Mobile phone vacuum lamination system with rotary feeder

A technology of rotary feeding and mobile phone, which is applied in the direction of packaging machine, packaging, transportation and packaging, etc. It can solve the problems of easy bubble film sticking operation efficiency, etc., and achieve the effect of high film sticking operation efficiency, small space and improved film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

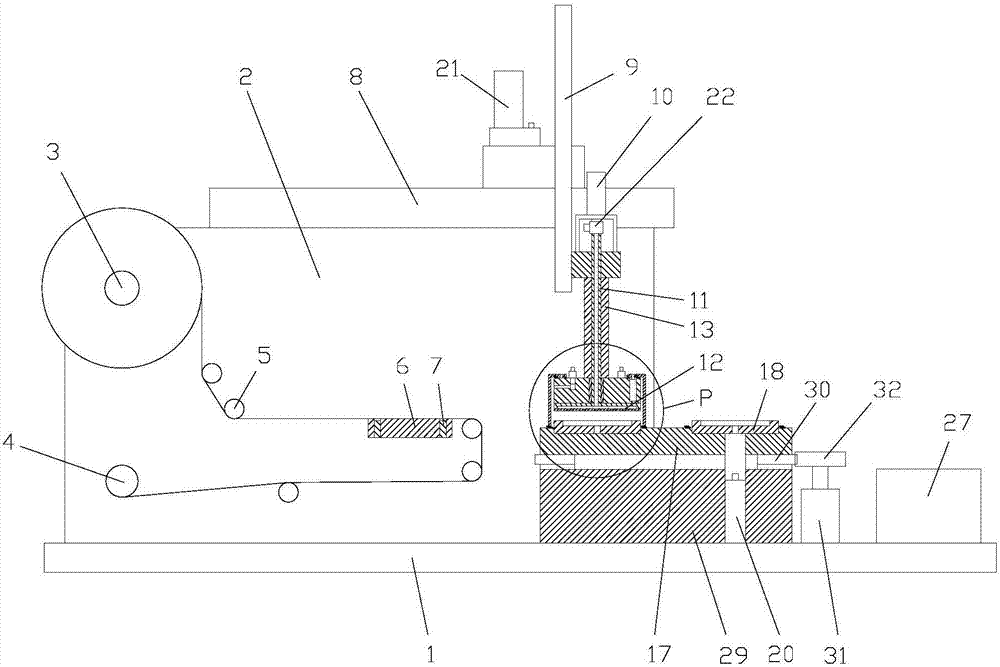

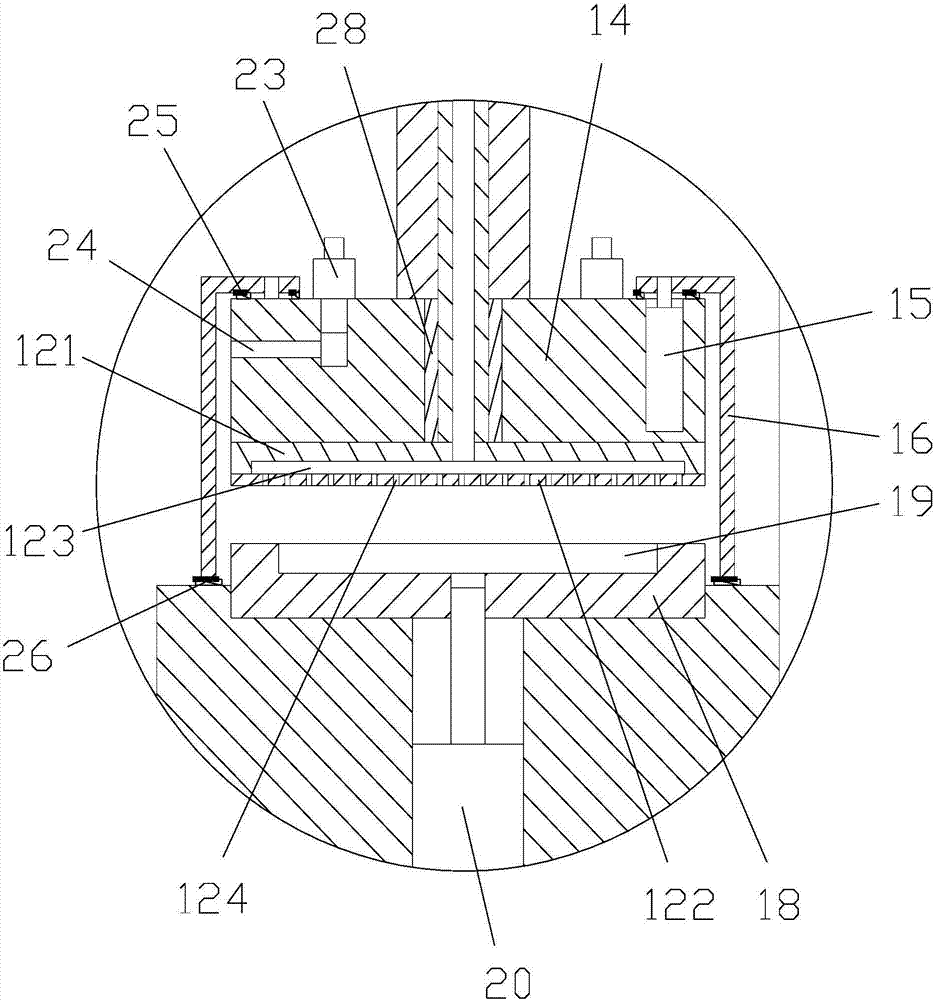

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] As shown in the figure, the mobile phone vacuum film sticking system with a rotary feeding device in this embodiment includes a bottom plate 1 and a vertical plate 2 perpendicular to the bottom plate, and the vertical plate is provided with an unwinding shaft 3, a winding shaft 4, and several guide shafts 5. The guide shafts include two guide shafts that enable the horizontal movement of the film feeding belt, and also include a horizontal plate 6 arranged at the lower part of the horizontally moving film feeding belt to support the film feeding belt. The horizontal plate is provided with a detection Send the sensor 7 of the position of the mobile phone film on the film belt, and the sensor can adopt a laser sensor or an ultrasonic sensor;

[0024] The top of the vertical plate is provided with a horizontally arranged first linear motor 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com