Water lubrication spherical bearing for ship shaftless rim propeller

A spherical bearing and propeller technology, applied in shafts and bearings, sliding contact bearings, bearing components, etc., can solve the problems of many parts and complex structures, and achieve the goal of improving bearing capacity, increasing bearing area, and improving suction capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

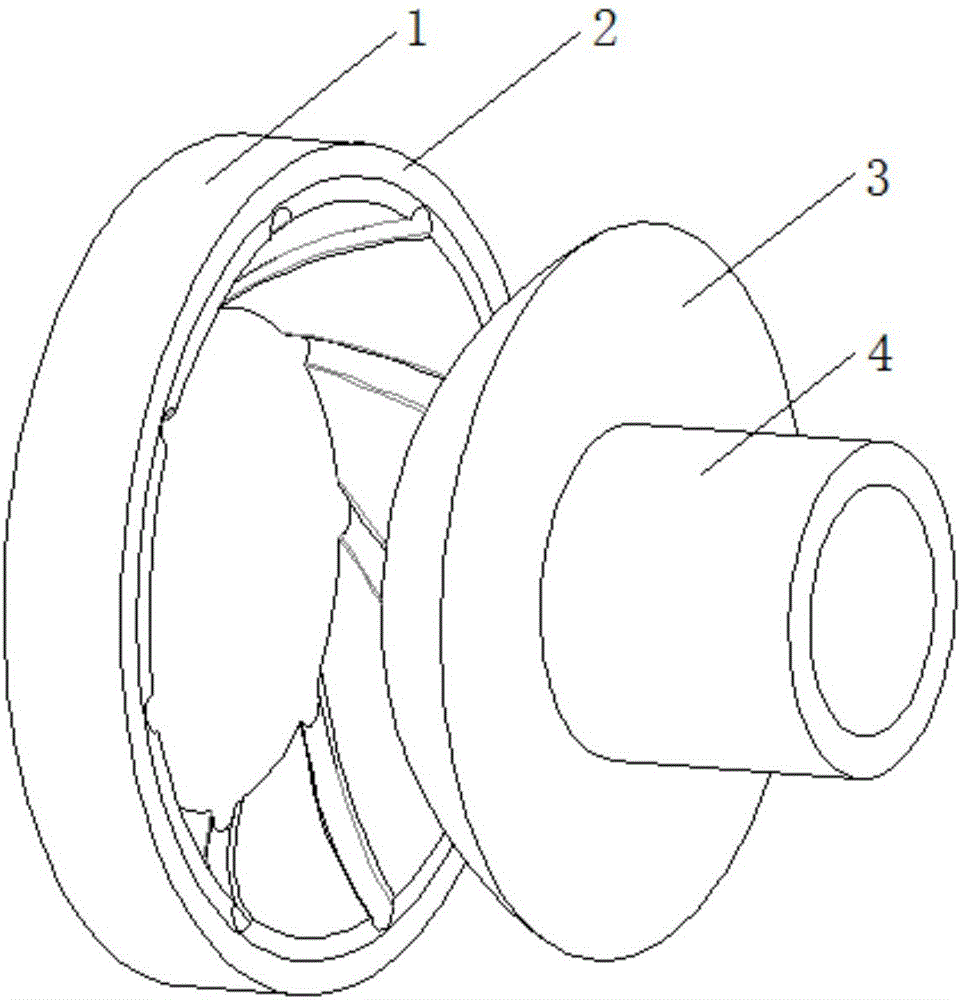

[0026] The water-lubricated spherical bearing (bearing for short) used for the ship's shaftless rim propeller provided by the present invention has a structure such as figure 1 As shown, it is mainly composed of a metal tile base 1 , a pressure plate 3 , a shaft 4 connected in sequence, and a rubber lining 2 connected with the metal tile base 1 .

