Sectioned inverted mounting method of stirring device of decomposing tank

A technology of a stirring device and an installation method, which is applied to a mixer with a rotating stirring device, a hoisting device, and accessories of a mixer, etc., can solve the problems of difficult installation of stirring fan blades, high construction risk factor, insufficient tank position, etc. The effect of avoiding allowable errors, reducing the number of reverse shipments, and reducing the risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

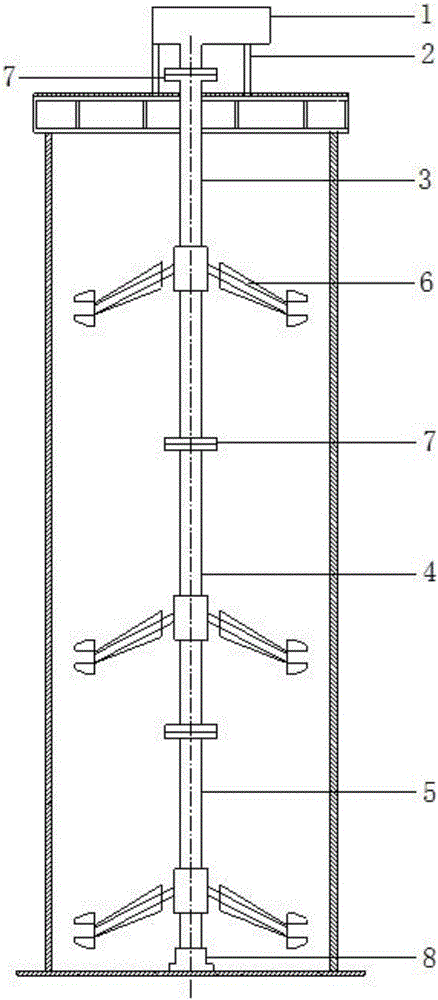

[0025] The stirring device is mainly composed of a motor and a reducer 1, a frame 2, a stirring shaft (mostly divided into three sections, which are divided into the first stirring shaft 3, the second stirring shaft 4 and the third stirring shaft 5 from top to bottom), stirring fan blades 6. It is composed of the bottom bearing frame and other parts, with a total weight of about 20 tons.

[0026] The whole stirring device is mainly suspended by the reducer 1 installed on the top of the tank, and the bottom bearing frame does not bear the axial load, but only limits the radial swing of the stirring shaft.

[0027] as attached figure 1 As shown, a segmented upside-down installation method of a decomposition tank stirring device includes the following steps: first, two hoists are installed on both sides of the installation hole of the reducer 1 on the top of the tank, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com