Containment steel lining piece high-altitude welding tooling

A technology of containment steel and tooling equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that it is difficult to ensure the assembly position and accuracy requirements, and achieve the reduction of position adjustment time, accurate coordination and reliable Adjust and reduce the effect of work intensity and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific implementation the present invention will be described in further detail:

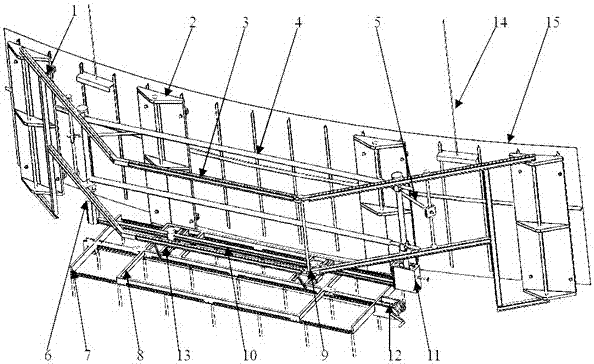

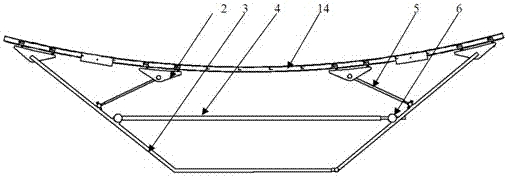

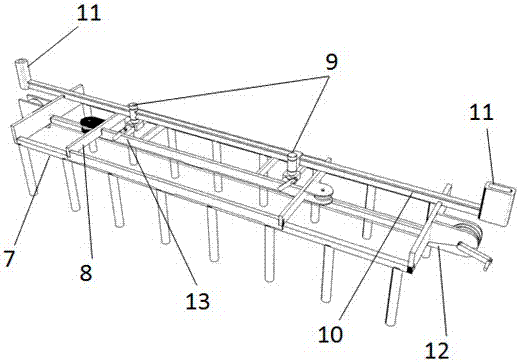

[0023] The structure of the high-altitude welding rapid tooling instrument for containment steel lining slices of the present invention is as follows figure 1 , consists of two parts: Slice Quick Fixture (see figure 2 ) and mobile platforms for high-altitude positioning (see image 3 ). After the two are assembled, the overall structure of the high-altitude welding rapid tooling for the containment steel lining is formed.

[0024] The structure of the split quick fixture is as follows figure 1 As shown, it includes a mounting frame and a quick chuck 1 arranged on the mounting frame. The mounting frame includes a main body bracket 1 , a primary movable pull rod 4 , a secondary movable pull rod 5 and a positioning rod 6 . The first-level movable tie rod 4 and the second-level movable tie rod are all length-adjustable rods, and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com