Gas soft nitriding process for stainless steel part

A technology of nitrocarburization and stainless steel, which is applied in the field of gas nitrocarburization process, can solve the problems that it is difficult to achieve a uniform, stable and qualified permeation layer in large quantities, the stainless steel nitrocarburization process is not perfect, and the number of parts in a single nitriding is not high, reaching Good stabilization effect, low consumption of gas raw materials, and large amount of single furnace charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

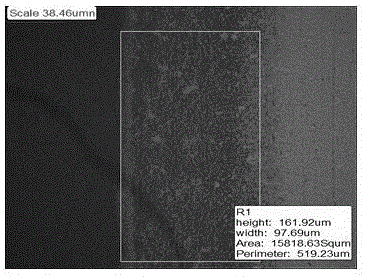

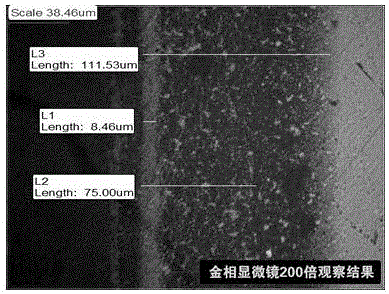

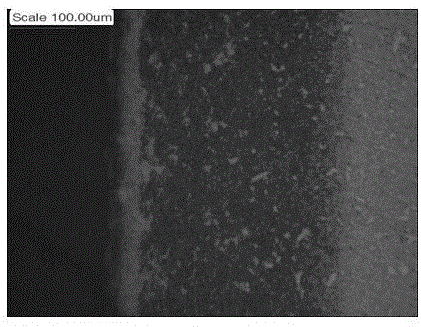

Image

Examples

Embodiment 1

[0031] Embodiments of the present invention: Embodiment 1: a kind of gas nitrocarburization process of stainless steel parts, the gas nitrocarburization process of this stainless steel parts is carried out according to the following steps:

[0032] 1) Degreasing cleaning: Use a cleaning agent to remove oil stains on the surface of the parts. The concentration of the cleaning agent is a 3% degreasing aqueous solution, and the degreasing temperature is 40°C;

[0033] 2) Nitrogen pretreatment: Soak the parts in the pretreatment solution. The temperature of the pretreatment solution during soaking is 30°C and the time is 10 minutes. Nitriding and nitriding uniformity;

[0034] 3) Pre-vacuumize: the product enters the furnace, and the furnace cover is sealed to vacuumize the nitriding furnace, and the vacuum degree is less than 20pa;

[0035] 4) Protective gas filling: Fill the nitriding furnace with nitrogen to a positive pressure of 5 cm water column, open the exhaust valve, adj...

Embodiment 2

[0045] Embodiment 2: a kind of gas nitrocarburization process of stainless steel parts, the gas nitrocarburization process of this stainless steel parts is carried out according to the following steps:

[0046] 1) Degreasing cleaning: Use a cleaning agent to remove oil stains on the surface of the parts. The concentration of the cleaning agent is 8% degreasing aqueous solution, and the degreasing temperature is 70°C;

[0047] 2) Nitrogen pretreatment: Soak the parts in the pretreatment solution. The temperature of the pretreatment solution during soaking is 50°C and the time is 40min. Nitriding and nitriding uniformity;

[0048] 3) Pre-vacuumizing: the product is put into the furnace, and the furnace cover is sealed to vacuumize the nitriding furnace, and the vacuum degree is less than 35pa;

[0049] 4) Protective gas filling: fill the nitriding furnace with nitrogen to a positive pressure of 20 cm water column, open the exhaust valve, adjust the exhaust valve exhaust volume,...

Embodiment 3

[0058] Embodiment 3: a kind of gas nitrocarburizing process of stainless steel parts, the gas nitrocarburizing process of this stainless steel parts is carried out according to the following steps:

[0059] 1) Degreasing cleaning: Use a cleaning agent to remove oil stains on the surface of the parts. The concentration of the cleaning agent solution is 5% degreasing aqueous solution, and the degreasing temperature is 50°C;

[0060] 2) Nitrogen pretreatment: Soak the parts in the pretreatment solution. The temperature of the pretreatment solution during soaking is 40°C and the time is 20 minutes. Nitriding and nitriding uniformity;

[0061] 3) Pre-vacuumizing: the product enters the furnace, and after the furnace cover is sealed, the nitriding furnace is vacuumed, and the vacuum degree is less than 25pa;

[0062] 4) Protective gas filling: fill the nitriding furnace with nitrogen to a positive pressure of 15 cm water column, open the exhaust valve, adjust the discharge volume o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com