Airplane seat constraint system function and airtight testing bench

A technology of restraint system and aircraft seat, which is applied in the testing of mechanical components, testing of machine/structural components, liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problem of insufficient supply of winch tension, sensor force value decay, Low work efficiency and other problems, to achieve the effect of stable product function inspection, reasonable structural design, and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

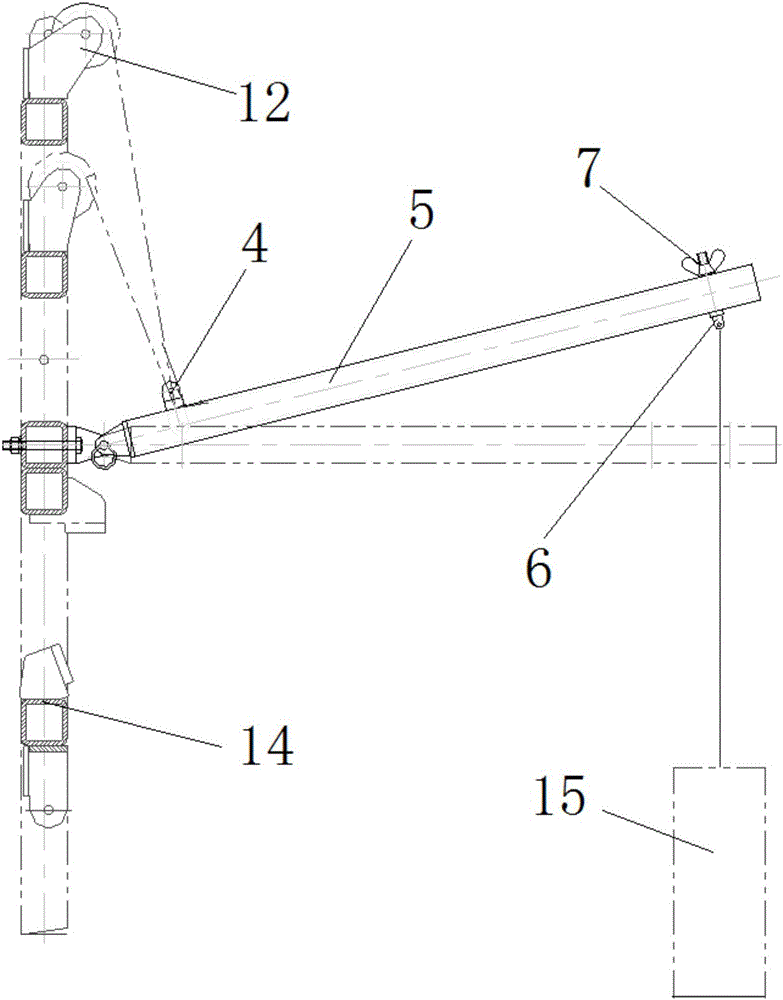

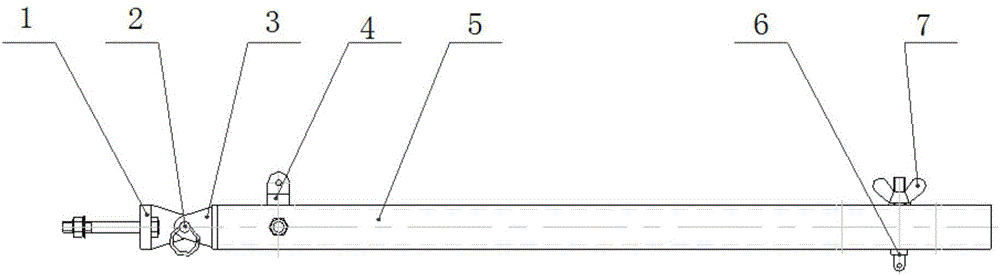

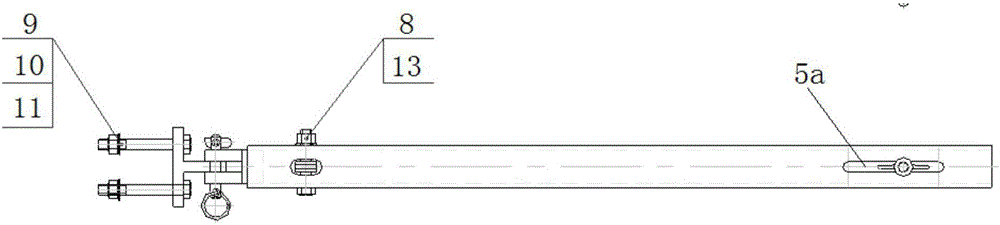

[0017] Such as Figure 1 to Figure 3 Shown, a kind of aircraft seat restraint system function and airtightness test bench, comprise hanging lug 4, hanging beam 5, boom 6, butterfly nut 7, fixed pulley 12, bracket 14, described fixed pulley 12 is fixed on the bracket 14, one end of the suspension beam 5 is hinged with the support 14 through the connecting assembly, the lifting lug 4 is installed on the suspension beam 5 near the upper end of the support 14, and the suspension rod 6 is located on the suspension beam 5 close to the support 14 One end of the suspension rod 6 is connected with the suspension beam 5 through a wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com