A hoisting portal frame and its application method in the construction of special-shaped antisymmetric steel main tower

A special-shaped antisymmetric and steel main tower technology, which is applied in the direction of erecting/assembling bridges, bridge parts, bridge materials, etc., can solve the problems of long-term occupation of large hoisting equipment, susceptibility to water level changes, and insufficient stability of floating cranes. Achieve the effects of shortening the construction period, good construction stability, and fast lifting and moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

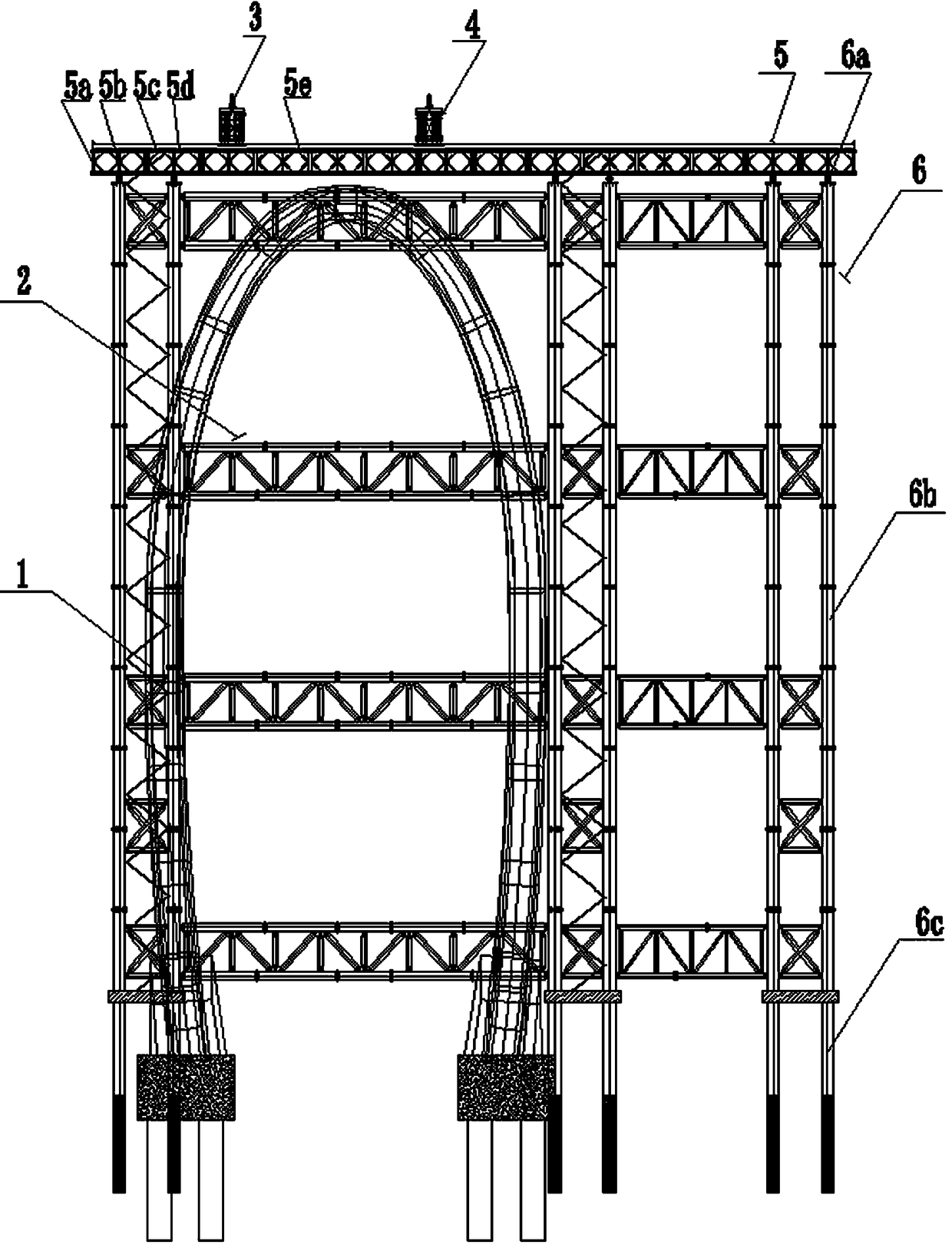

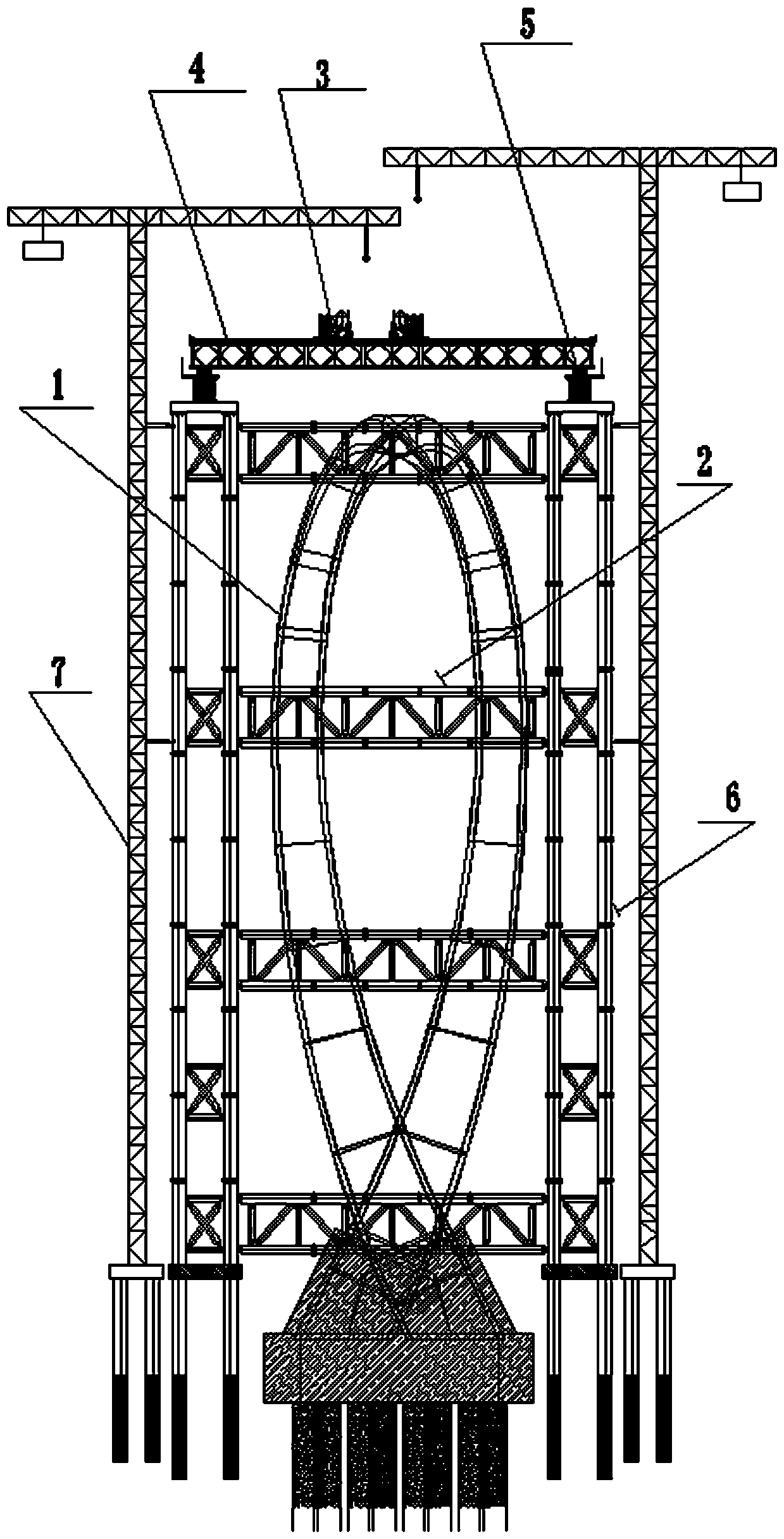

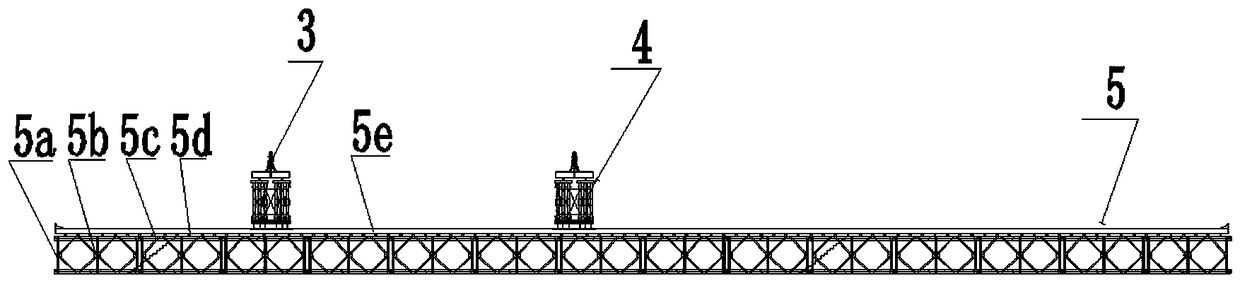

[0037] Such as figure 1 with figure 2 As shown, a hoisting gantry includes a support device and a slideway device. The support device includes a vertical support structure 6 and a horizontal connection structure 2 arranged at intervals between the vertical support structures 6. The horizontal connection structure 2 can be arranged according to the vertical The height of the support structure 6 is provided with 4 to 8 floors; the vertical support structure 6 includes several first longitudinal beam units, and each first longitudinal beam unit includes four first longitudinal beams surrounded by a cube and two connecting The first distribution beam 6a at the upper end of the first longitudinal beam, the first distribution beam 6a is preferably made of 2 layers of 4I56a I-beam, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com