting the adsorption time of the adsorber in different states. Specifically, the adsorption time of the adsorber is 30 minutes. While the adsorber is adsorbing, another When an adsorber is in the state of steam desorption, circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com