Pump coiling device of water ring vacuum pump

A technology of water ring vacuum pump and disc pump, which is applied to wrench, wrench, hand-held tools, etc., can solve the problems of disc pump water ring vacuum pump and the inability to use simple wrench, etc., achieve good holding effect and increase radial force , Increase the effect of holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

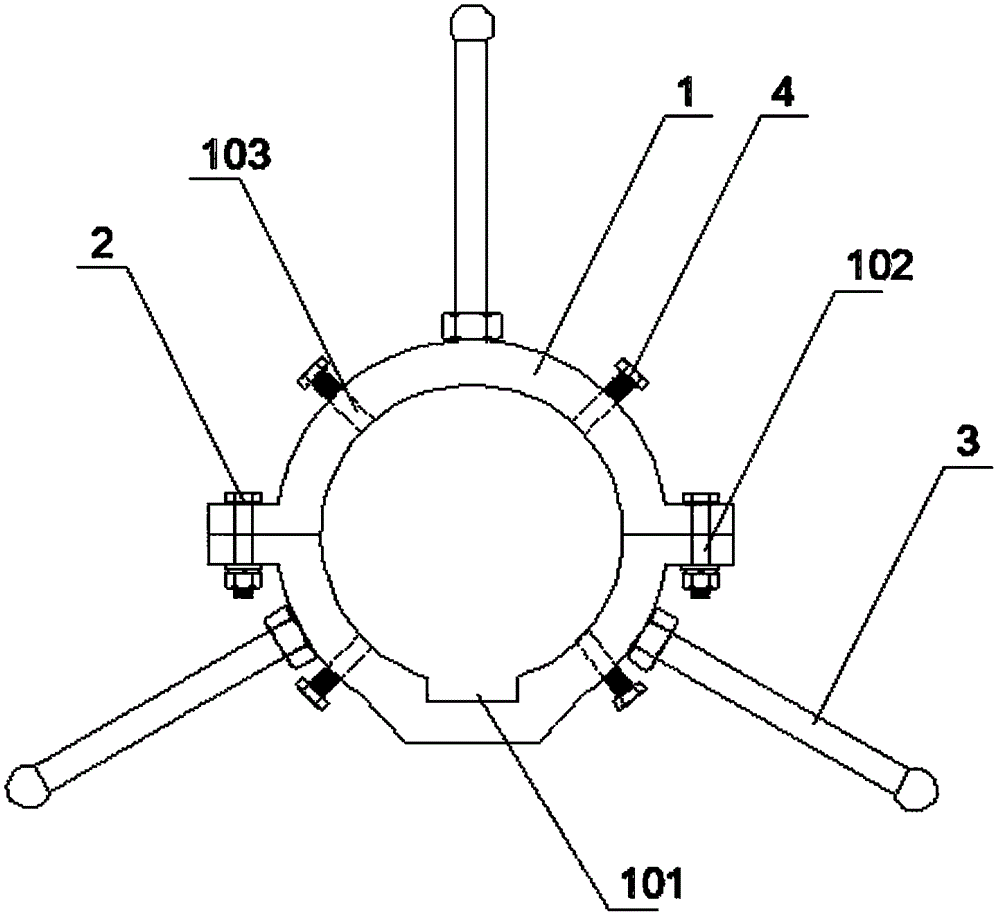

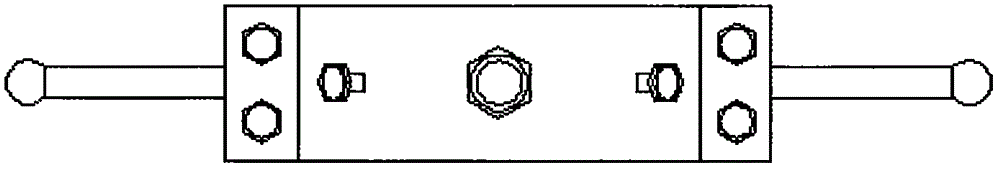

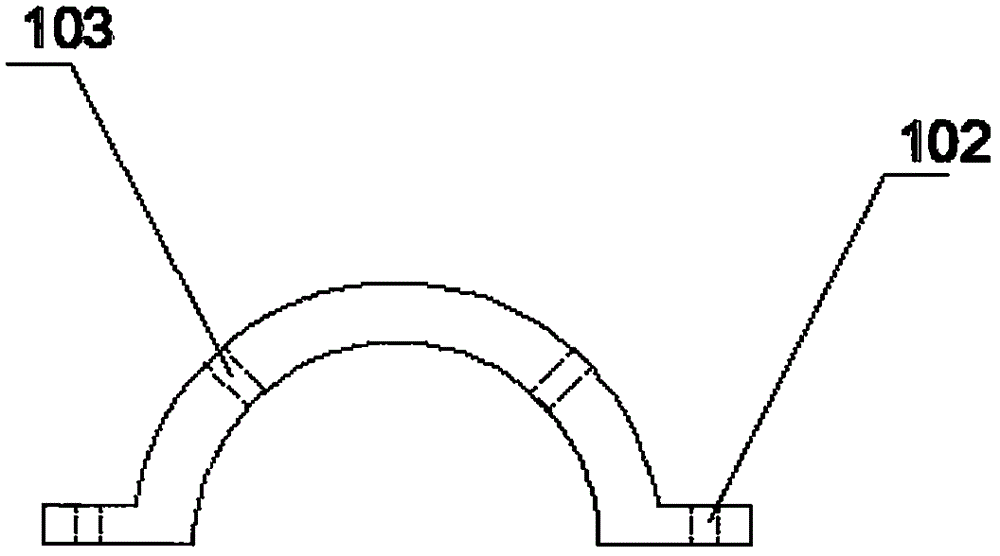

[0033] The disc pump device of the water ring vacuum pump includes a hoop 1, a hoop fastening mechanism and a wrench 3; the hoop 1 is composed of a front hoop and a rear hoop, and the front hoop and the rear hoop pass through the hoop The hoop fastening mechanism is connected to form a ring, which hoops the water ring vacuum pump; the inner side of the hoop 1 is formed with a slot 101, which is used to cooperate with the protrusion on the bearing of the water ring vacuum pump, so that the hoop 1 will not Sliding relative to the water ring vacuum pump; the wrench 3 is fixedly connected with the hoop 1 .

