Square nickel hydride battery

A technology for battery packs and nickel metal hydride, applied in the direction of nickel storage batteries, battery pack components, alkaline storage batteries, etc., can solve the problems of reducing the qualified rate, increasing the difficulty of production technology, increasing the internal resistance of single battery packs, etc., and achieving the reduction of internal resistance The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

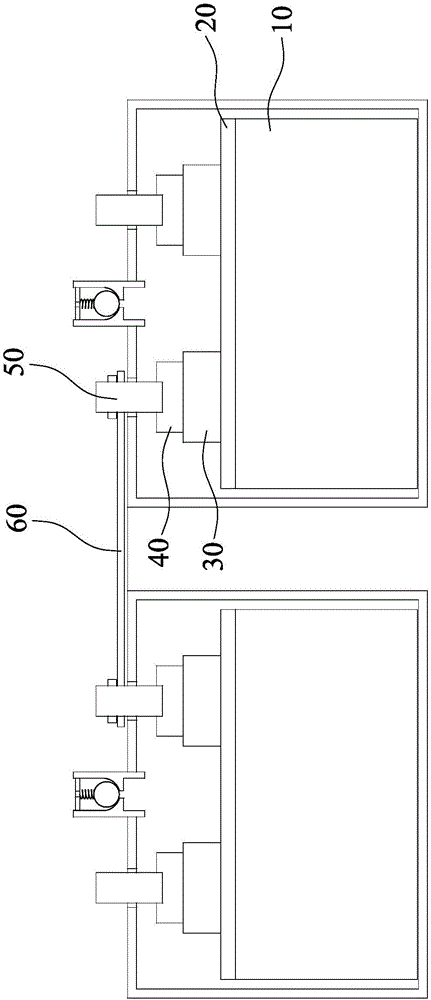

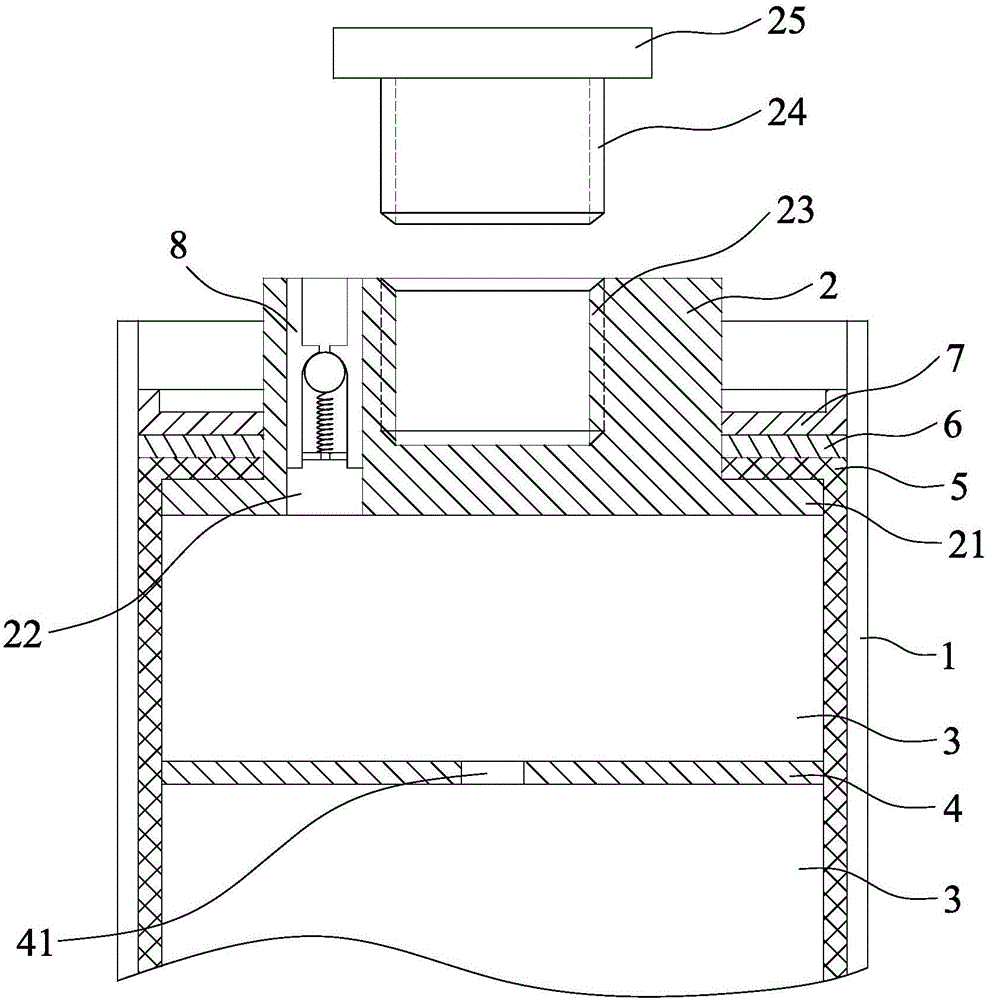

[0029] Such as figure 2 As shown, it is a square Ni-MH battery pack disclosed by the present invention, which includes a square case 1 , an electrode bus block 2 , a conductive plate 4 and more than two single cores 3 .

