Electronically controllable pneumatic brake system in a utility vehicle and method for electronically controlling a pneumatic brake system

A pneumatic braking and electronic control technology, applied in the direction of braking safety system, braking control system, braking transmission device, etc., can solve problems such as unfavorable braking force distribution and limited braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

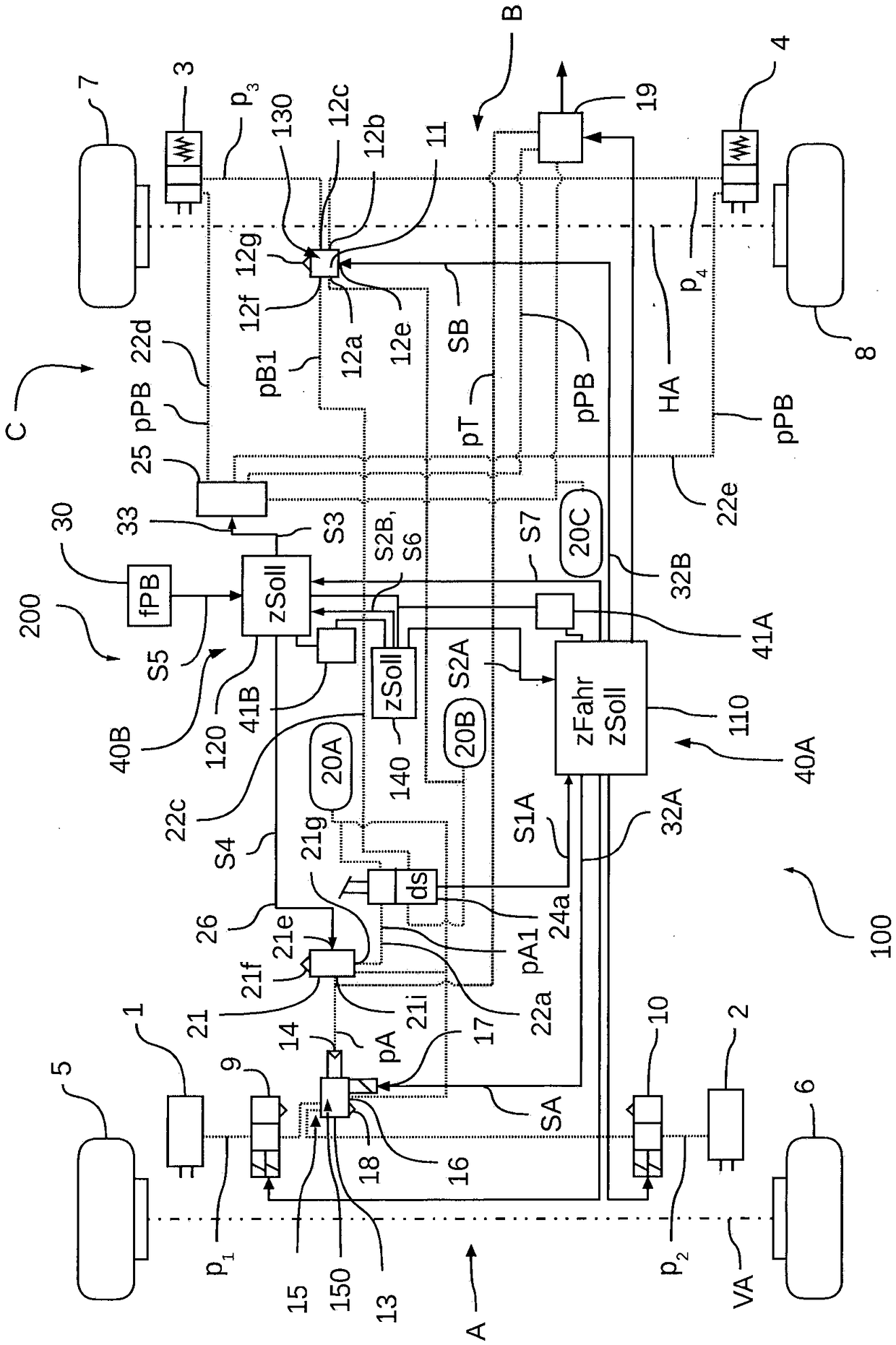

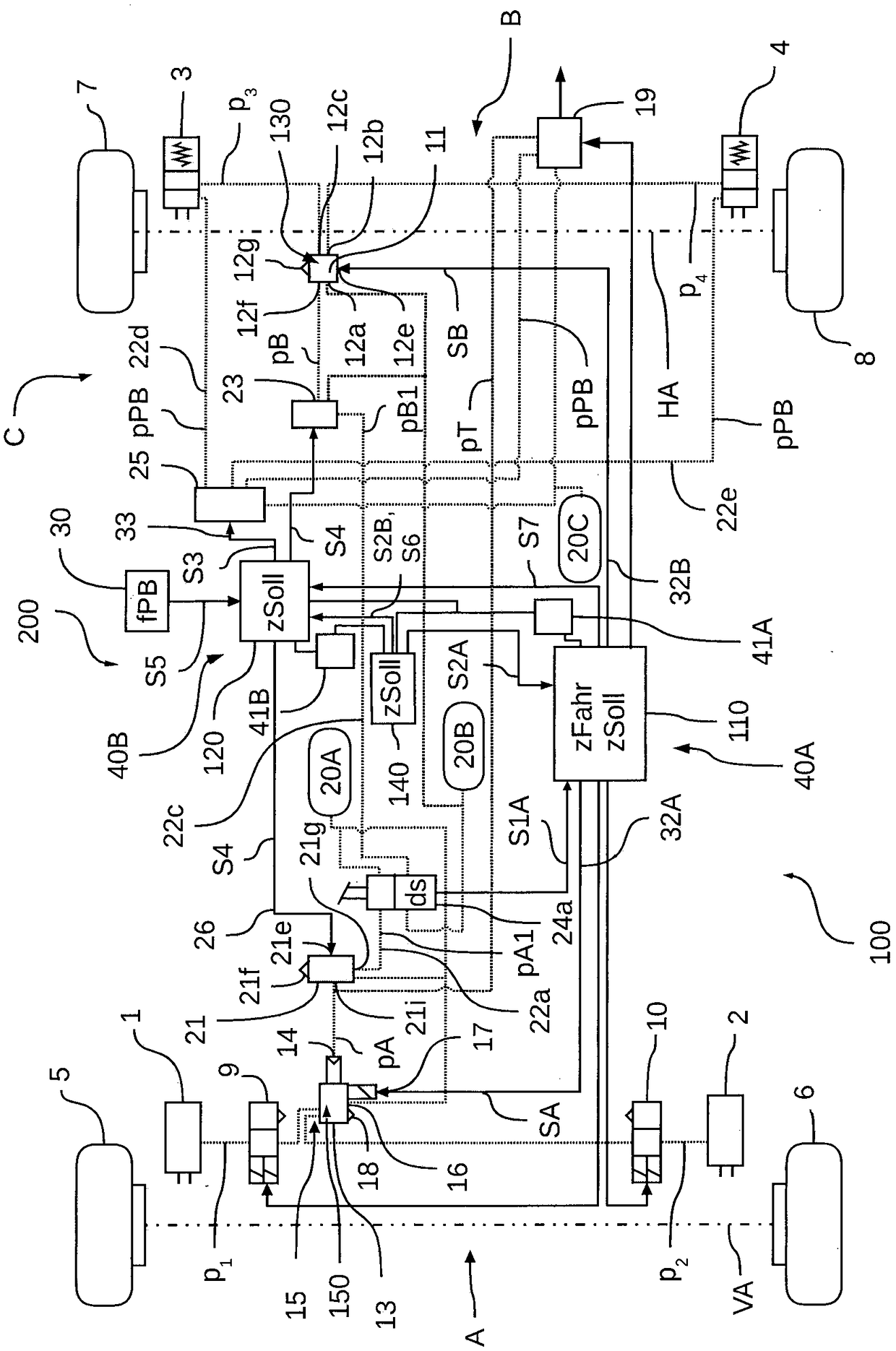

