Sealing structure for air extract opening of vacuum glass

A technology of sealing structure and vacuum glass, which is applied in the field of sealing structure of vacuum glass exhaust port, can solve the problems affecting the overall appearance of vacuum glass, achieve the effect of firm welding seal, reduce damage, and improve the initial vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

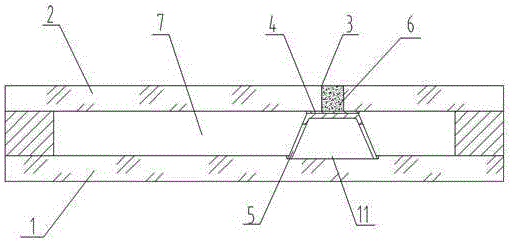

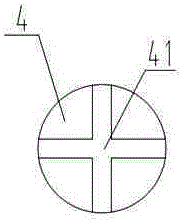

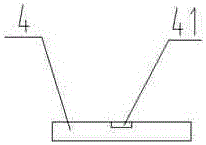

[0028] Such as figure 1 , figure 2 , image 3 In the sealing structure of the suction port of the vacuum glass shown, the upper glass 2 has a suction port 3, the lower glass 1 is sealed with the upper glass 2, and a cavity is formed between the upper glass 2 and the lower glass 1 The interlayer 7 is provided with a metallized layer around the suction port 3 on the inner side of the upper glass 2, an elastic support 5 is arranged in the cavity 7, and a metal sealing piece 4 is arranged on the top of the elastic support 5, and the metal sealing piece 4 The material is copper or copper alloy, and its surface is pre-coated with a certain thickness of tin, tin alloy, indium or indium alloy layer. The metal sealing sheet 4 is tightly attached to the air suction port 3 by the elastic support member 5, and an exhaust groove 41 is arranged on the end face of the metal sealing sheet 4 facing the air suction port 3, and the depth of the exhaust groove 41 is tin, tin alloy 1 / 3 to 1 / 2 ...

Embodiment 2

[0036] Such as figure 1 , Figure 4 The structure shown is basically the same as that of Embodiment 1, the difference is that the exhaust groove 41 is long, and the number of the exhaust groove 41 can be one long groove, or two parallel long grooves as in this embodiment , or more long slots side by side.

[0037] Certainly, the exhaust groove 41 may also be in other shapes such as a "rice" shape (not shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com