Rectification noise reduction air duct

A technology for air outlet and noise reduction, which is applied in the direction of pipes, pipe components, rigid pipes, etc., and can solve the problem of air flow obstruction in the air outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

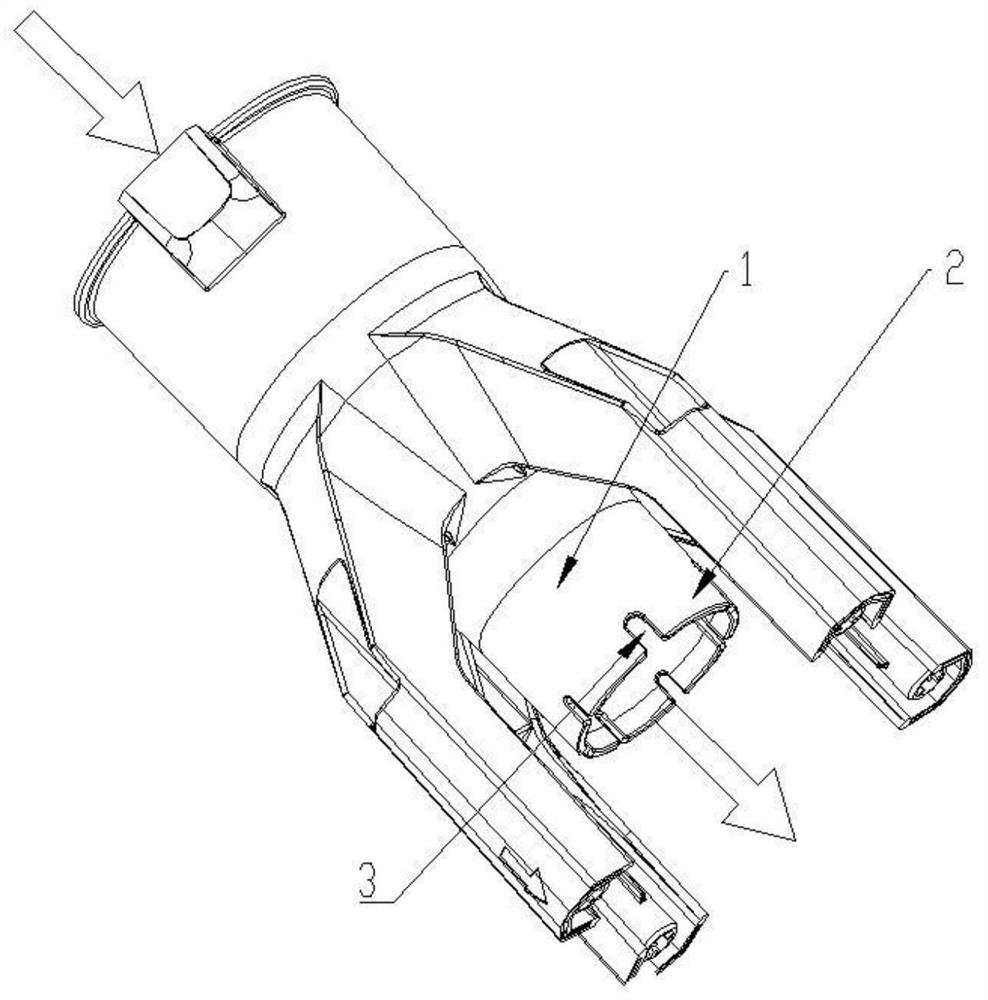

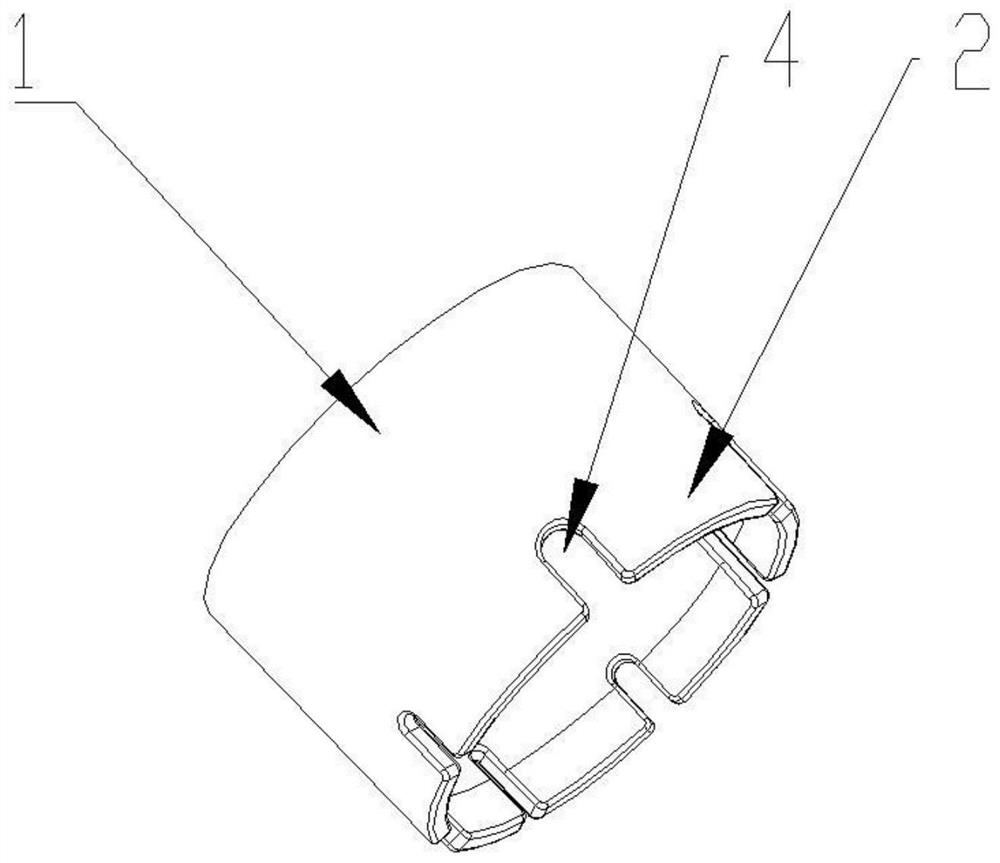

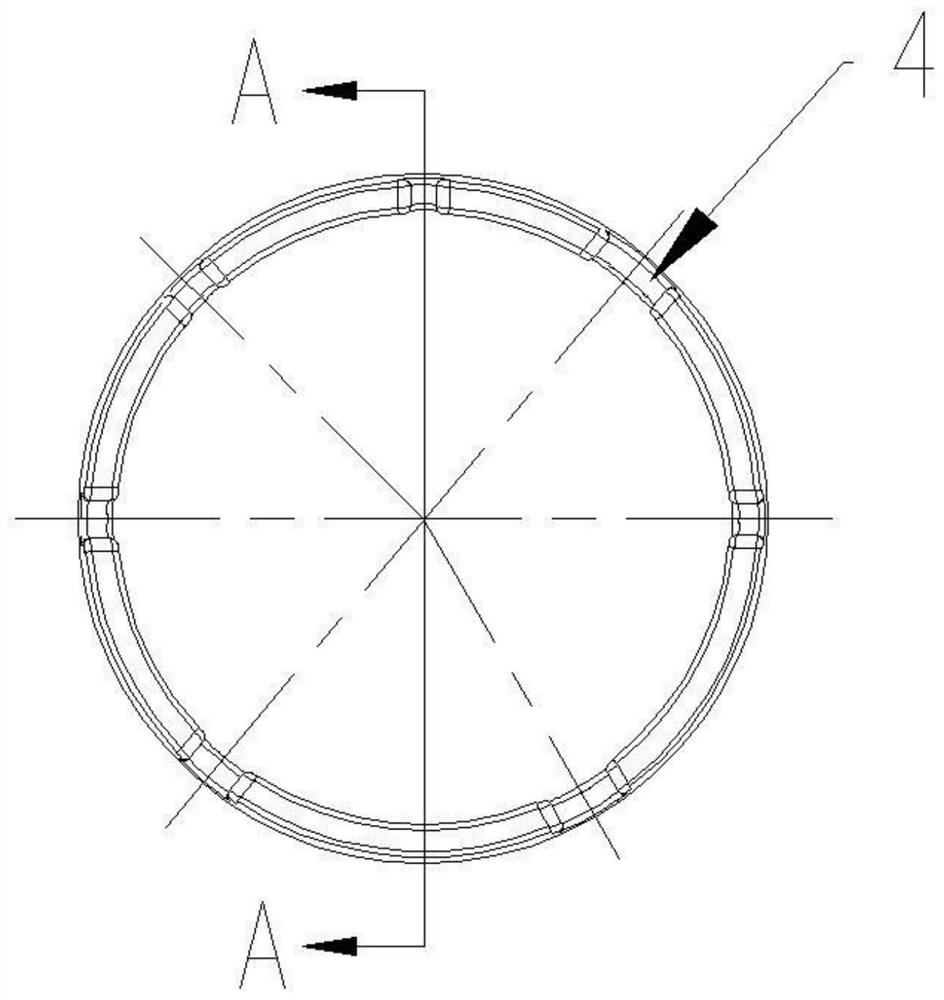

[0039] Such as Figure 2 to Figure 4 As shown, the concavo-convex body is a plurality of grooves 4, and at least one dimension of at least two grooves 4 in the guide part 3 is different from the previous year, and / or, the grooves of the guide part are unevenly distributed on the inner wall of the port pipe wall 2, and the grooves The dimensions of 4 include the radial groove depth, the axial groove length, and the circumferential groove width with reference to the main body of the air outlet pipe; the year-on-year difference in dimensions includes the following differences: the difference in radial groove depth; Figure 4 Shown are axial groove lengths that vary; as in