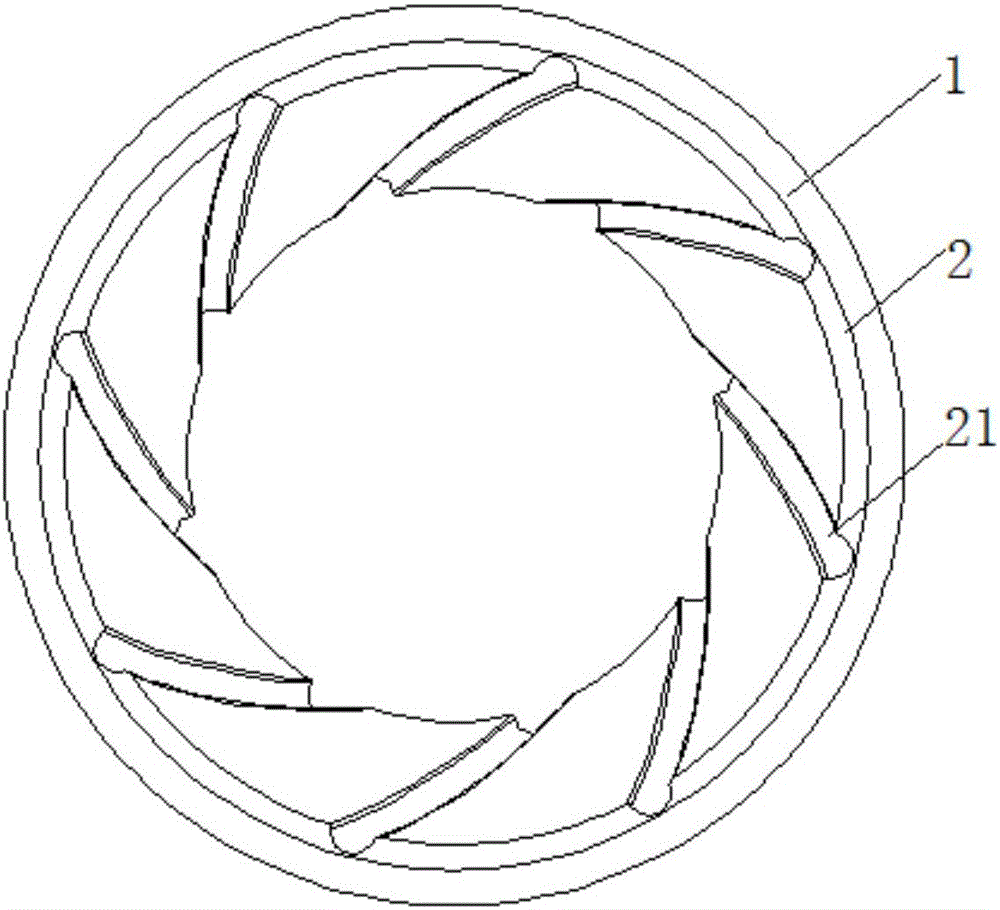

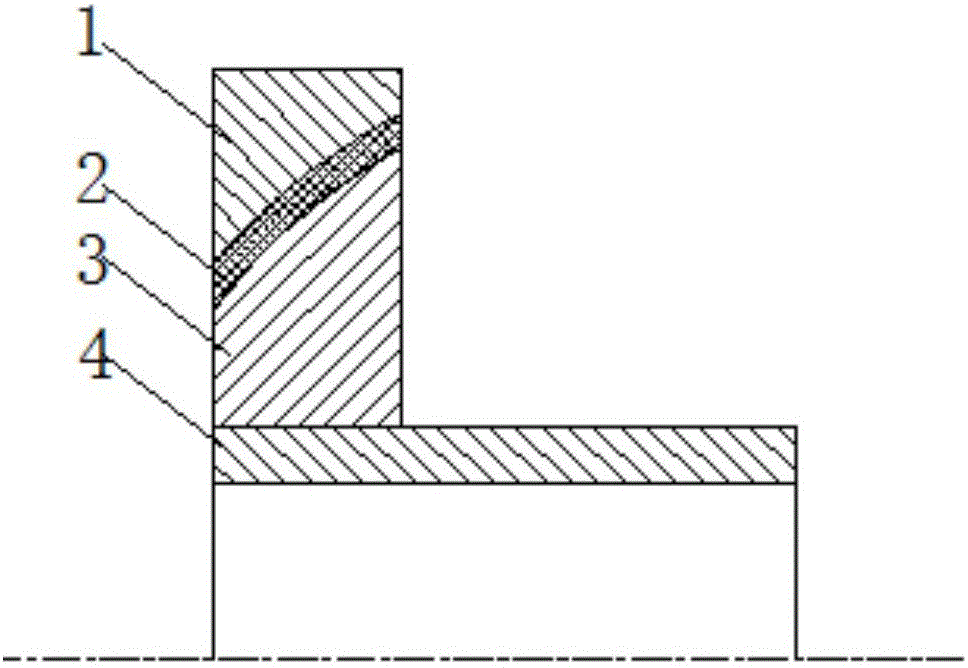

[0027] The metal tile base 1 is a ring structure, and its inner surface is a spherical surface. The radius of the spherical surface is the same as the contact surface of the rubber lining 2. The spherical surface radius can be obtained by evaluating the bearing capacity.

[0028] The rubber lining 2 is formed by being tightly bonded to the spherical surface of the metal tile base 1 through a vulcanization process. Besides, there is no need for any other connecting par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com