Pneumatic conveyor

A technology of pneumatic conveying and air compressor, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc. It can solve the problems of lack of air temperature control, etc., and achieve the effect of simple and practical structure, stable pressure and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

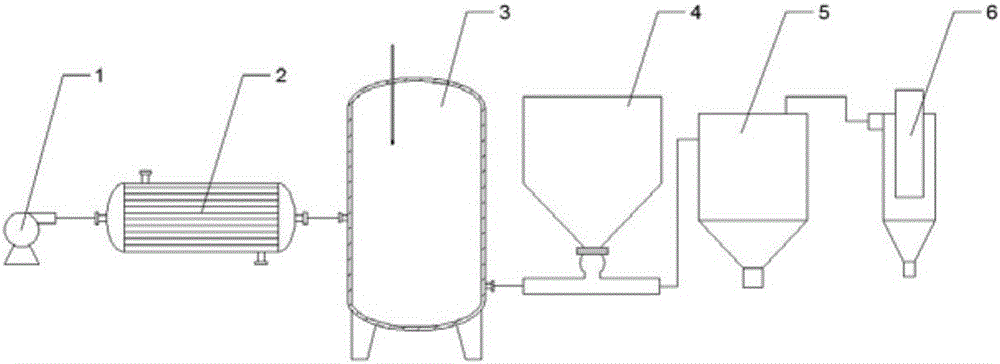

[0020] like figure 1 , figure 2 , image 3 A pneumatic conveyor shown includes an air compressor (1), a heat exchanger (2), a storage tank (3), a feeder (4), a material separator (5), and a dust collector (6); After the air compressor (1) compresses the air, it presses the compressed air into the heat exchanger (2). After the heat exchanger (2) heats up or cools down the compressed air, the compressed air enters the feeder (4) to bring the material into the material separation The material separator (5) and the material separator (5) separate the material from the waste gas, and the waste gas is discharged into the dust collector (6) for dust removal.

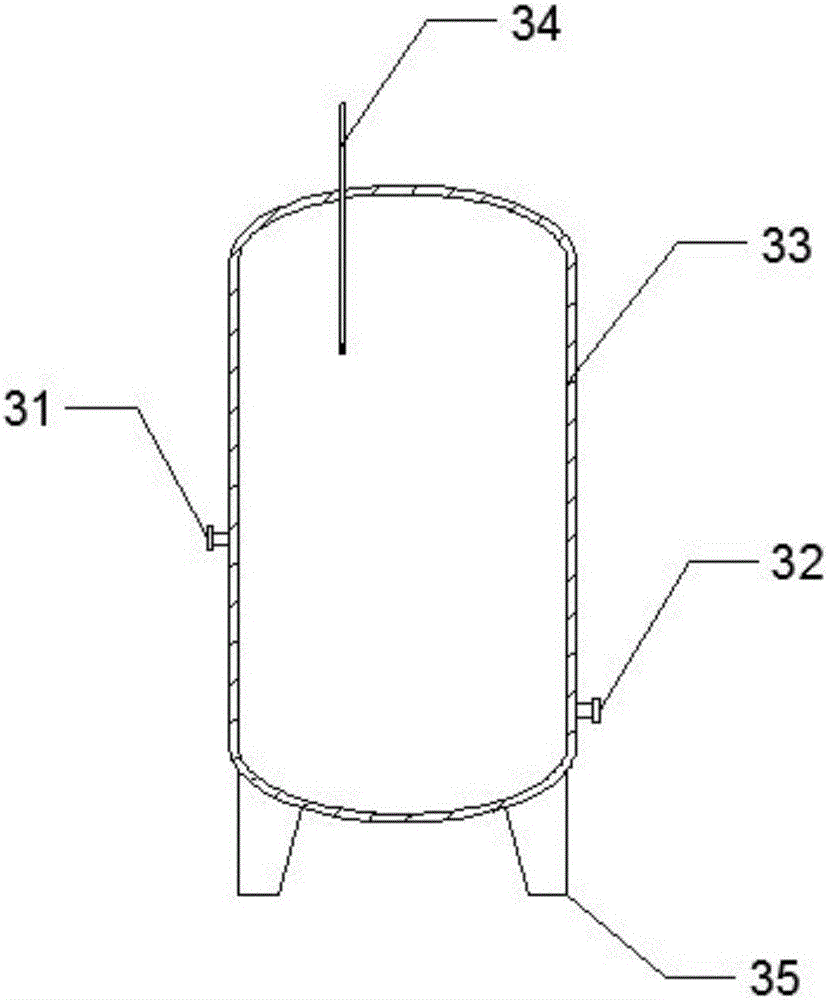

[0021] The storage tank (3) includes a tank body (33), legs (35), air inlet (31), air outlet (32) and a thermometer (34); Material.

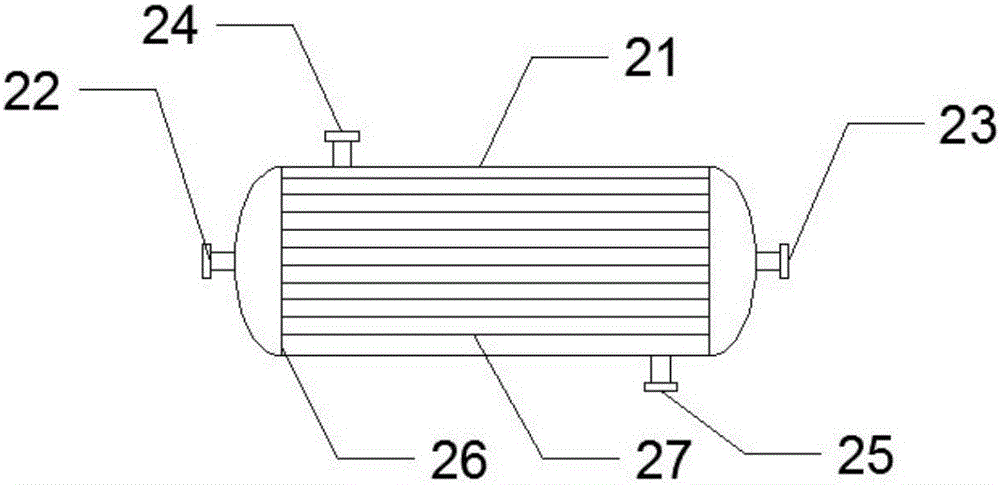

[0022] The heat exchanger (2) is a shell-and-tube hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com