A kind of wear-resisting agent for shoes and preparation method thereof

A wear-resistant agent and technology for shoes, which is applied in the field of organic polymer compounds, can solve the problems of unstable wear resistance, poor bonding performance, and poor dispersion, and achieve durable and stable wear resistance, strong bonding performance, and high Dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

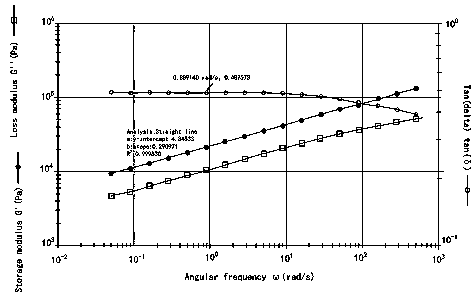

Image

Examples

Embodiment 1

[0037] In the present embodiment 1, a kind of wear-resisting agent for shoes is made up of following components by weight:

[0038] Polyolefin Elastomer 8003 45 parts

[0039] Silicone oil KS-1214 50 parts

[0040] TAIC-A 0.2 parts

[0041] BIPB 96 0.2 copies

[0042] Zinc stearate 1.0 parts

[0043] Silica 5 parts

[0044] Polyethylene glycol PEG4000 0.5 parts.

[0045] The preparation method of the wear-resistant agent for shoes: first pour polyolefin elastomer, silicone oil, TAIC, BIPB, zinc stearate, white carbon black, and polyethylene glycol into the internal mixer according to the above-mentioned weight ratio, and pour 110 °C for 8 minutes, then raised the temperature to 135 °C for 2 minutes, then discharged, and then kneaded and granulated to obtain the granular wear-resistant agent for shoes.

[0046] The preparation method of the test piece required for the wear resistance test: 100 parts of EVA 5110, 10 parts of talcum powder, 1 part of zinc oxide, 0.8 part of...

Embodiment 2

[0049] In this embodiment 2, the preparation method of a wear-resistant agent for shoes and the preparation method of the test piece are the same as the preparation method in embodiment 1, the difference is that in the raw material ratio:

[0050] 40 parts of silicone oil, 0.7 parts of zinc stearate, and 7 parts of white carbon black.

[0051] The DIN wear resistance results of the three test pieces prepared above are 182 mm 3 、170mm 3 、197mm 3 .

Embodiment 3

[0053]In this embodiment 3, the preparation method of a wear-resistant agent for shoes and the preparation method of the test piece are the same as the preparation method in embodiment 1, the difference is that in the ratio of raw materials:

[0054] Polyolefin elastomer 8411 45 parts, TAIC 0.3 parts, BIPB 0.3 parts, white carbon black 0 parts, polyethylene glycol PEG40000 parts.

[0055] The DIN wear resistance results of the three test pieces prepared above are 85 mm 3 、124mm 3 、116 mm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com