Numerical simulation method for coal mine abscission layer water periodical water inrush disaster

A numerical simulation and delamination technology, applied in CAD numerical modeling, electrical digital data processing, special data processing applications, etc., can solve problems such as less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

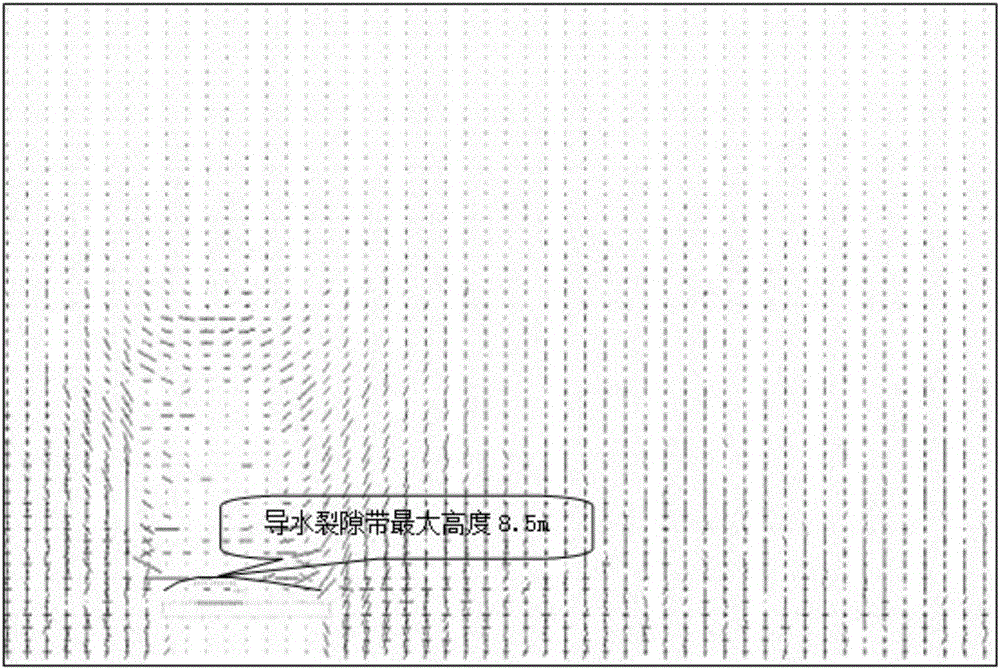

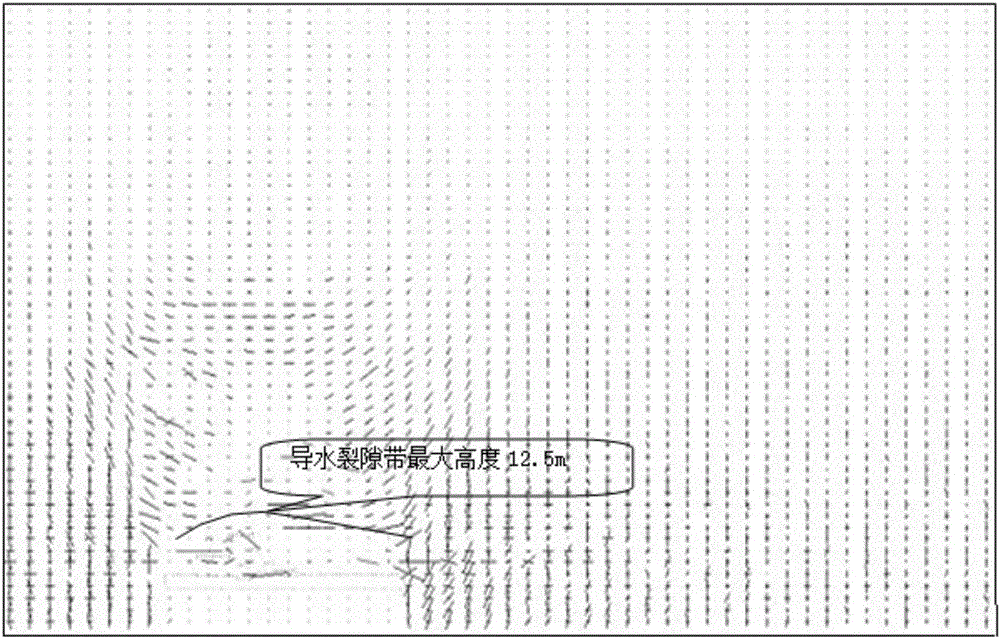

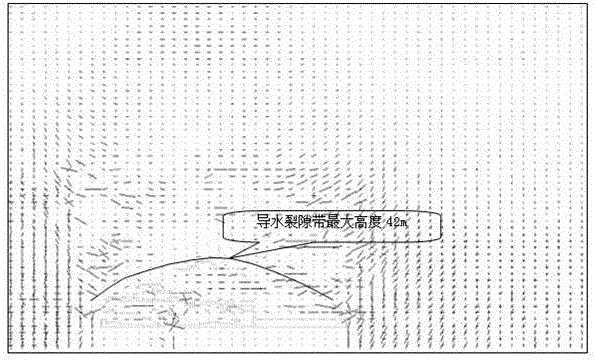

[0031] In the following examples, there are boreholes H1504, H1604 and H1704 within the scope of the fully mechanized mining face of coal mine 1121. Combined with the comprehensive column diagram of the mine, the H1604 borehole is used as the main hole to establish an experimental model. See Table 1 and Table 2. In this example, the seepage version of the real fracture process analysis system RFPA developed by Mechsoft Technology (Dalian) Co., Ltd. is used for numerical simulation. The method for discriminating the separation layer in the overburden of the main coal mining seam includes the following steps:

[0032] Several layers of rock strata with different lithology are formed into the combined key layer, which can be regarded as a single rock layer, and several single rock layers are combined to form several groups of composite plates. In each group of composite plates, the nth layer of rock layer Loading of the bottom layer 1 rock formation:

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com