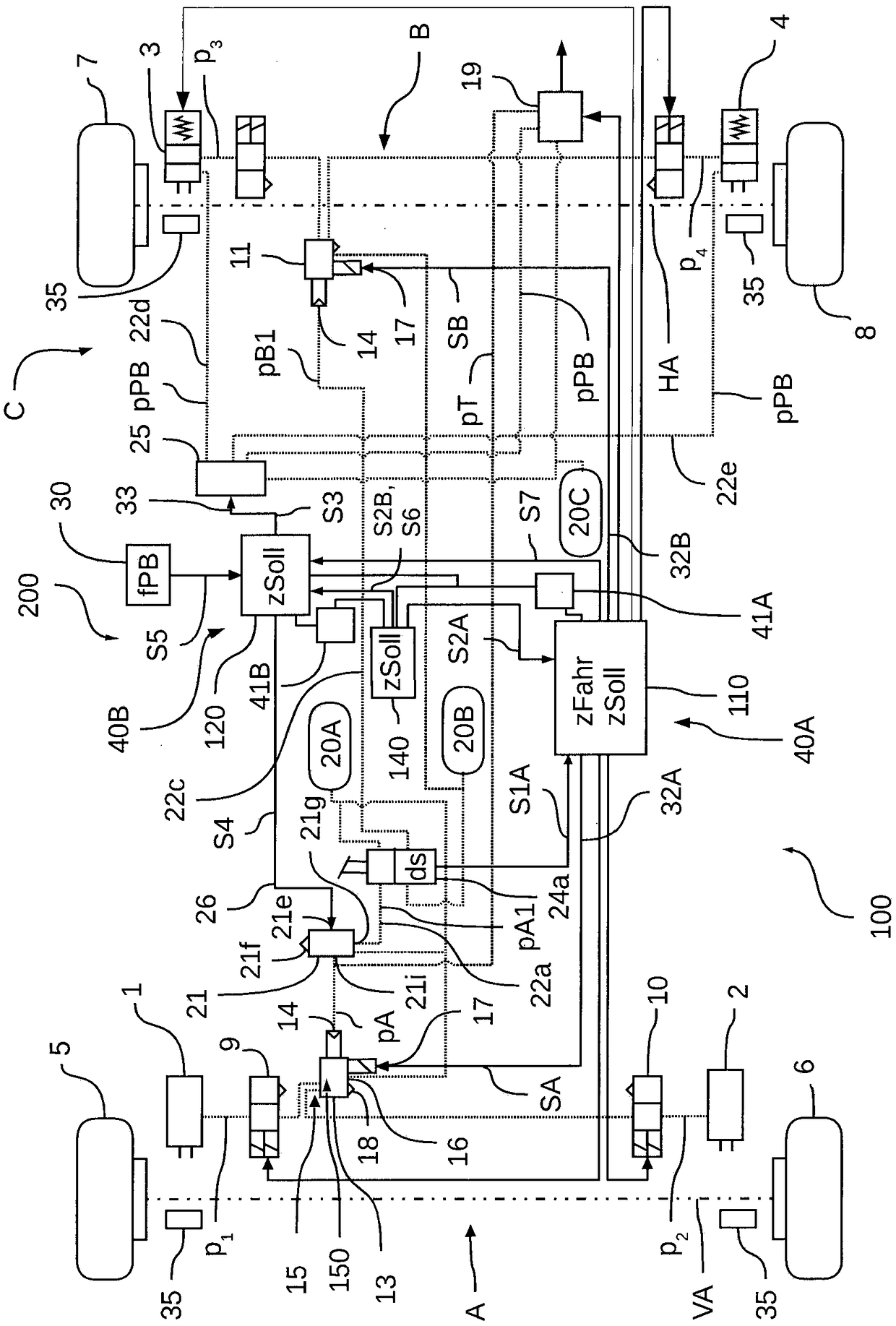

[0053] according to figure 1 The exemplary embodiment relates to an electronically controlled pneumatic braking system EBS 100 in a commercial vehicle 200 with wheel brakes 1 , 2 , 3 , 4 on wheels 5 , 6 , 7 , 8 . According to the embodiment shown, the wheel brakes 1 , 2 , 3 , 4 are actuated in three brake circuits A, B, C, wherein the first brake circuit A concerns the wheels 5 , 6 of the front axle VA The wheel brakes 1, 2 of the brake circuit 1 and the second and third brake circuits B, C relate to the wheel brakes 3, 4 on the wheels 7, 8 of the rear axle HA.

[0054] On the wheels 5 , 6 of the front axle VA, the usual ABS brake valves 9 , 10 are connected to the wheel brakes 1 of the first brake circuit A in order to regulate the brake pressures P1 , P2 as a function of the detected ABS slipping situation. , 2 before. At the driven wheels 7 , 8 of the rear axle HA, according to this embodiment, an axle modulator 11 is connected upstream of the wheel brakes 3 , 4 in the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com