An elevator

A technology for elevators and elevator cars, applied in the field of elevators, can solve problems such as frictional performance degradation, accidental sliding, and unexpected sliding of ropes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

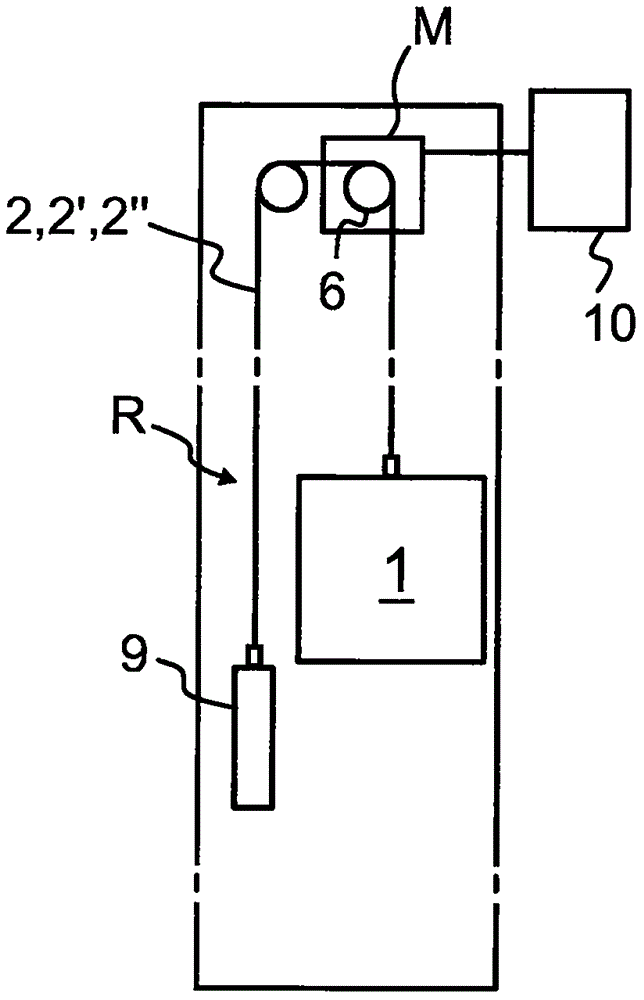

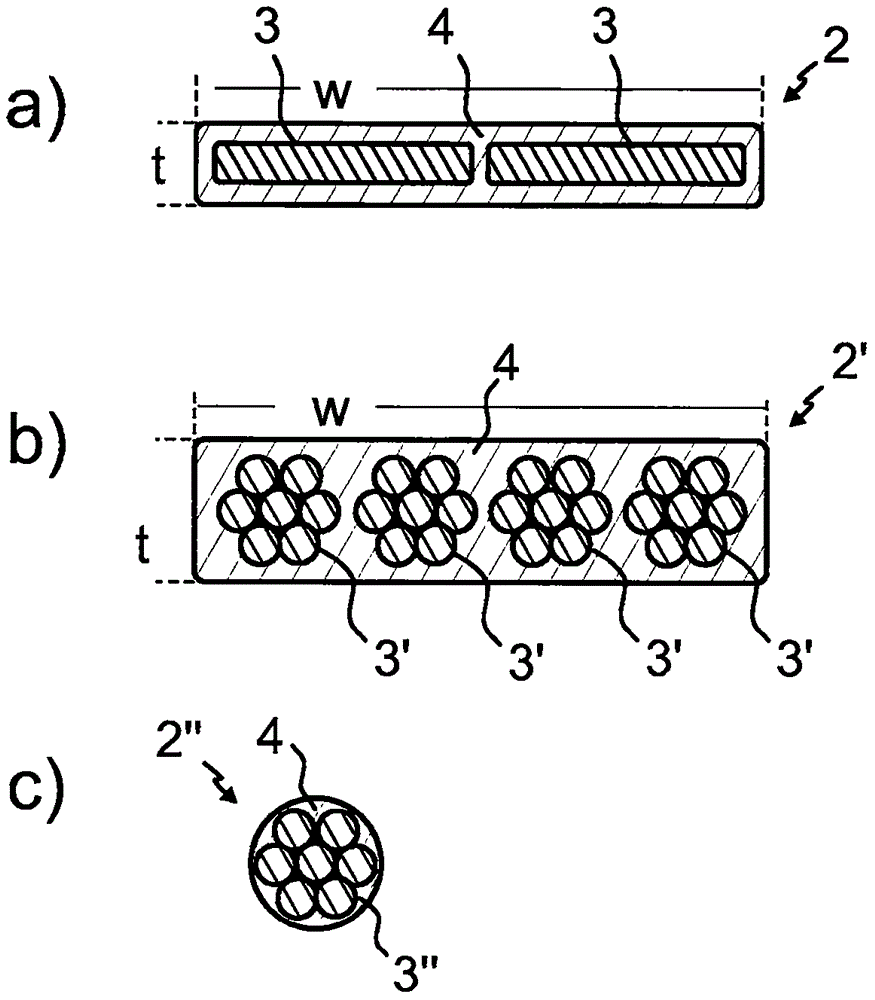

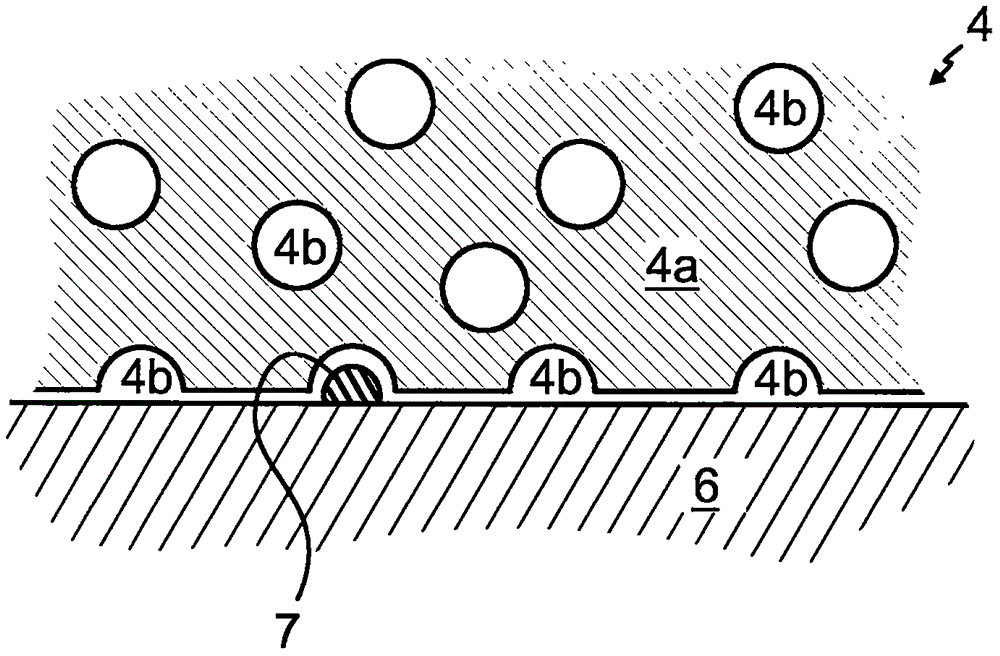

[0020] figure 1 A preferred embodiment of an elevator is shown comprising an elevator car 1 and suspension ropes R suspending the elevator car 1 with at least one suspension rope 2, 2', 2" connected to the elevator car 1 , preferably a plurality of suspension ropes 2, 2', 2". figure 2 Figures a to 2c show alternative cross-sections of individual ropes 2, 2', 2". Each of the above-mentioned at least one suspension rope 2, 2', 2" comprises an elastomeric coating 4 (i.e. A layer 4 of one or more load-bearing members 3 , 3 ′, 3 ″ in elastomer), the coating 4 forms the outer surface of the rope 2 , 2 ′, 2 ″. Each of said at least one suspension rope 2, 2', 2" is engaged with a rotatable traction member 6 via said outer surface formed by coating 4. Coating 4 is in contact with rotatable traction member 6, in particular its Traction surface contact. The properties of the joint between the rotatable traction member 6 and the rope 2 , 2 ′, 2 ″, in particular the specific firmness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com