Conveyor support

A conveyor and support plate technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of inability to achieve complete contact between the conveyor unit and the beam, and the single function of the conveyor bracket, achieving rich functions, simple process, easy climbing The effect of slope conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

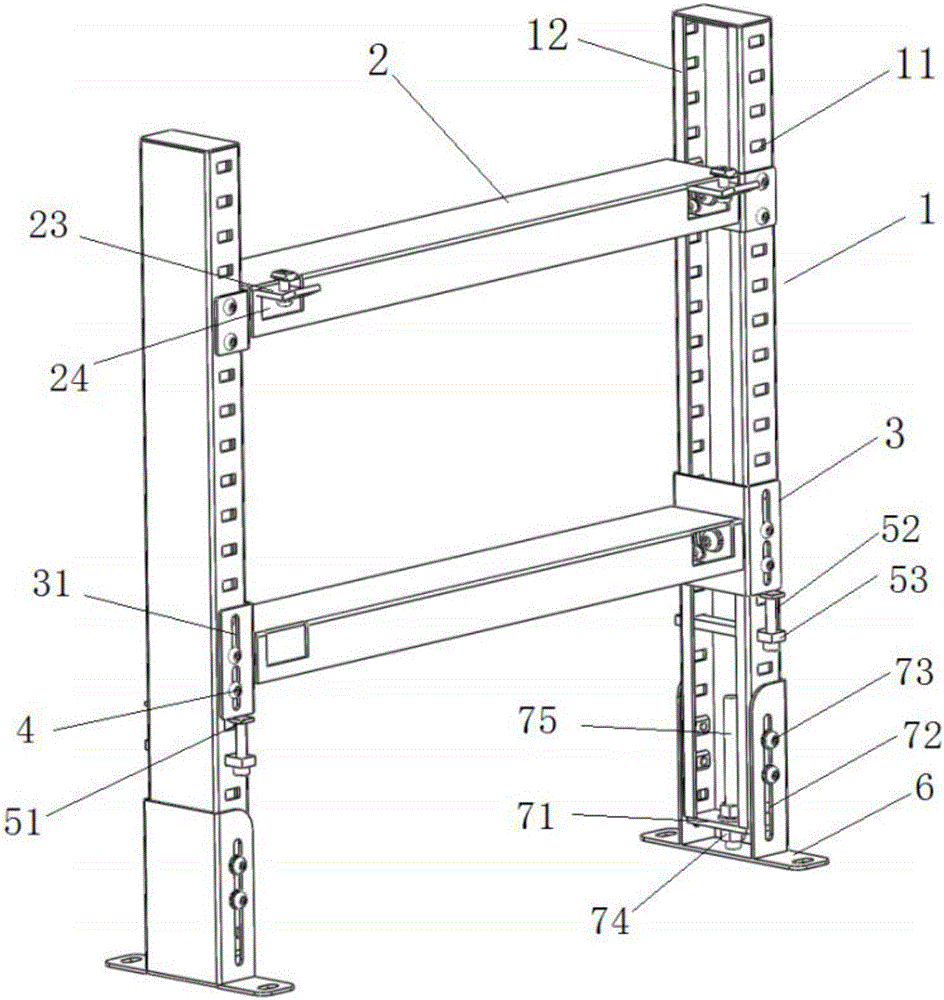

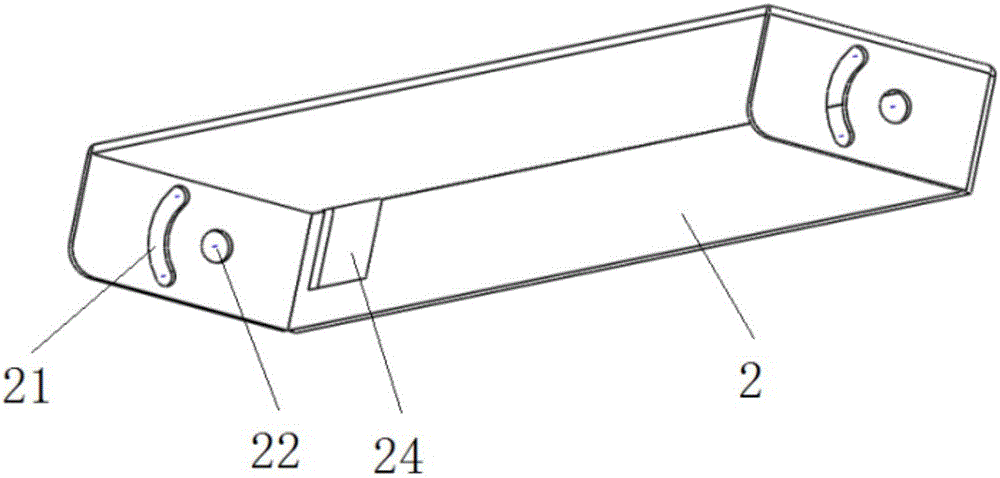

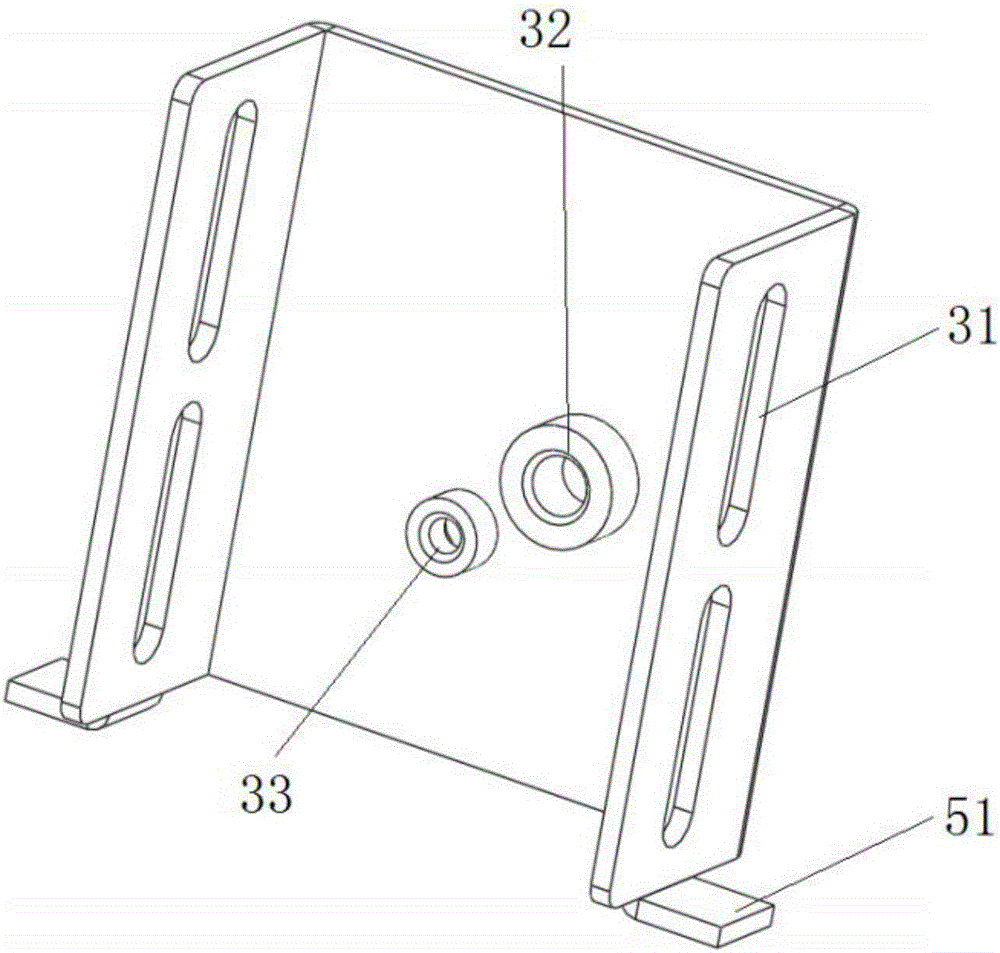

[0022] refer to figure 1 As shown in Figure 3, a conveyor bracket of the present invention is used to support and fix the conveyor, and it includes: a column 1, a connector 2 and a crossbeam 3, at least one beam 3 is arranged between two columns 1, and the crossbeam 3 is connected with the column 1 through the connecting piece 2, wherein,

[0023] The column 1 is provided with a plurality of symmetrical first fixing holes 11 on both sides; the two sides of the column 1 are designed to be bent, and the ends of the two sides are respectively provided with folded edges 12, so that the two sides form a space respectively. Cavities to accommodate square nuts;

[0024] The crossbeam 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com