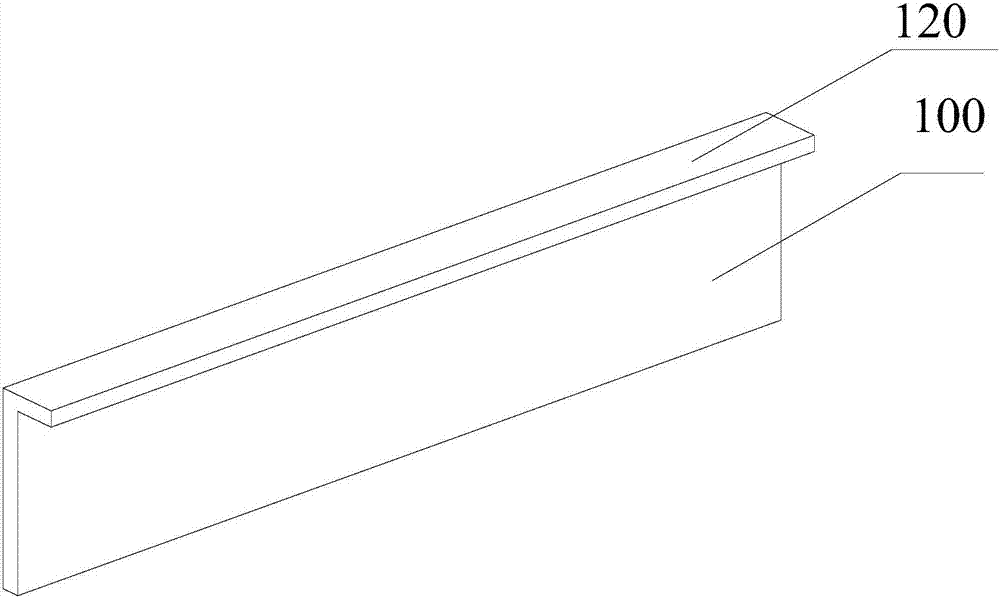

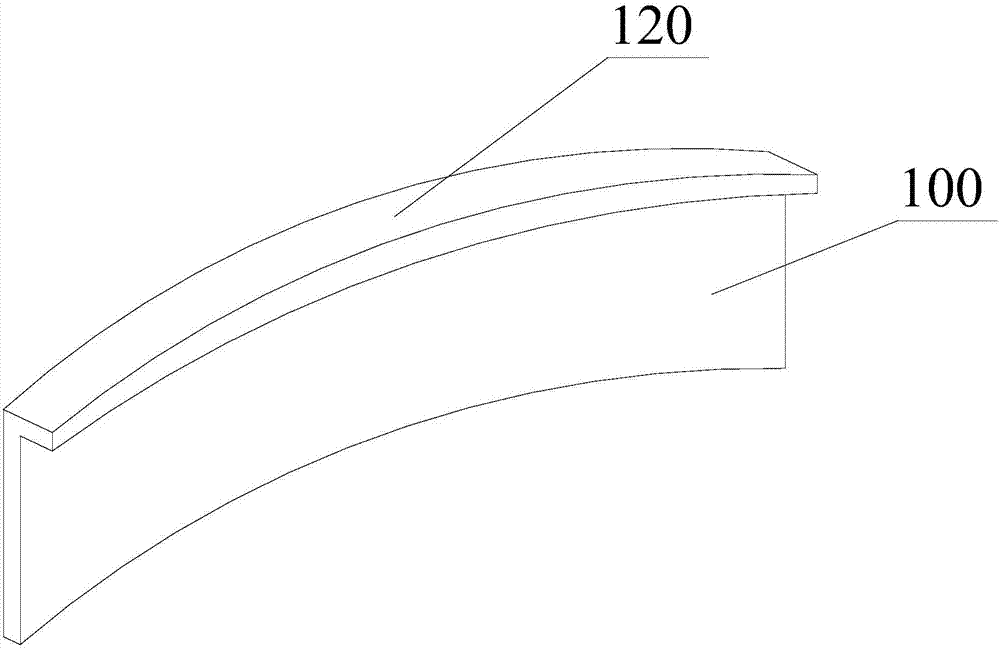

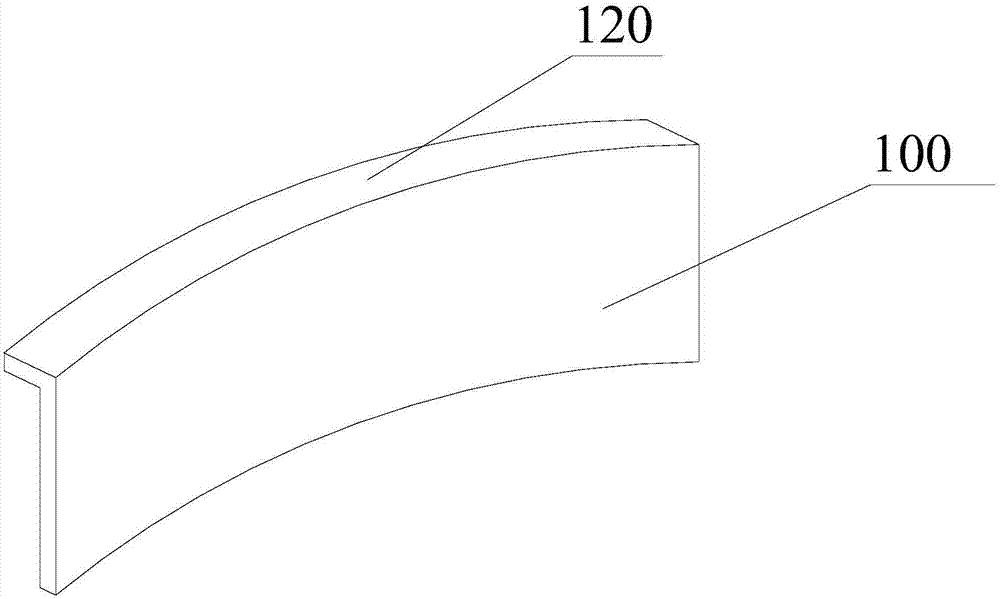

Bending device for circular arc coaming plate of radiator air guide cover

The technology of a bending device and an air guide cover is applied in the field of radiator air guide cover production, which can solve the problems of low production efficiency, unsightly appearance of the wind cover, and difficulty in guaranteeing the circular arc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] refer to Figure 4 , the present invention proposes a radiator wind guide cover circular arc coaming bending device, including a workbench 1, an auxiliary bending mechanism, a first bending mechanism, a second bending mechanism, a third bending mechanism and, wherein,

[0021] Auxiliary bending mechanism comprises auxiliary bending wheel 22 and first supporting shaft 21, and first supporting shaft 21 is vertically arranged on the workbench 1, and auxiliary bending wheel 22 is installed on the first supporting shaft 21, and auxiliary bending wheel 22 The outer periphery is provided with the first arc-shaped groove 23, the second arc-shaped groove 24 and the third arc-shaped groove sunken to its center and the first arc-shaped groove 23, the second arc-shaped groove 24, and the third arc-shaped groove have different radius of curvature.

[0022] The first bending mechanism comprises a first bending wheel 31, a second support shaft 32 and a first clamping device for clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com