image 3 Different circumferential groove widths are shown; as image 3 As shown, the grooves are unevenly distributed on the inner wall of the port pipe wall 2; more preferably, the circumferential distances between any two grooves in the guide part 3 are different.

[0040] It should be noted that the groove...

Embodiment 2

[0046] Such as Figure 5 to Figure 7 As shown, the concavo-convex body is a plurality of ribs 5, and at least one dimension of at least two ribs 5 in the guide portion is different from the previous year and / or the ribs of the guide portion are unevenly distributed on the inner wall of the port pipe wall 2, and the ribs The dimensions of ribs include radial rib depth, axial rib length, and circumferential rib width. The ribs 5 are protrusions arranged radially along the air outlet pipe, and the protrusions are used to divert and redirect the wind flow. The year-on-year difference in dimension size includes the following differences: difference in radial rib depth; Figure 7 Different axial rib lengths are shown; as Image 6 Different circumferential rib widths are shown; as Image 6 As shown, the ribs are unevenly distributed on the inner wall of the port pipe wall 2; more preferably, the circumferential distances between any two ribs in the guide portion 3 are different.

...

Embodiment 3

[0052] Such as Figure 8 to Figure 10 As shown, the concavo-convex bodies are at least two grooves 4 and at least two ribs 5, wherein the dimensions and distribution characteristics of the grooves refer to Embodiment 1, and the dimensions and distribution characteristics of the ribs refer to Embodiment 2, the difference is that the concavo-convex The body is unevenly distributed on the inner wall of the port pipe wall 2, that is, the uneven distribution defines grooves and ribs at the same time.

[0053] Similar to the foregoing, the number of grooves 4 and ribs 5 is any number not less than two. In particular, when the number of grooves 4 and ribs 5 is a prime number, such as 3, 5, 7, 11, 13, etc., the generation of resonance can be effectively avoided and the noise cancellation effect can be enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com