Yaw brake and wind power generator using the yaw brake

A yaw brake and wind turbine technology, which is applied to wind turbines, wind turbine control, wind power generation and other directions, can solve the problems of poor detection accuracy and high cost, and achieve the effects of accurate wear conditions, simple structure and convenient observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

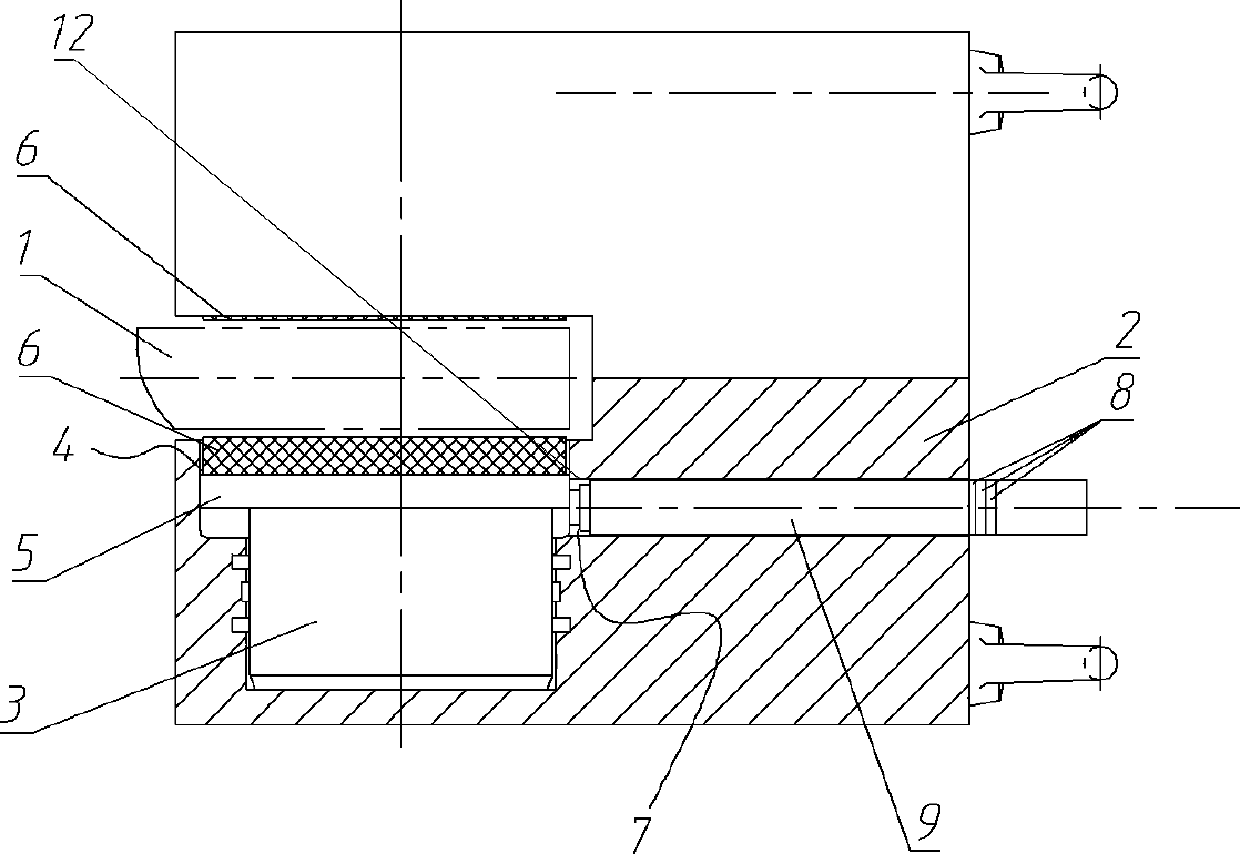

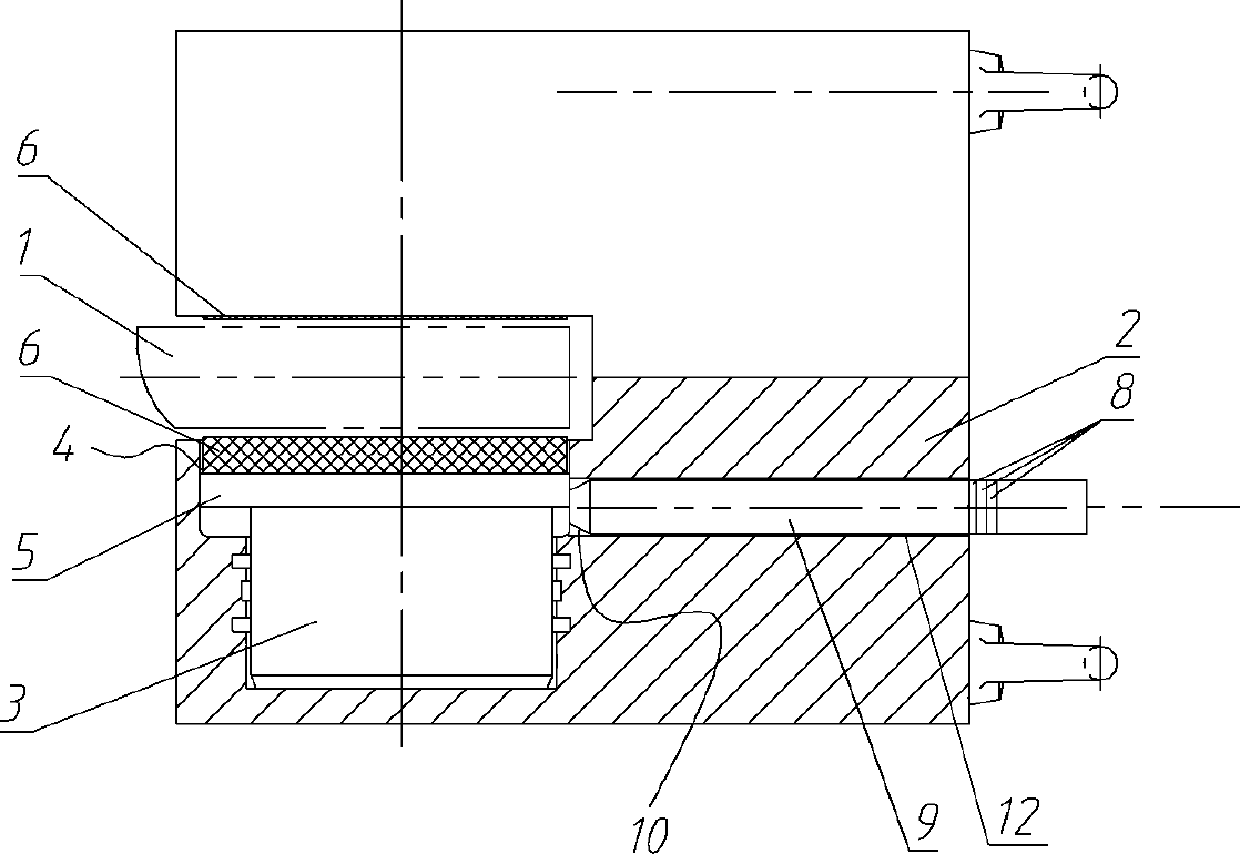

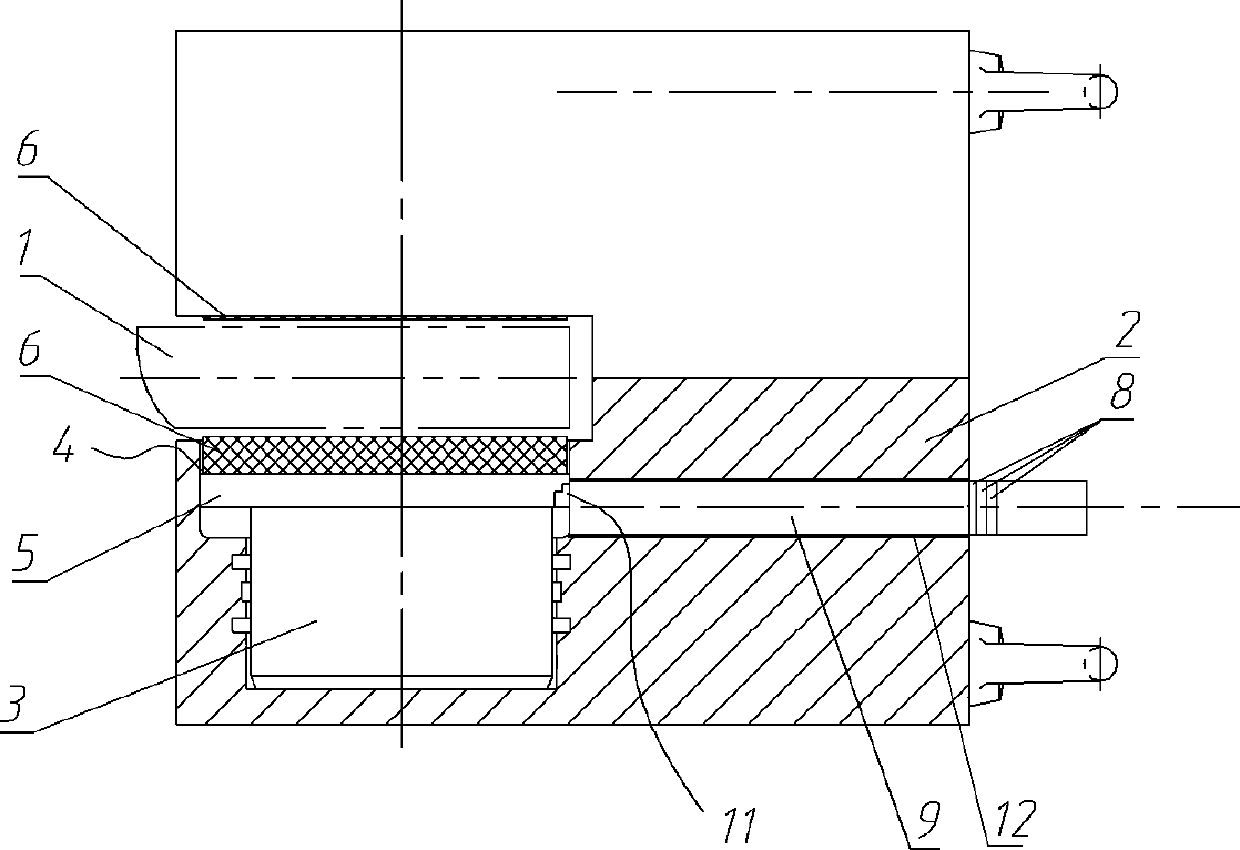

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Embodiments of the yaw brake of the present invention are as figure 1 As shown, it includes a caliper body 2 , a friction plate 4 movable vertically on the caliper body 2 , and an oil cylinder 3 for driving the friction plate 4 to clamp or release the brake disc 1 . The friction plate 4 includes a friction plate base plate 5 and a friction material plate 6 arranged on the top surface of the friction plate base plate 5 .

[0025] Definition The transverse direction is the direction perpendicular to the clamping movement direction of the friction plate 4. A transverse through hole is provided on the outer surface of the caliper body 2 to form a detection tool insertion hole 12. The inner end of the detection tool insertion hole 12 faces the friction plate substrate 5 . The friction sheet substrate 5 is a flat plate structure, with a bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com