Weft yarn detection device for air-jet loom

A technology of air-jet loom and detection device, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as difficulty in checking the state of weft yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

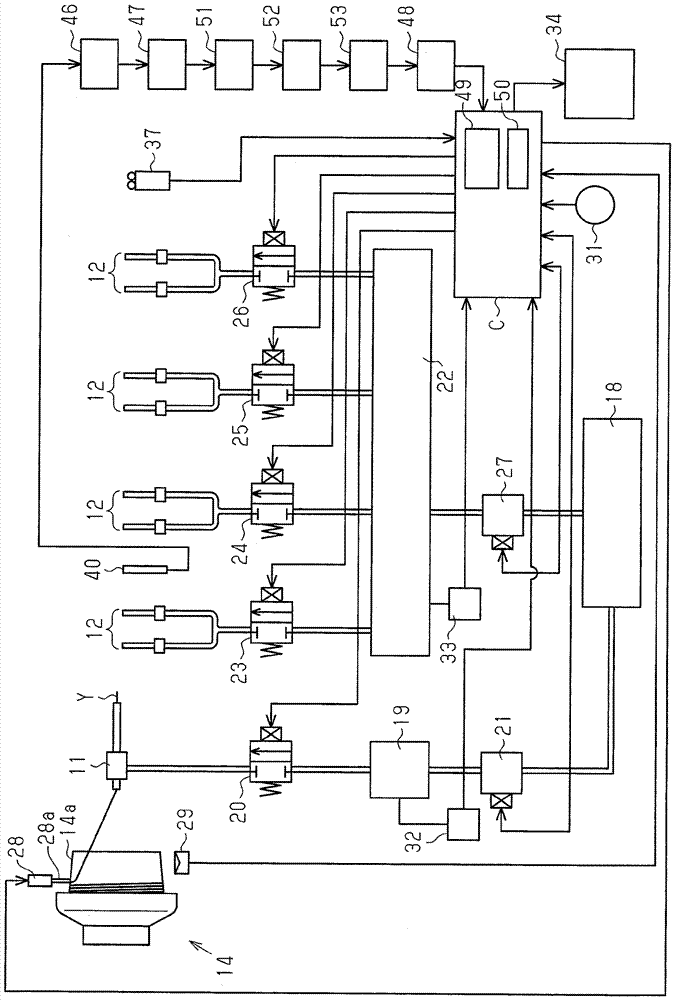

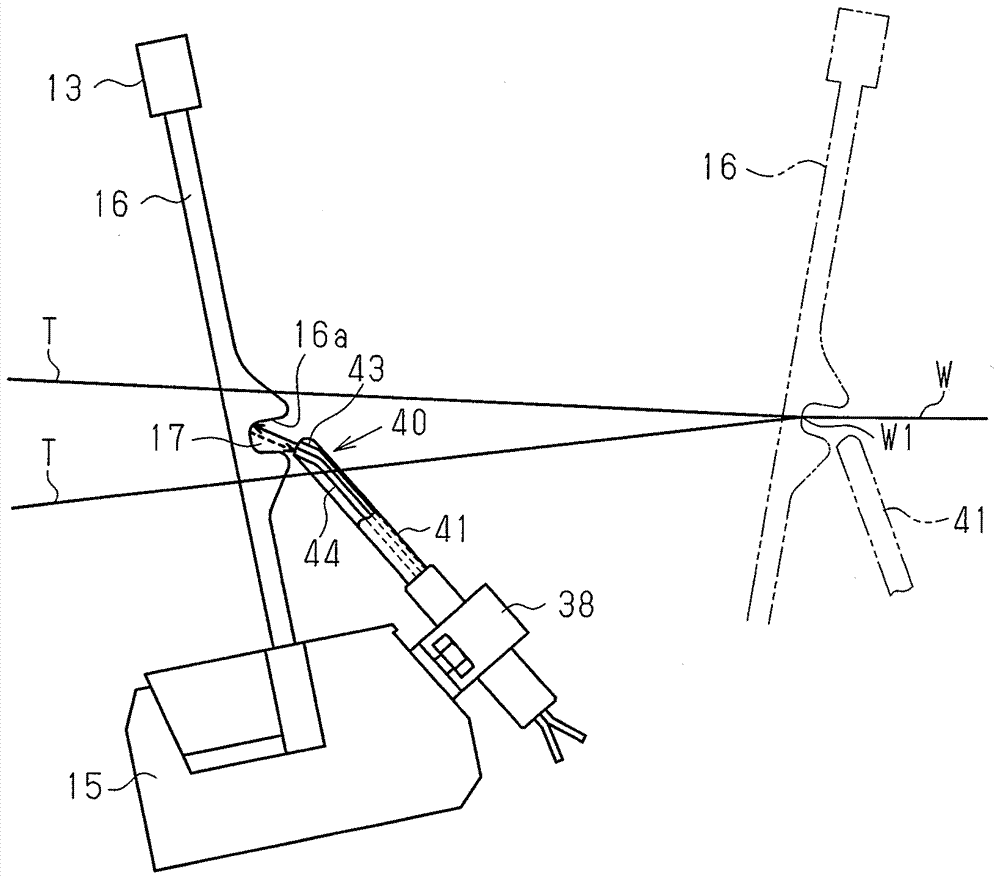

[0031] A first embodiment of the invention will now be referred to Figure 1-8 to describe.

