A Gas Soft Nitriding Process for Stainless Steel Parts

A soft nitriding and stainless steel technology, applied in the field of gas soft nitriding process, can solve the problems of difficult to achieve uniform, stable and qualified infiltration layer in large quantities, imperfect stainless steel soft nitriding process, and low number of single nitriding parts, etc. Good stabilization effect, low consumption of gas raw materials, and large effect of single furnace loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

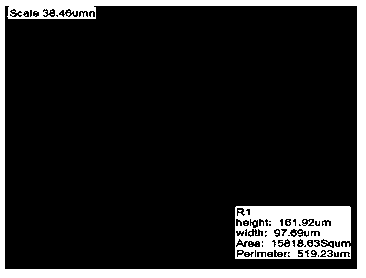

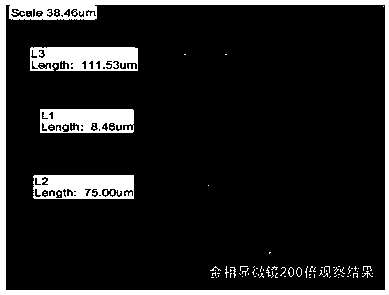

Image

Examples

Embodiment 1

[0031] Embodiments of the present invention: Embodiment 1: A gas nitrocarburizing process of stainless steel parts, the gas nitrocarburizing process of stainless steel parts is carried out according to the following steps:

[0032] 1) Degreasing cleaning: Use a cleaning agent to remove oil stains on the surface of the parts, where the concentration of the cleaning agent is a 3% degreasing aqueous solution, and the degreasing temperature is 40°C;

[0033] 2) Pre-nitrogen pretreatment: soak the parts in the pre-treatment liquid, the temperature of the pre-treatment liquid during immersion is 30℃, and the time is 10 minutes, which can improve the gas-nitrogen catalytic permeability of the parts and increase the ease of the parts in the nitrocarburizing. Nitrogen and nitriding uniformity;

[0034] 3) Pre-vacuum: the product enters the furnace, the nitriding furnace is vacuumed after the furnace cover is sealed, and the vacuum degree is less than 20pa;

[0035] 4) Shielding gas filling: op...

Embodiment 2

[0045] Embodiment 2: A gas nitrocarburizing process of stainless steel parts, the gas nitrocarburizing process of stainless steel parts is carried out according to the following steps:

[0046] 1) Degreasing cleaning: Use a cleaning agent to remove oil stains on the surface of the parts, where the concentration of the cleaning agent solution is 8% degreasing water solution, and the degreasing temperature is 70°C;

[0047] 2) Nitrogen pretreatment: soak the parts in the pretreatment liquid, the temperature of the pretreatment liquid during immersion is 50℃, and the time is 40min, which can improve the gas nitrogen permeability of the parts and increase the ease of the parts during nitrocarburizing. Nitrogen and nitriding uniformity;

[0048] 3) Pre-vacuum: the product enters the furnace, the nitriding furnace is vacuumed after the furnace cover is sealed, and the vacuum degree is less than 35pa;

[0049] 4) Shielding gas filling: open the exhaust valve when filling the nitriding furnac...

Embodiment 3

[0058] Embodiment 3: A gas nitrocarburizing process of stainless steel parts, the gas nitrocarburizing process of stainless steel parts is carried out according to the following steps:

[0059] 1) Degreasing cleaning: Use a cleaning agent to remove oil stains on the surface of the parts, where the concentration of the cleaning agent is a 5% degreasing aqueous solution, and the degreasing temperature is 50°C;

[0060] 2) Pre-nitrogen pretreatment: soak the parts in the pre-treatment liquid, the temperature of the pre-treatment liquid during soaking is 40℃, and the time is 20min, which can improve the gas-nitrogen catalytic permeability of the parts and increase the ease of the parts in the nitrocarburizing. Nitrogen and nitriding uniformity;

[0061] 3) Pre-evacuation: the product enters the furnace, the nitriding furnace is vacuumed after the furnace cover is sealed, and the vacuum degree is less than 25pa;

[0062] 4) Shielding gas filling: Open the exhaust valve when filling the nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com