High-efficiency heat recovery unit for temperature wastewater

A technology of heat recovery and heat recovery devices, applied in heat pumps, refrigerators, refrigeration components, etc., can solve problems such as affecting the environment and wasting heat energy, and achieve the effects of improving utilization, facilitating operation, and alleviating energy shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

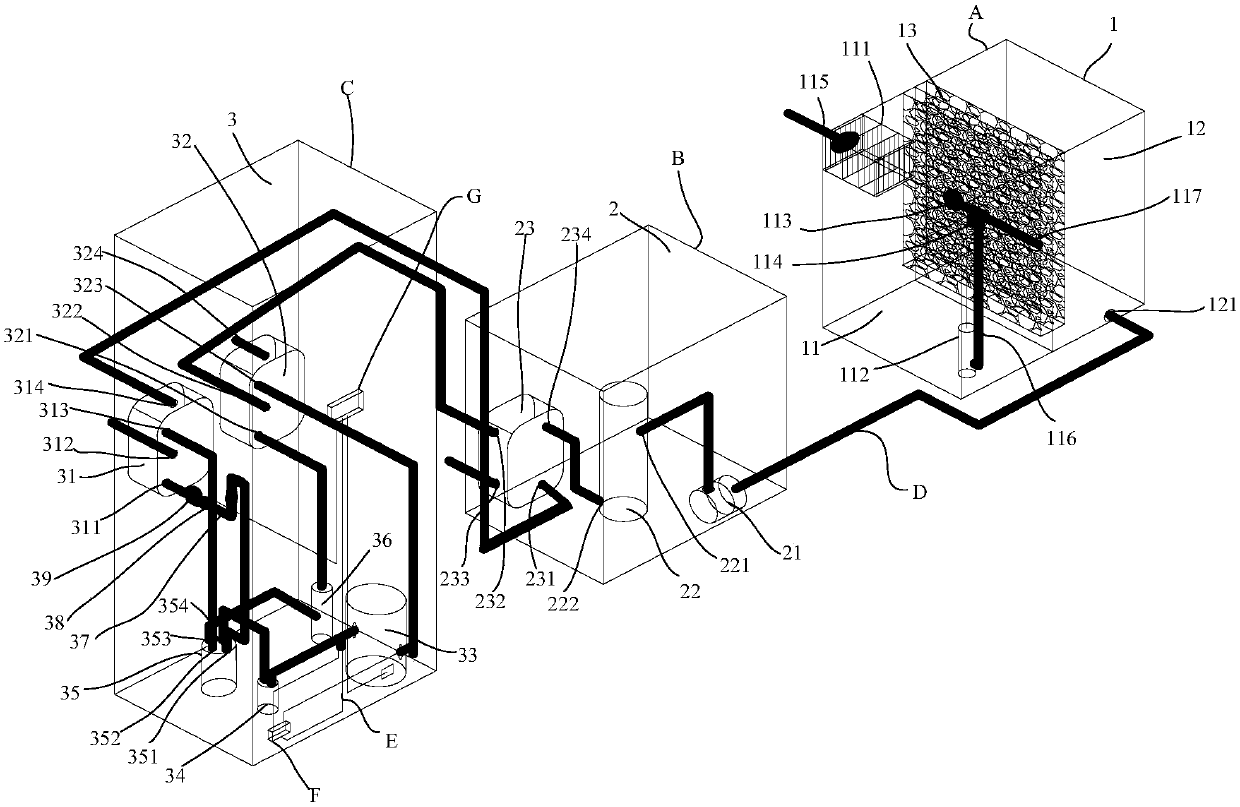

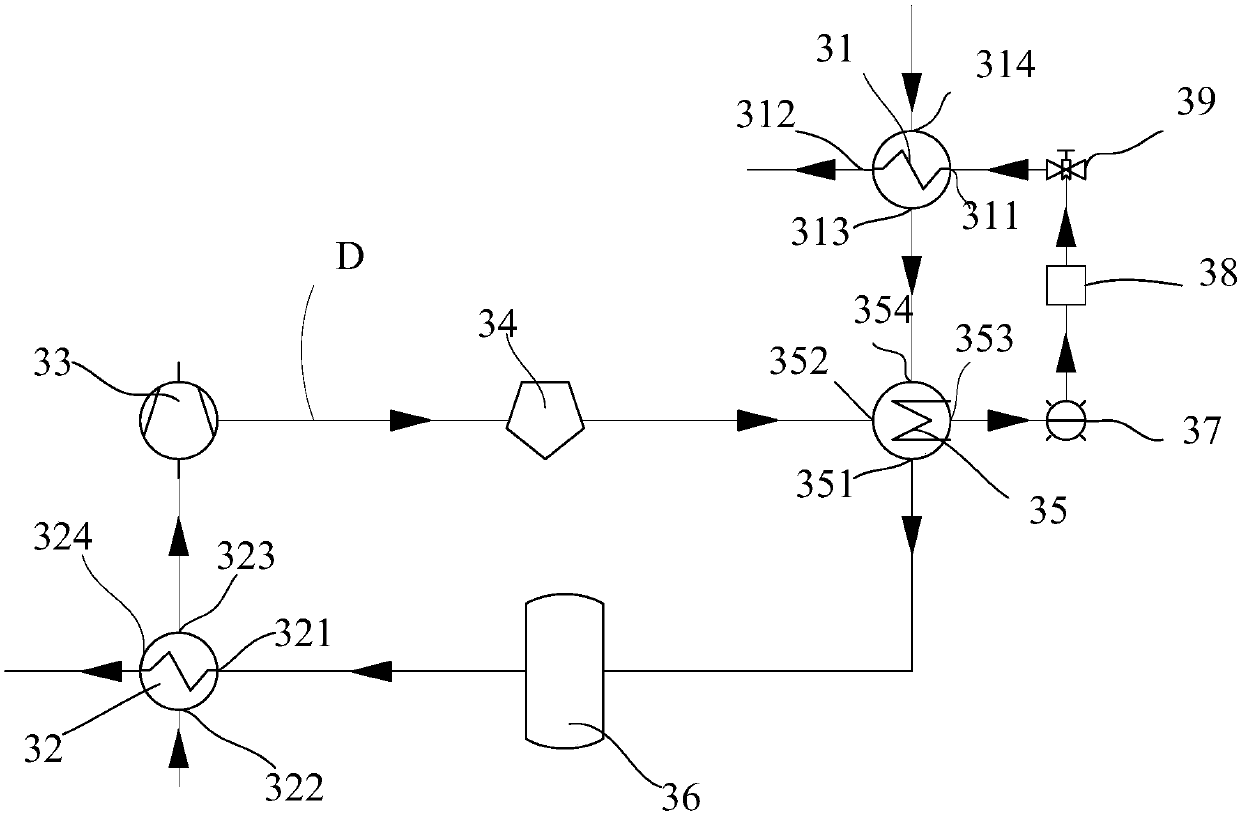

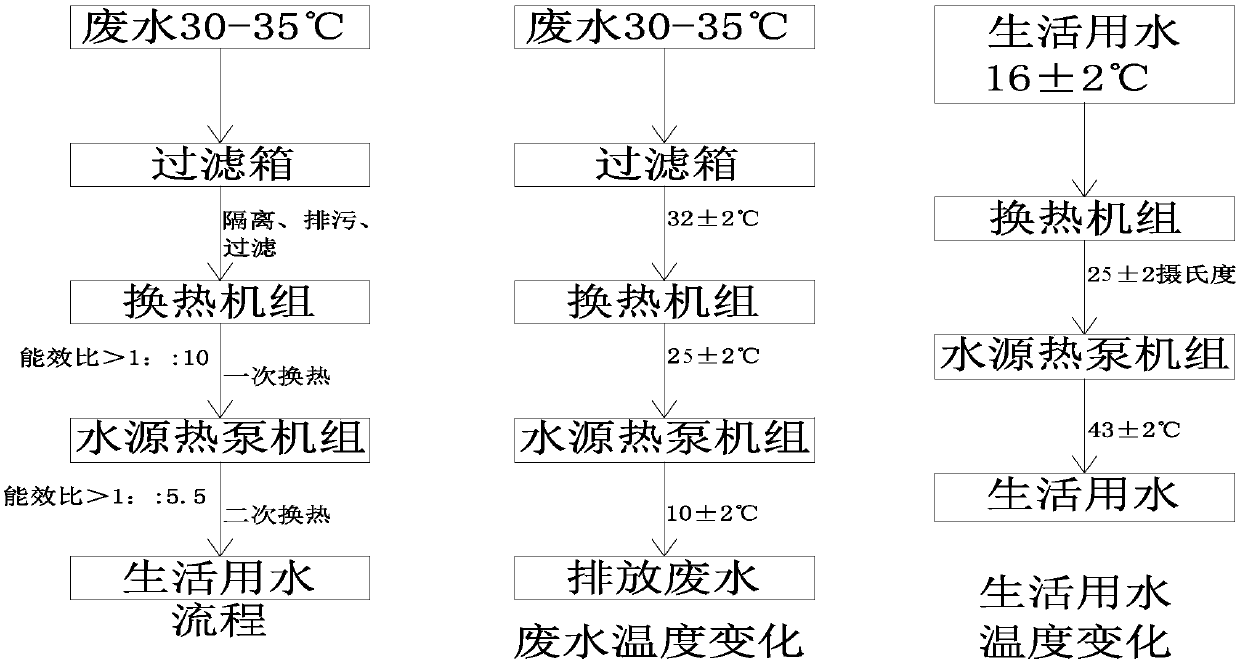

[0027] Example 1, such as figure 1 As shown, the present invention provides a high-efficiency heat recovery unit for temperature wastewater. The temperature wastewater is mainly a large amount of waste hot water discharged in the production process of industries such as dyeing and finishing, washing water, papermaking, chemical industry, and bathing. The temperature is generally between 30-90°C, so there is a large space for utilization, that is, the design of the present invention is mainly aimed at recycling the above-mentioned temperature wastewater. Its high-efficiency heat recovery unit includes wastewater treatment device A, primary heat recovery device B, and secondary heat recovery device C along the flow direction of temperature wastewater. Wastewater treatment device A mainly processes impurities in wastewater to increase the temperature. The working efficiency of the wastewater in the whole unit also plays a role in protecting the overall equipment. The setting of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com