[0032] like figure 1 and figure 2 Shown, air-jet loom comprises main nozzle 11 for weft insertion, a plurality of auxiliary nozzles 12 for weft insertion, reed 13 (shown in figure 2 ) and weft measuring and storage device 14 (shown in figure 1 middle). like figure 2 As shown, the main nozzle 11 , the auxiliary nozzle 12 and the reed 13 are fixed to the sley 15 . The reed 13 comprises teeth 16 arranged in the weft insertion direction. Each tooth 16 has a guide recess 16a. The guide recesses 16a of the teeth 16 form the reed channels 17 .

[0033] like figure 1 As shown, the main nozzle 11 is connected via piping to a main nozzle tank 19 for the main nozzle 11 . The main nozzle tank 19 is connected to the source pressure tank 18 . The electromagnetic switch valve 20 is provided between the main nozzle 11 and the main nozzle tank 19 . The jet of pressurized air for weft...

no. 2 example

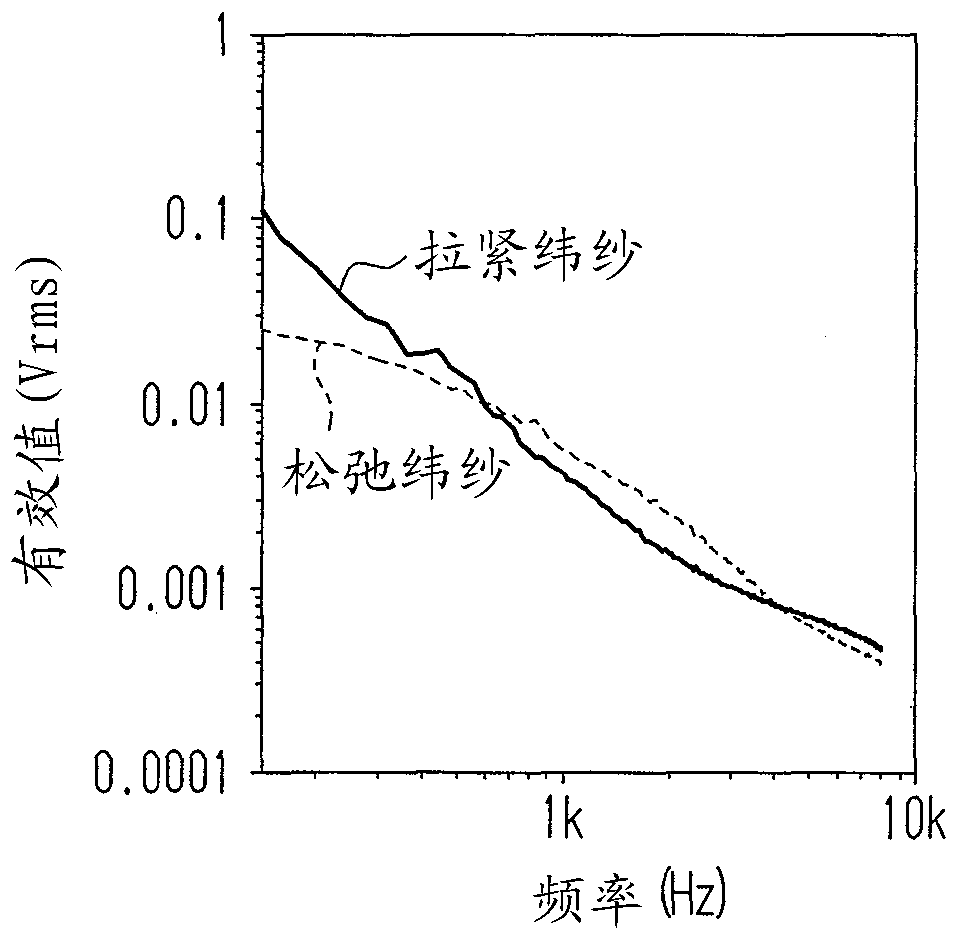

[0063] will now refer to Figures 9 to 16 A second embodiment is described. The second embodiment differs from the first embodiment in that the estimating section (CPU 49) does not estimate the time point of maximum tension as the time when the output signal value from the signal processor (band pass filter 47) drops to a predetermined threshold value. time point, but the time point of maximum tension is estimated by the integration method. Components that are the same as or similar to those of the first embodiment will not be described again.

[0064] like Figure 9 As shown, a full-wave rectifier 51 , an averaging circuit 52 and an integrating circuit 53 are provided between the band-pass filter 47 and the A / D converter 48 as hardware components. A full-wave rectifier 51 , an averaging circuit 52 , and an integrating circuit 53 are arranged in this order from the band-pass filter 47 .

[0065] Figure 10 Changes in the crank angle 0° signal, the output signal of the ban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com