Clamping fixture for multiple thin parts

A part clamping and clamping technology, applied in the field of machinery, can solve the problems of accumulated thickness error of multiple thin parts, affecting the machining accuracy of parts, and different thicknesses before and after, so as to achieve less time, eliminate workpiece warping and bending, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

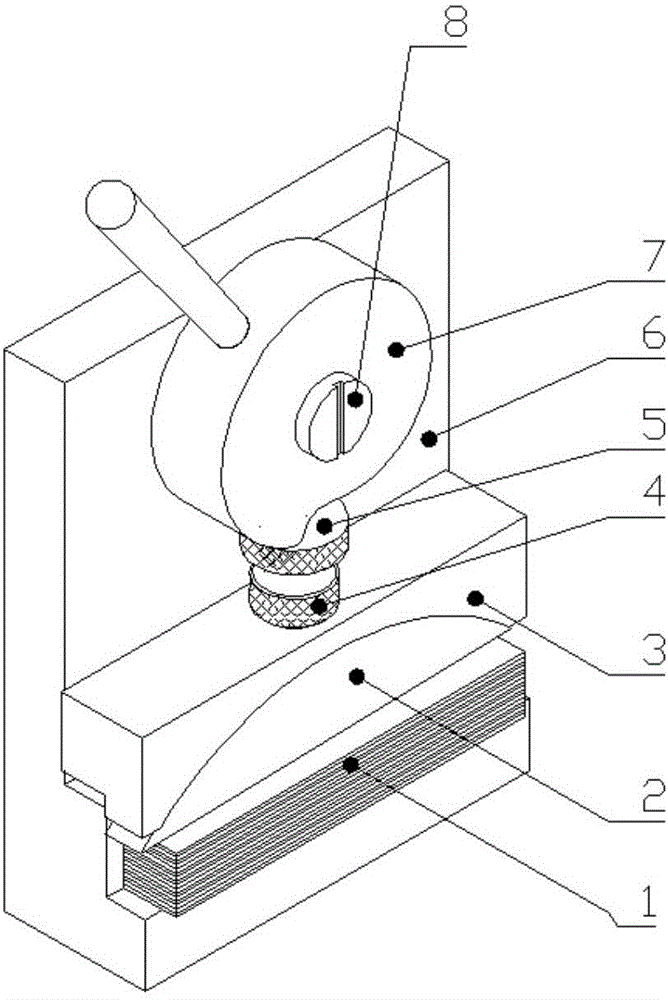

[0017] as attached 1 As shown, the present invention is a multi-piece thin parts clamping fixture, including a base with fixed jaws 6 , set on the base 6 movable jaws that move upward and move toward the fixed jaws 3 , drive movable jaw 3 Moving drive mechanism, fixed jaws and movable jaws 3 A clamping part is formed between the movable jaws 3 There is a semi-circular groove on the side facing the clamping part, and a swinging body is arranged in the semi-circular groove, when multiple thin parts 1 When there is a front and rear thickness error in the cumulative thickness, the semicircular platen 2 in the movable jaw 3 The swing of the semi-circular groove can still ensure the effective clamping of the workpiece.

[0018] In this embodiment, the oscillating body is set as a semicircular platen 2 。

[0019] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com