An Assembled Work Well Standard Section and Its Installation Method in New Construction

A standard section and assembled technology, which is applied in water conservancy engineering, infrastructure engineering, construction, etc., can solve the problems of large volume and quality of prefabricated reinforced concrete wells, inconvenient transportation and installation, and difficulty in guaranteeing construction quality. High efficiency, simple installation method and flexible size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

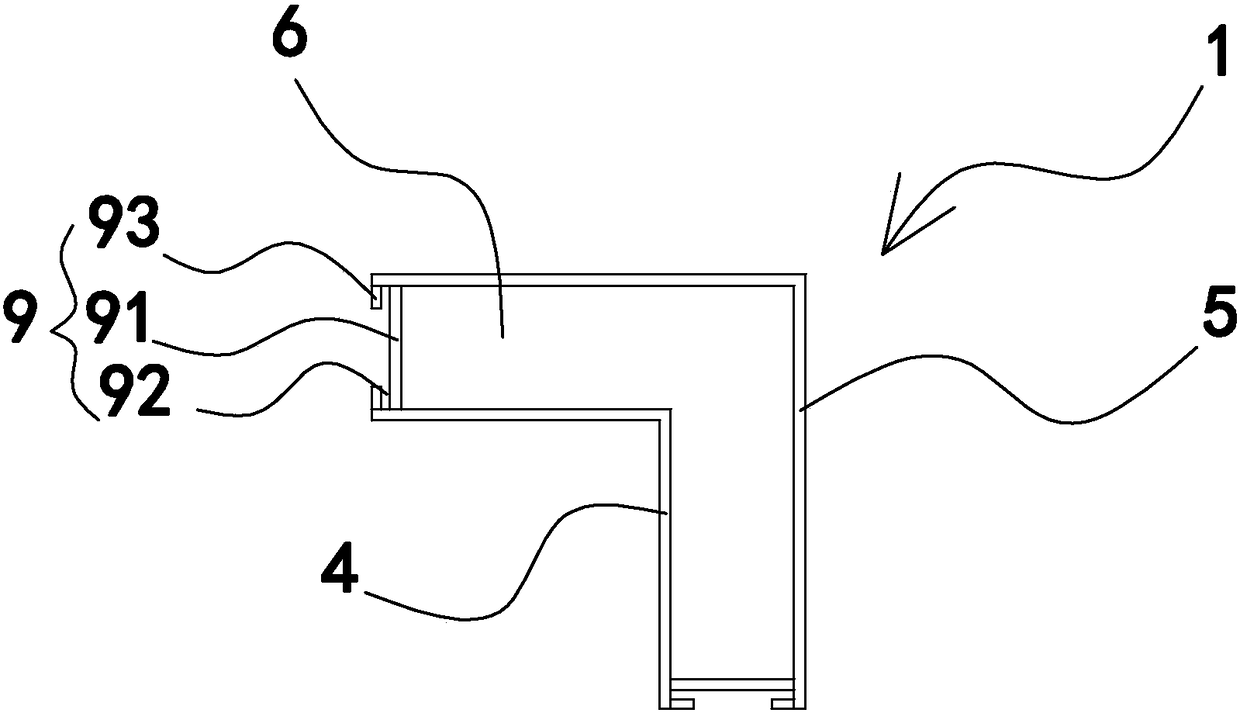

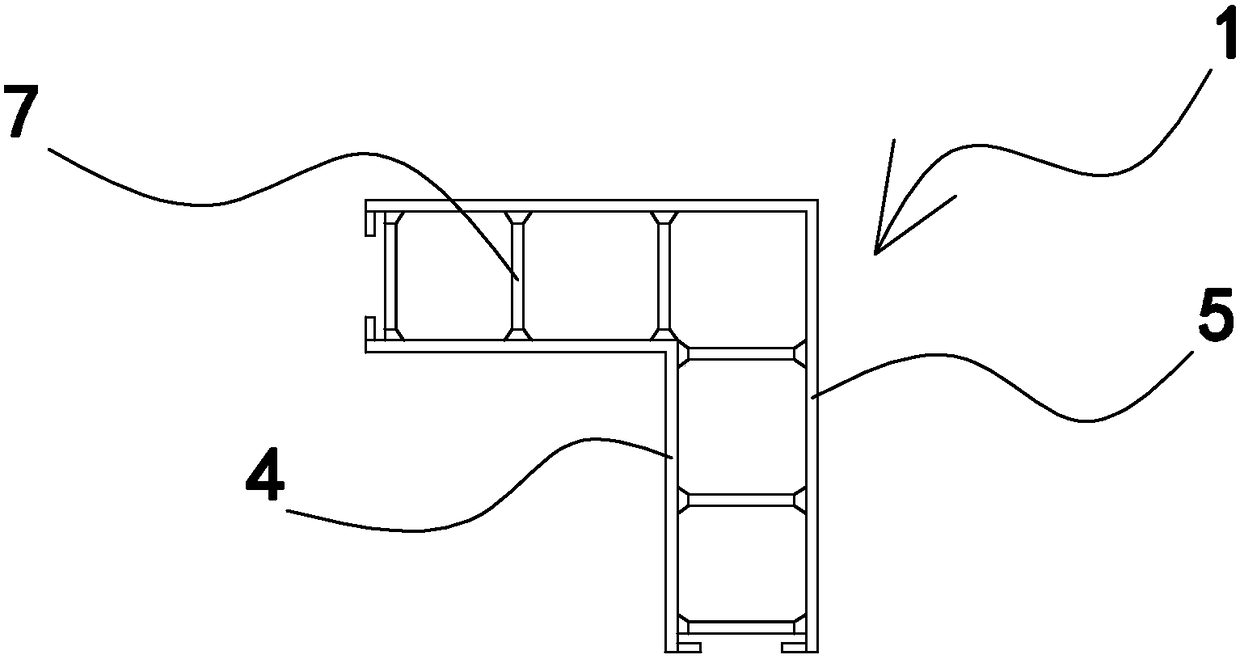

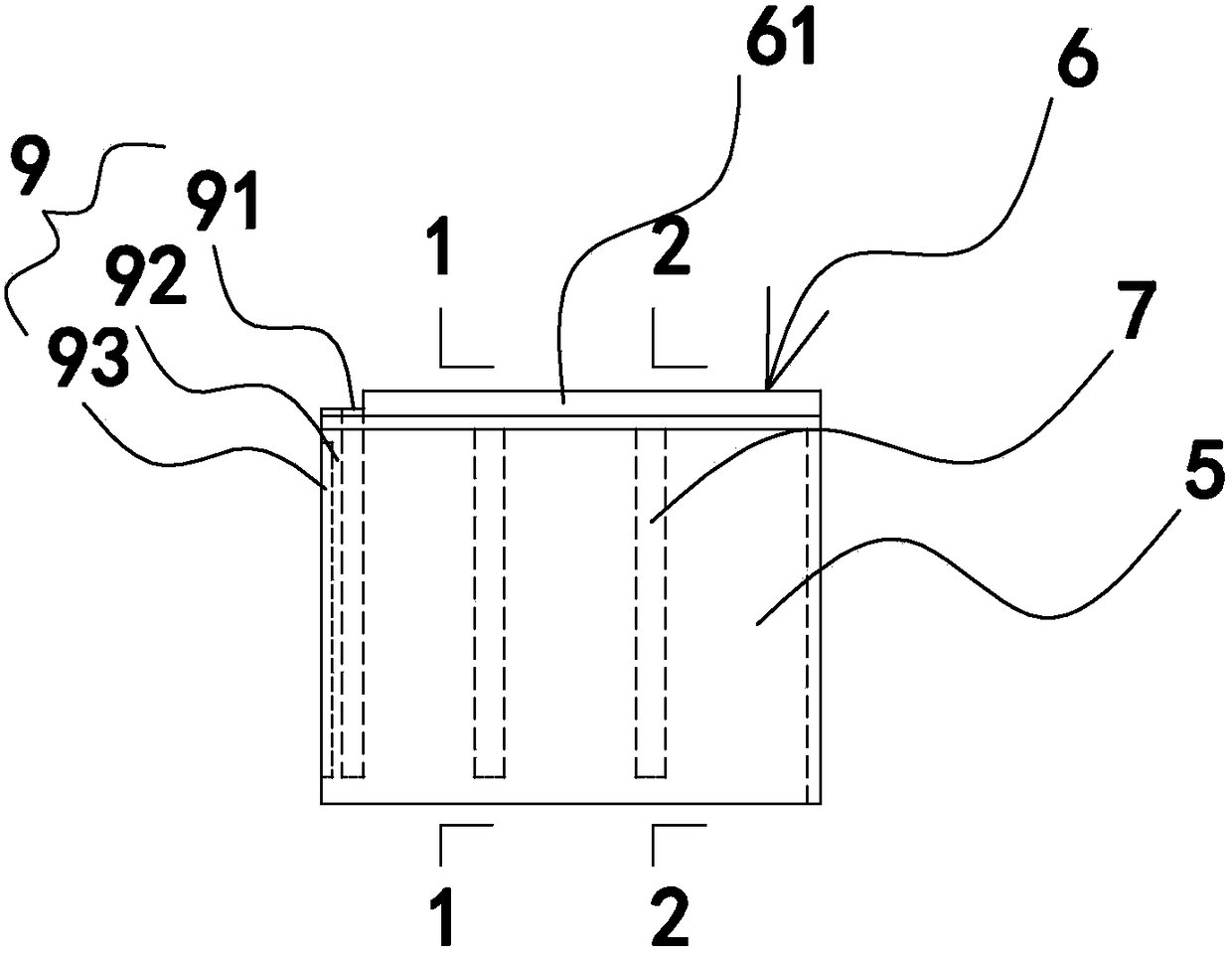

[0052] Such as figure 1 , 2 , 3, 4, 5 and 6, the assembled work well standard section includes an assembly and a connector 3, the assembly includes an inner plate 4 and an outer plate 5, and several The longitudinal rib 7 is provided with a transverse rib 6 on the top, and the inner and outer plates 4 and 5 are connected to the transverse rib 6 through the longitudinal rib 7. The protrusion forms a bump 61, and its bottom is provided with a groove 8 matching the bump 61. During assembly, the bump 61 is inserted into the groove 8 of the assembly of the adjacent well standard section 10 to realize connection. The bottom surface of the longitudinal rib 7 is slightly higher than the bottom surface of the inner plate 4 and the outer plate 5 and forms a groove 8 with the bottom surface of the inner plate 4 and the outer plate 5. The bottom surfaces of the plate 4 and the outer plate 5 are flush, and the above-mentioned groove 8 is opened on the bottom surface of the longitudinal r...

Embodiment 2

[0073] The difference between this embodiment and Embodiment 1 is that: Figure 17 with 18As shown, the cable pipe port 13 is located between the two working well standard joints, so the two working well standard joints are the opening standard joints, and the lower hole 101a mark is made on the two working well standard joints, and then the on-site opening The holes are either not removed and directly drilled on the hole standard joint, or the two standard joints of the well have been prefabricated in the factory in advance. All the connectors 3 on the standard section of the labor well are not located on the orifice 101a. Other structures, principles and installation methods are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com