A Composite Vibration Isolation Device Based on Particle Damping and Memory Alloy Materials

A technology of memory alloy and particle damping, applied in roads, tracks, buildings, etc., can solve problems such as cracking of residential buildings, sudden heart attacks of residents, and failure of precision instruments, achieving good durability, improved vibration isolation effect, and reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

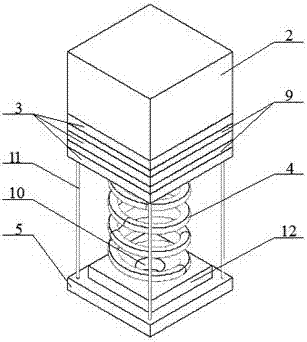

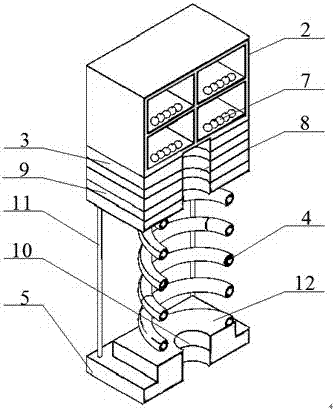

[0030] Such as Figure 1~6 As shown, the present invention is a composite vibration isolation device based on particle damping and memory alloy materials, including an inner chamber covering material 1, a particle storage chamber 2, a multilayer board 3, a spring 4, a bottom plate 5, a particle outer covering material 6, and steel balls 7. First bolt 8 and second bolt 10, polymer material 9 (using rubber), memory alloy strip 11 and backing plate 12. First, several rectangular steel plates are welded into 4 chambers to form a granule holding room. The inner chamber covering material 1 is made of soft bags, the granule outsourcing material 6 is made of granule outsourcing soft bags, and the granule 7 is made of steel balls. Bond the soft bag, put the steel balls wrapped in the soft bag with particles, and then weld a rectangular plate through the fillet weld in the forward direction of the section to form a closed particle storage chamber 2; the multi-layer board 3 (using steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com