[0034] In this embodiment, the hoop fastening mechanism includes two hoop bolts 2, which cooperate with the hoop bolts 2, and two hoop bolt holes 102 are formed on the left and right ends of the hoop 1 , by passing the hoop bolt 2 through the hoop bolt hole 102, and then fixing it with a nut or forming a thread in the hoop bolt hole 102, so that the hoop 1 and the water ring ...

Embodiment 2

[0039] Compared with Embodiment 1, this embodiment mainly has the following two points of difference:

[0040] (1) The hoop fastening mechanism includes a hoop hook mechanism and a hoop bolt 2, and the hoop hook mechanism and the hoop bolt 2 are distributed at the left and right ends of the hoop 1; The hoop hook mechanism includes an outer hoop hook 104 formed on the front hoop and an inner hoop hook 105 formed on the rear hoop; matched with the hoop bolt 2, The right end of the hoop 1 is formed with a hoop bolt hole 102; the outer hook 104 of the hoop is matched with the inner hook 105 of the hoop, and at the same time, the hoop bolt 2 is passed through the hoop bolt. The holes 102 are fixed so that the hoop 1 is relatively horizontally fixed to the water ring vacuum pump.

[0041] (2) The front end of the wrench 3 is threaded to match the wrench 3, and the hoop 1 is also formed with a wrench fastening bolt hole 106, and the wrench fastening bolt hole 106 is formed with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com