Novel polishing device for building

A new type of technology for construction, applied in grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, grinders, etc. Achieve the effect of improving performance and scope of application, convenient and fast operation, and protecting personal health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

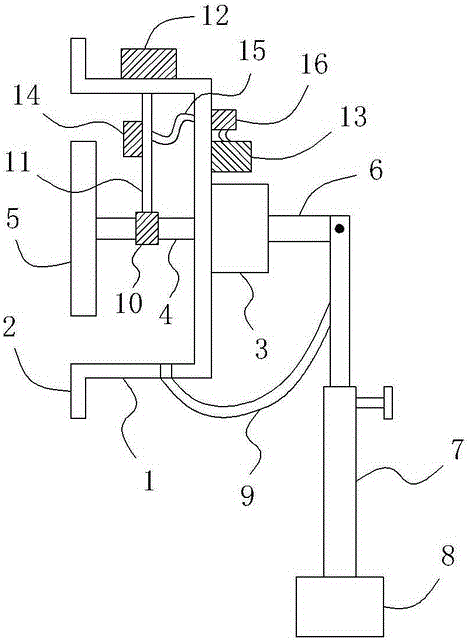

[0013] Such as figure 1 As shown, a new type of building grinding device includes a dust cover 1 with an opening at the left end, and an annular limit disc 2 is fixedly connected to the left end of the dust cover 1, and the left side plane of the annular limit disc 2 is evenly distributed. There are bristles, a motor 3 is provided on the right side of the dust cover 1, and a rotating shaft 4 is connected to the output shaft end of the motor 3, and the rotating shaft 4 extends leftward along the horizontal direction and extends to the inside of the dust cover 1. The left end of the grinding disc 5 is also provided with a grinding disc 5, and the left side plane of the grinding disc 5 is aligned with the left side plane of the annular limit disc 2, and a plurality of grinding disc holes are evenly opened on the grinding disc 5 (not shown in the figure) ); the right end of the motor 3 is also connected with a fixed rod 6, the right end of the fixed rod 6 is hinged with a telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com