Spring testing machine

A testing machine and frame technology, which is applied in the testing of mechanical components, testing of machine/structural components, and the use of stable tension/pressure to test the strength of materials. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

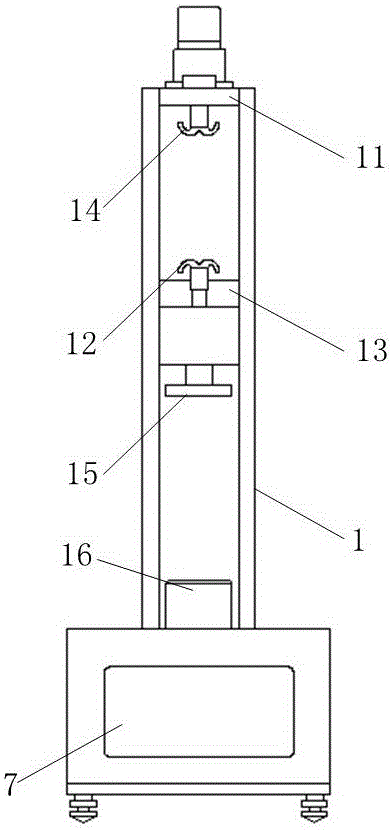

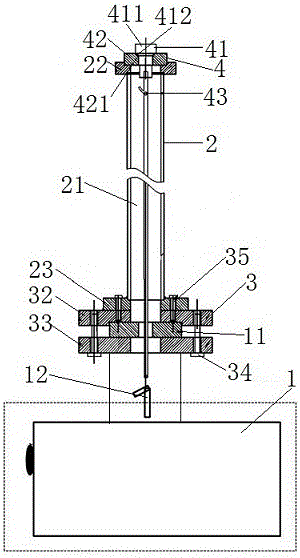

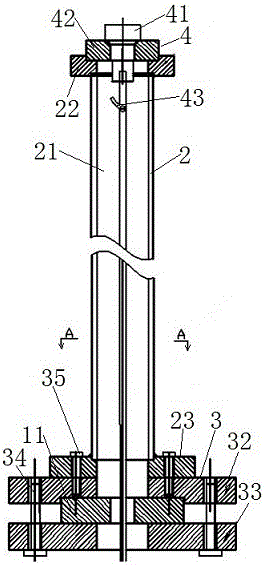

[0020] The specific embodiment of spring testing machine of the present invention, as Figure 2 to Figure 4 As shown, it includes a frame 1 and a stretching stroke expansion bracket 2 fixed on the upper side of the frame 1 through a fixing structure 3. The stretching stroke expansion bracket 2 includes a protective sleeve 21 with a hollow inner cavity, which is welded and fixed on the upper end of the protective sleeve 21. The cover plate 22 and the flange plate 23 welded and fixed on the lower end of the protective cover 21. The cover plate 22 is connected with the upper draw hook 43 for cooperating with the pull-down hook 12 on the frame to stretch the tested spring, and the spring hooked between the upper draw hook 43 and the pull-down hook 12 is in the protective cover 21 to avoid spring decoupling Fly out and hurt people. For avoiding the friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com