[0030] More than two single cell cores 3 are sequentially placed in the square housing 1, and two adjacent single cell cores 3 are separated by a conductive plate 4, and the conductive plate 4 is provided with a communication hole 41 to make each single cell core 3 communicate and share. electrolyte.

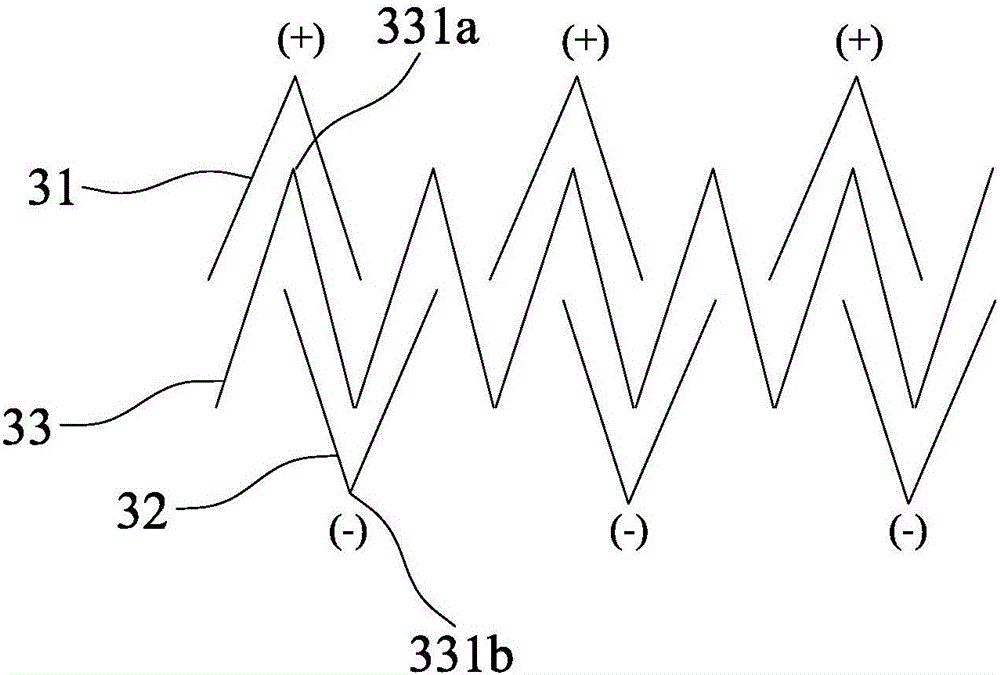

[0031] The single cell 3 includes a plurality of positive plates 31 , a plurality of negative plates 32 and a continuous folded separator 33 , the positive plates 31 and the negative plates 32 are respectively placed on both sides of the continuous folded separator 33 and completely separated....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com