Machining process for marine propeller shaft with length of 22 metres and hollow middle

A processing technology and stern shaft technology, which is applied in the field of marine stern shaft processing technology, can solve the problems of difficult drilling deviation, cutting deviation, and reduced rigidity, so as to reduce the processing scrap rate, ensure the degree of external elements, and prevent holes The effect of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0028] The 22-meter-long middle hollow marine stern shaft processing technology in the present invention is realized through the following steps:

[0029] 1. Rough turning, the steps are as follows:

[0030] First, take a stern shaft to be processed, fix the stern shaft on a lathe for rough turning, and leave a margin of 25mm for each dimension of the outer element of the stern shaft.

[0031] Second, the drilling process, the steps are as follows:

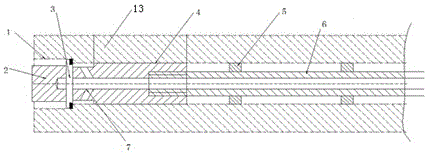

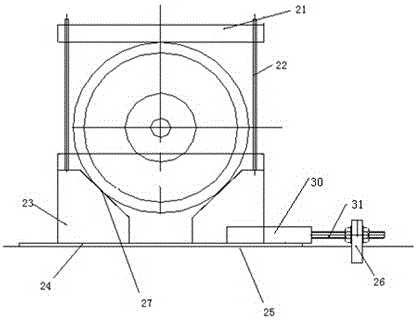

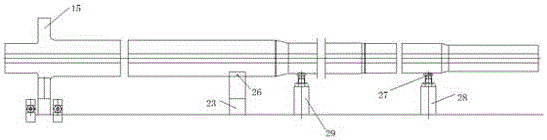

[0032] The first step, the stern shaft is fixed: at first, the stern shaft 13 to be processed is fixed on the boring machine, such as figure 1 As shown, the boring machine includes a boring machine pull bar 6, and a guide bar 4 is installed at the front end of the boring machine pull bar 6, by setting the guide bar 4, it can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com