Adsorbent for petrochemical wastewater treatment and preparation method thereof

A waste water treatment, petrochemical technology, applied in the direction of water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of complex regeneration, difficulty in large-scale use, and expensive activated carbon, so as to improve the adsorption performance , Improve stability and strength, and enrich the effect of surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

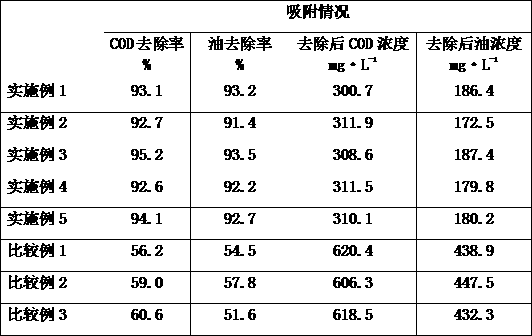

Examples

Embodiment 1

[0023] A preparation method of an adsorbent for petrochemical wastewater treatment, comprising the steps of:

[0024] (1) Preparation of modified composite powder: 15 parts of dedecyltrimethylphosphorus bromide modified attapulgite and 20 parts of tetraethylenepentamine modified rectorite were dispersed in 100 parts of toluene, and heated at room temperature Under ultrasonic vibration for 1h, then add 10 parts of quaternary ammonium salt tetrameric surfactant and 6 parts of polyacrylamide as modifier to carry out modification reaction, the modification reaction is carried out in water with polytetrafluoroethylene lining It is carried out in a thermal reaction kettle, the hydrothermal reaction temperature is 80°C, and the reaction time is 6 hours. After the reaction is completed, centrifuge, wash, and dry to obtain the modified composite powder;

[0025] (2) Preparation of composite cross-linked adsorbent: Add the modified composite powder obtained in step (1) to 10 parts of ch...

Embodiment 2

[0028] A preparation method of an adsorbent for petrochemical wastewater treatment, comprising the steps of:

[0029] (1) Preparation of modified composite powder: take 30 parts of dedecyltrimethylphosphorous chloride modified attapulgite and 40 parts of triethylenetetramine modified rectorite and disperse them in 180 parts of N,N-dimethyl In base formamide, and ultrasonic vibration at room temperature for 2h, then add 15 parts of quaternary ammonium salt tetrameric surfactant and 12 parts of polyacrylamide as modifiers for modification reaction, the modification reaction is carried out with Carry out in a polytetrafluoroethylene-lined hydrothermal reaction kettle, the hydrothermal reaction temperature is 120°C, and the reaction time is 10h. After the reaction is completed, centrifuge, wash, and dry to obtain the modified composite powder;

[0030] (2) Preparation of composite cross-linked adsorbent: Add the modified composite powder obtained in step (1) to 15 parts of chloroa...

Embodiment 3

[0033] A preparation method of an adsorbent for petrochemical wastewater treatment, comprising the steps of:

[0034] (1) Preparation of modified composite powder: 20 parts of cetyltriphenylphosphine chloride modified attapulgite and 30 parts of EDTA modified rectorite were dispersed in 150 parts of tetrahydrofuran, and Ultrasonic vibration at room temperature for 1.5h, and then add 12 parts of quaternary ammonium salt tetrameric surfactant and 8 parts of polyacrylamide as modifiers for modification reaction, the modification reaction is carried out in a polytetrafluoroethylene It is carried out in a lined hydrothermal reaction kettle, the hydrothermal reaction temperature is 100°C, and the reaction time is 8h. After the reaction is completed, centrifuge, wash, and dry to obtain the modified composite powder;

[0035] (2) Preparation of composite cross-linked adsorbent: Add the modified composite powder obtained in step (1) to 13 parts of chloroacetic acid, 12 parts of glutara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com