A sensor arrangement method for on-line monitoring of the health status of a ship lock miter door

A technology of health status and layout method, applied in the direction of measuring devices, instruments, etc., can solve the problems that manual detection cannot achieve real-time monitoring, missed detection of the deep position of the door body, and affects channel transportation, etc., to achieve convenient distributed installation and low error rate The effect of low, more optimized routing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

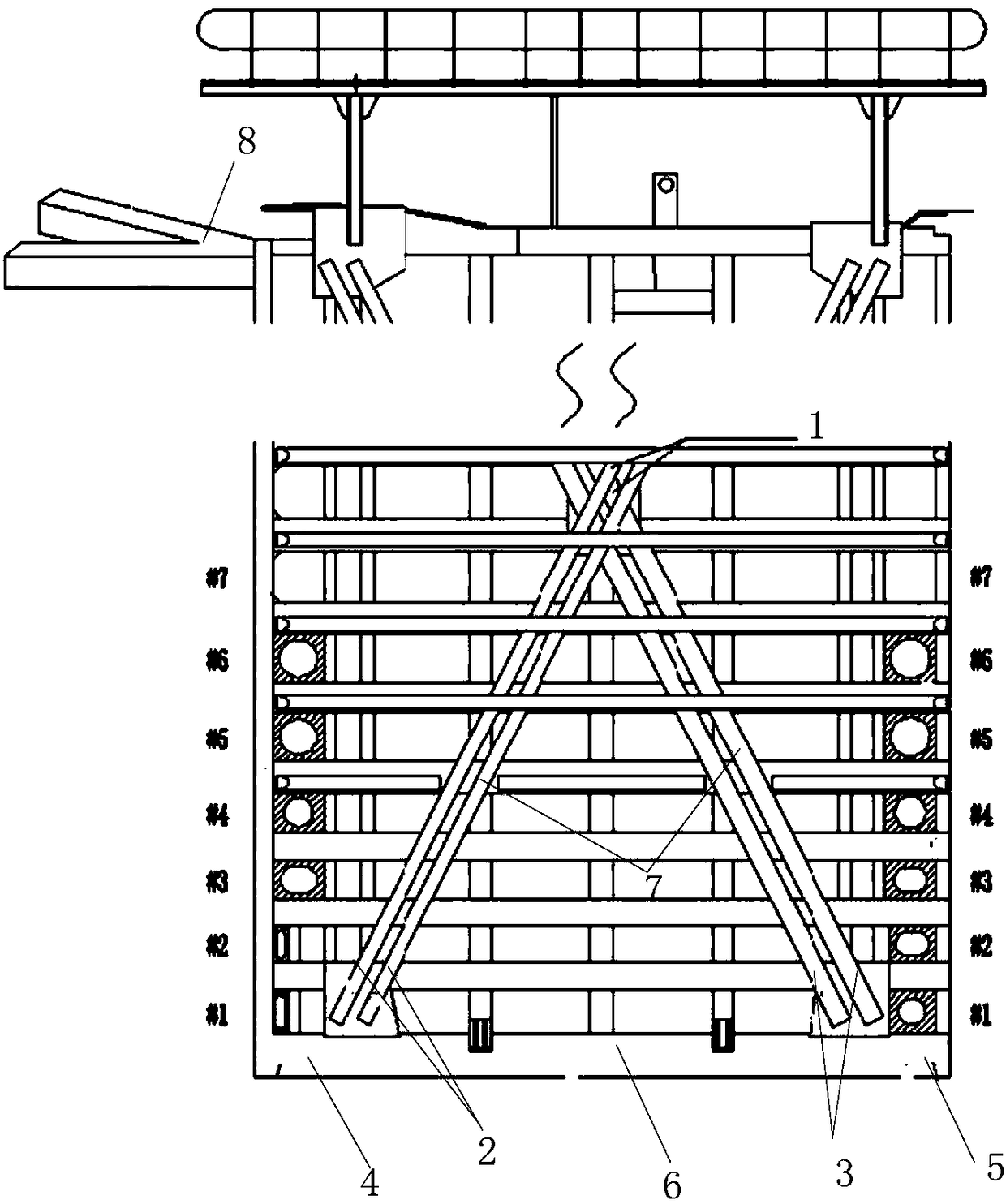

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: It should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

[0024] The basic idea of the present invention is to comprehensively utilize fiber optic grating strain sensors, fiber optic grating temperature sensors, fiber optic crack detection sensors, and fiber optic vibration sensors to form a sensor network through a reasonable and standardized layout, to carry out remote online monitoring of the ship lock, and to obtain real-time information on the miter gate of the ship lock. Health status information.

[0025] The concrete steps of this embodiment are as follows:

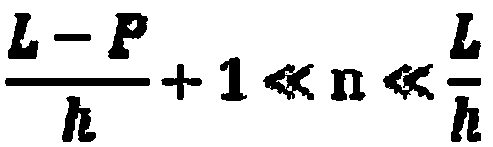

[0026] Such as figure 1 As shown, a sensor arrangement method for on-line monitoring of the health status of a ship lock miter gate includes the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com