Method for identifying and setting degree-of-overlapping of steam admission regulating valves for steam turbine

A technology for regulating valves and overlapping degrees, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problem of lack of broad-spectrum applicable implementation standards or basis for setting regulating valve overlapping degrees, and reduce inherent throttling losses , the effect of efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

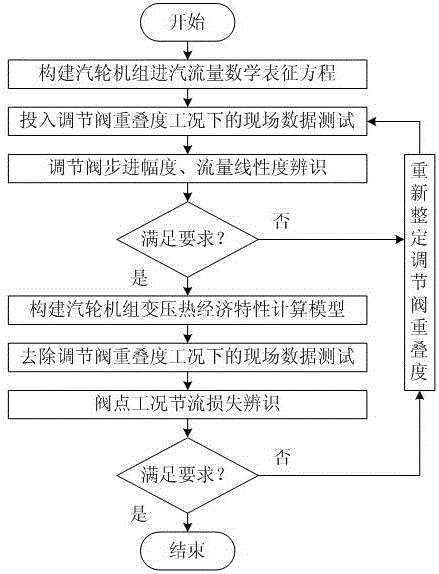

[0023] An embodiment of the present invention is a steam turbine inlet steam regulating valve overlap identification and setting method. The technical solution in the embodiment of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiment of the present invention:

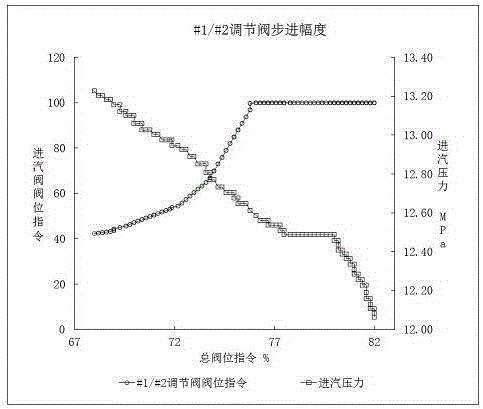

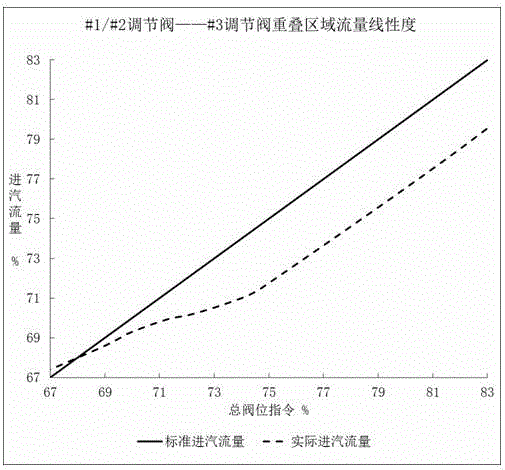

[0024] No. 6 steam turbine in a power plant is a subcritical, intermediate reheat, two-cylinder, two-exhaust, condensing steam turbine of N300-16.7 / 537 / 537-8 type (high and medium pressure combined cylinder) manufactured by Dongfang Steam Turbine Factory; the steam distribution mechanism of the steam turbine The nozzle steam distribution method is adopted, and the four high-pressure steam inlet regulating valves are equipped with two valve management methods of single valve and sequence valve. In the sequence valve mode, the opening sequence of the regulating valve is CV1 / 2→CV3→CV4.

[0025] Step 1: Construct the mathematical characterization equation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com