Hyperbola cross truss formed steel construction cooling tower

A cooling tower and hyperbolic technology, applied in the field of cooling towers, can solve the problems of heavy weight and long construction period, and achieve the effects of fast speed, simple construction and low steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

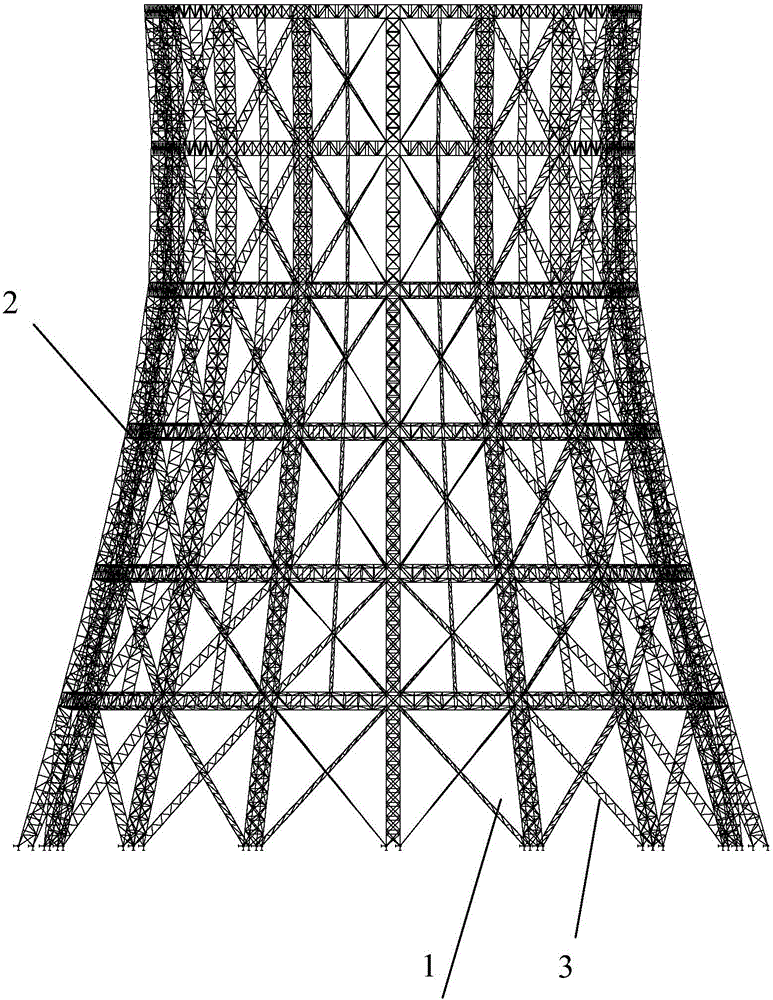

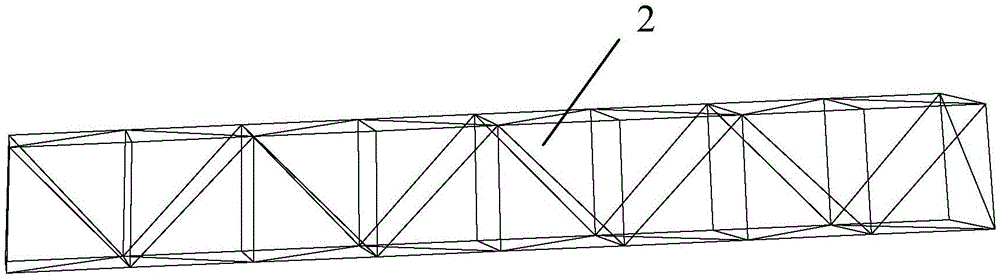

[0025] Such as figure 1 As shown, the hyperbolic cross truss steel structure cooling tower includes:

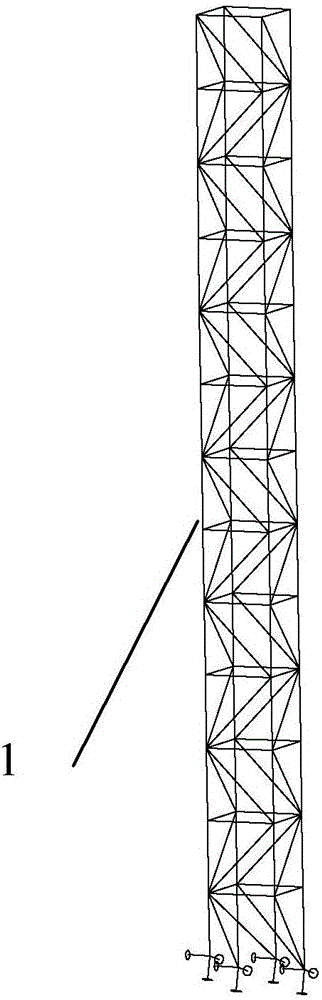

[0026] The truss column 1 is set on the foundation of the cooling tower and is set along the height direction. The truss column 1 can be set along the height direction and can extend from the bottom foundation to the top of the cooling tower, which is to transfer the overall load of the cooling tower to the foundation. The main force-bearing structure, the number of the truss columns 1 is multiple, and the plurality of truss columns 1 are arranged in a ring, such as figure 2 As shown, each of the truss columns 1 adopts a three-dimensional truss structure; a single truss column 1 needs to be connected and manufactured in the factory. connection, welded connection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com