Cylinder coaxiality automatic detection machine with controllable compacting force

A technology of coaxiality and pressing force, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of cumbersome detection, inconvenient analysis, heavy workload, etc., and achieve high accuracy of measurement data and small measurement error , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

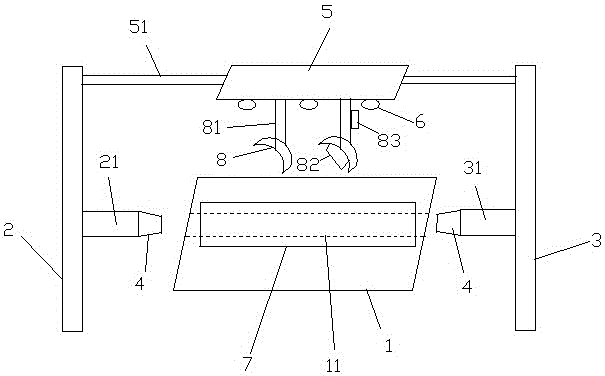

[0017] Such as figure 1 As shown, an automatic detection machine for cylinder coaxiality with controllable pressing force, which has a detection table 1, an arc-shaped reference groove 11, a left fixed column 2, a left telescopic cross bar 21, a right fixed column 3, a right Main technical features such as telescopic crossbar 31, plug gauge 4, reference plate 5, connecting rod 51, displacement sensor 6, cylinder barrel 7, arc-shaped pressure claw 8, lifting rod 81, pressure sensor 82 and lifting displacement sensor 83.

[0018] An automatic detection machine for cylinder coaxiality with controllable pressing force, including a detection table, a left fixed column, a right fixed column, two plug gauges, a reference plate, three displacement sensors, a PLC, and two arc-shaped pressing jaws , pressure sensor and lifting disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com