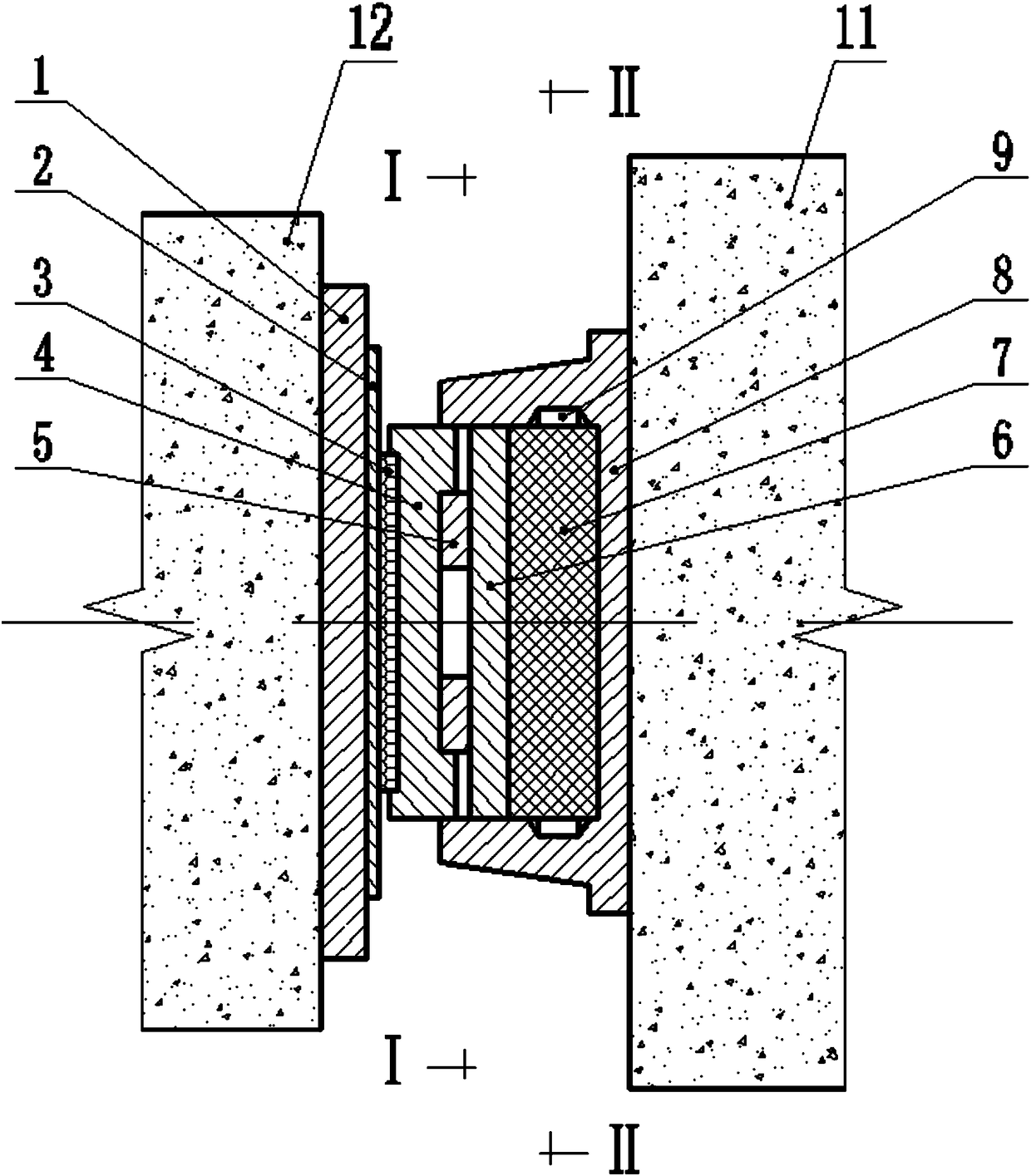

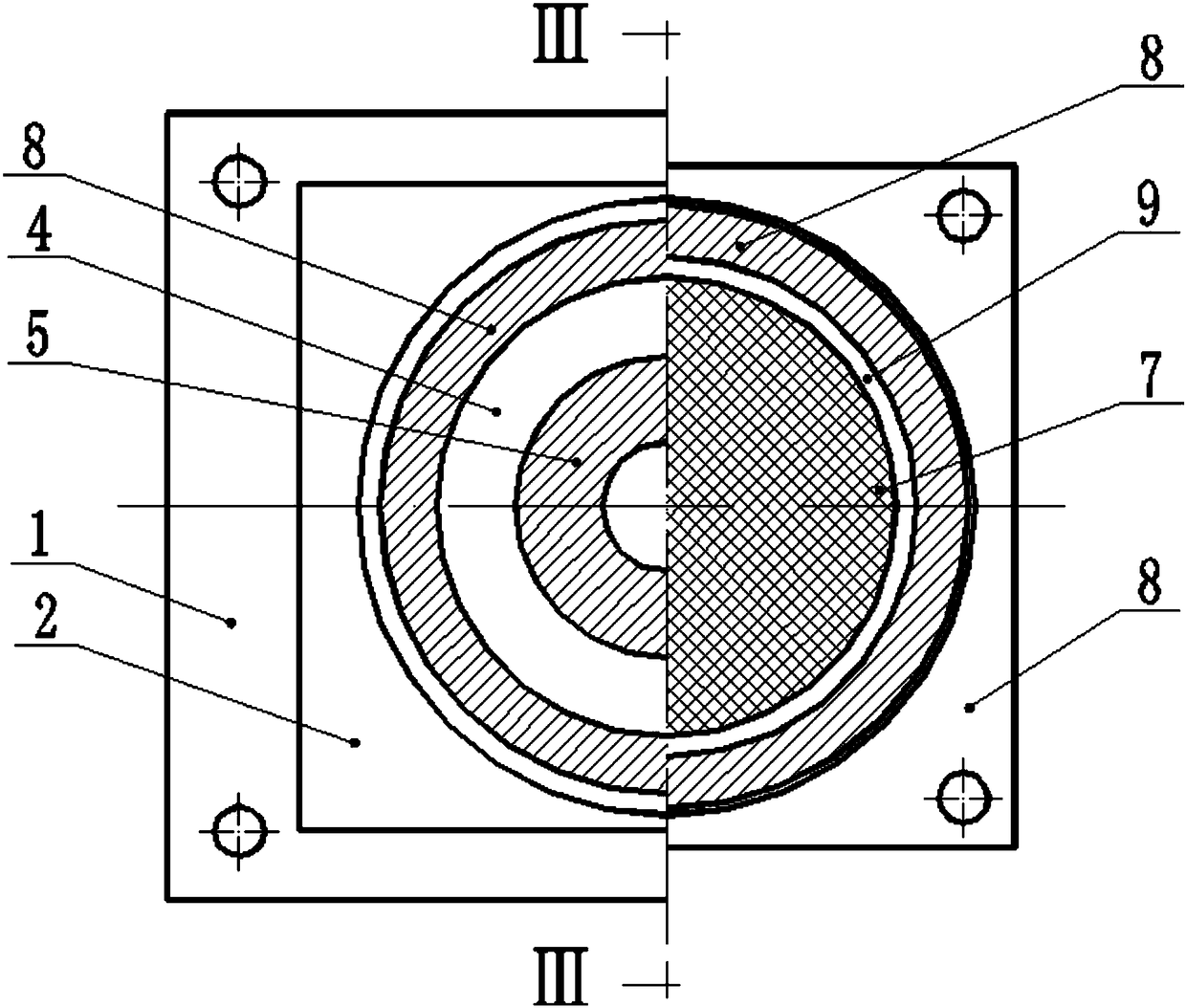

Anti-collision high elastic support in horizontal direction

A horizontal, anti-collision technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of small elastic deformation, large size, small bearing capacity of a single butterfly spring, etc., and achieve increased bearing capacity and large elastic support. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0066] In the first embodiment of the present invention, the sum of the depths of the first groove and the second groove of the liner 4 does not exceed half of the thickness of the liner 4 .

[0067] In a preferred embodiment of the present invention, wherein, the outer peripheral wall of the elastic plate 7, the force diffusion plate 6 and / or the liner 4 is in abutment contact with the inner peripheral wall of the accommodation space of the bottom basin 8, that is, just fills the bottom basin 8 accommodation space.

[0068] In the embodiment of the present invention, the bottom pan 8, the force spreading plate 6, the lining plate 4 and / or the top support plate 1 can be made of steel, and the elastic plate 7 can be made of high elastic material such as rubber or polyurethane.

[0069] In an embodiment of the present invention, no stainless steel plate 2 may be provided between the top brace plate 1 and the friction-reducing plate 3, for example, the top brace plate 1 may direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com