Garbage can lifting tool

A technology of trash can and spreader, applied in the direction of garbage receptacle, transportation and packaging, can solve the problems of poor safety, low degree of automation, low work efficiency, etc., and achieve the effect of good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

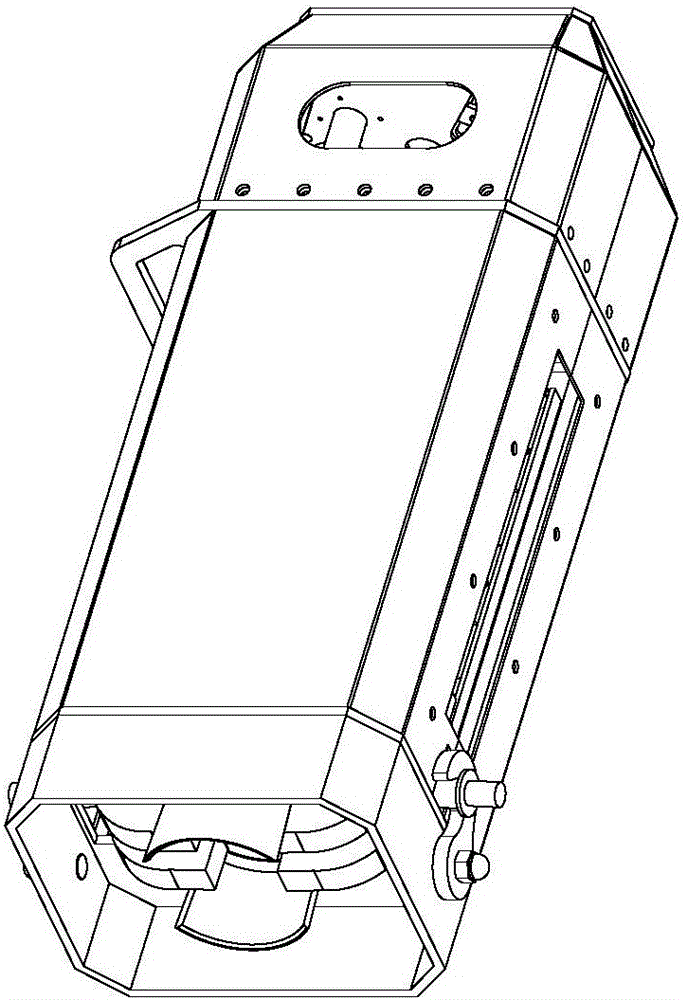

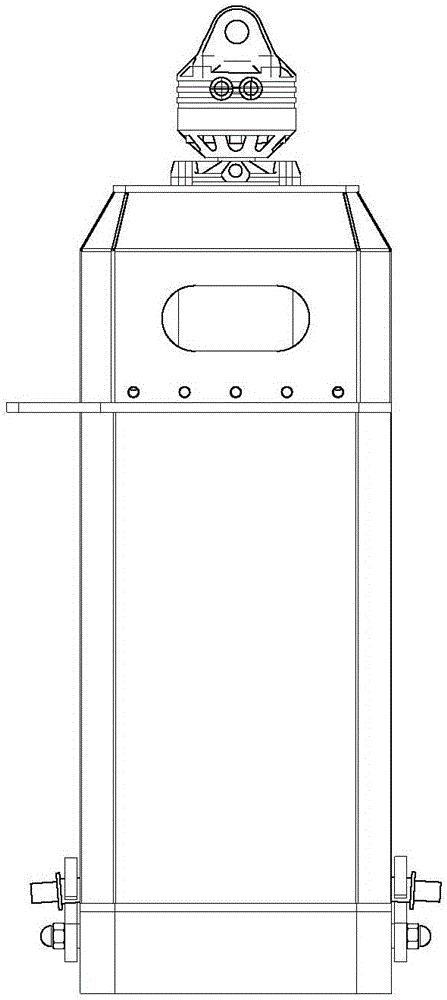

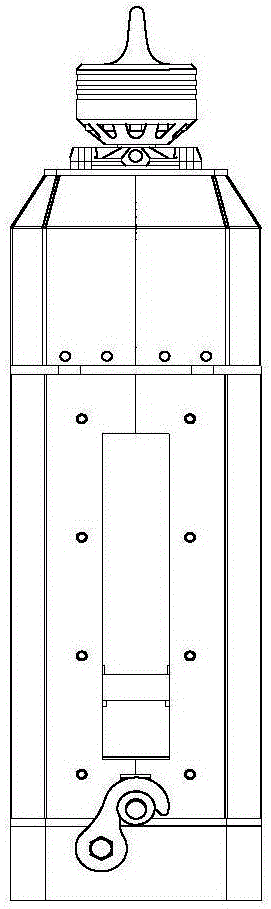

[0054] refer to Figure 1 to Figure 22, a garbage can spreader, a bottom cover opening and closing mechanism is provided on the buried garbage can, and the bottom cover opening and closing mechanism includes an inner boom, an outer boom, a beam, a column and a lifting chain, and the outer The boom is fixed on the trash can, the lower end of the outer boom passes through the middle of the beam, the inner boom is nested inside the outer boom and forms a pair of moving up and down, and the column is located on the One end of the beam is fixed on the trash can, the middle part of the beam and one end of the beam are respectively equipped with pulleys, the bottom of the inner boom is connected with the upper end of the lifting rope; the lower end of the lifting rope is passed around in turn The pulley in the middle of the beam and the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com