Installation control method of glass lifter

A glass lifter and control method technology, applied in manufacturing tools, metal processing, metal processing equipment and other directions, can solve the problems of low installation and positioning accuracy, damage, low efficiency, etc., to improve installation efficiency and quality, convenient and fast operation , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

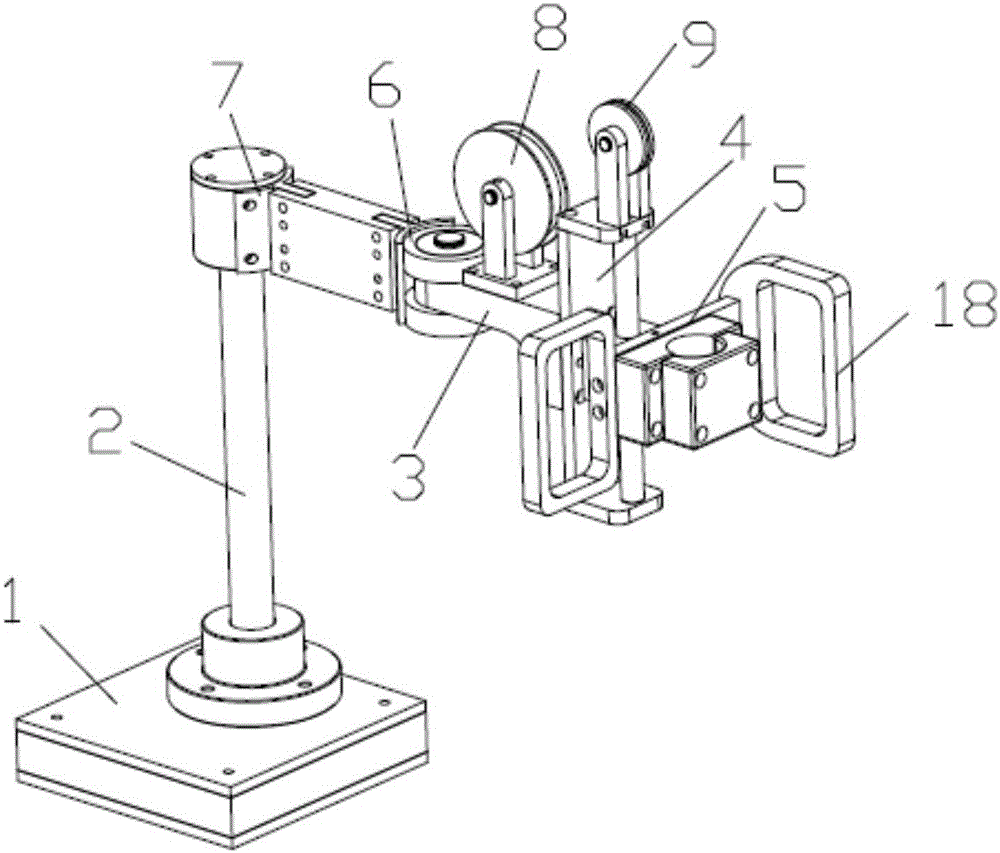

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0024] The installation control method of the glass regulator of the present invention, the control method comprises the following steps:

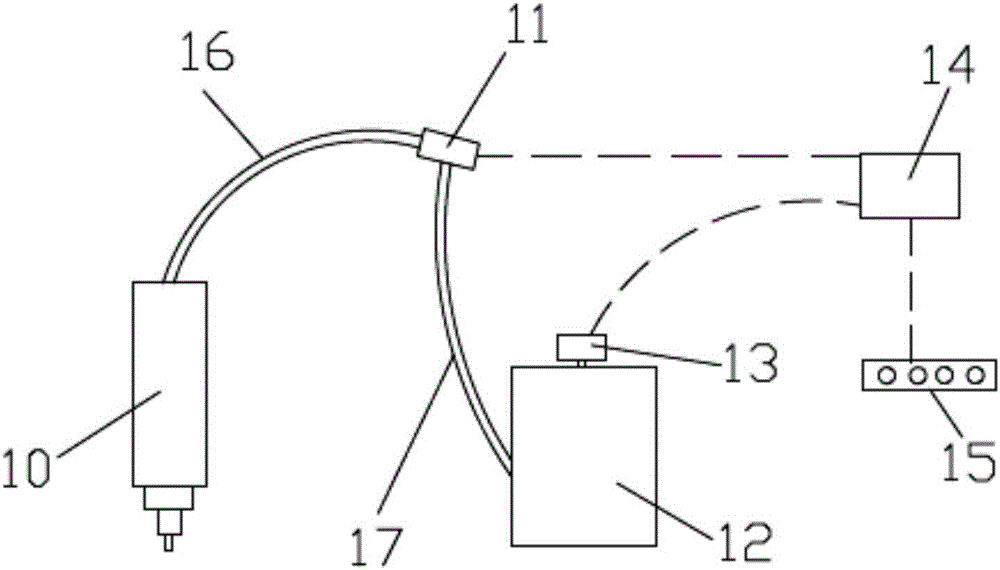

[0025] 1) Position the glass regulator to be assembled on the mounting part positioning device, and install the screw machine (10) on the screw rack;

[0026] 2) Start the main control power supply of the electric controller installed with screws;

[0027] 3) Adjust the air pressure to a suitable size by controlling the air source;

[0028] 4) Hold the operating handle 18, place the screw machine at the position above the screw to be driven by adjusting the horizontal direction, and align the screw downward to perform the screw driving operation;

[0029] 5) Complete the screwing operation of each screw position on the glass regulator in sequence.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com