A method of knitting a yarn-changing plated ring by knitting one side of the technical front on a flat knitting machine

A flat knitting machine and technology, applied in the directions of weft knitting, knitting, textiles and papermaking, can solve the problems of increasing production capacity, uncoordinated structure and appearance, and achieve the effects of increasing production capacity, saving man-hours and reducing weaving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

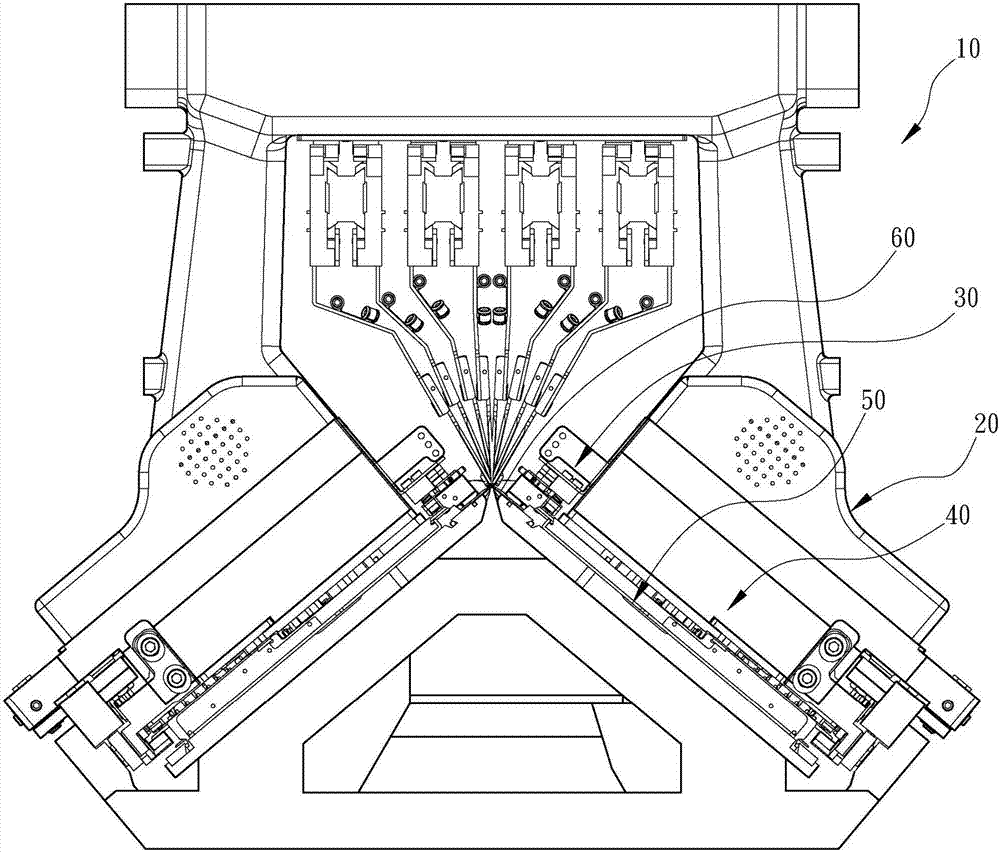

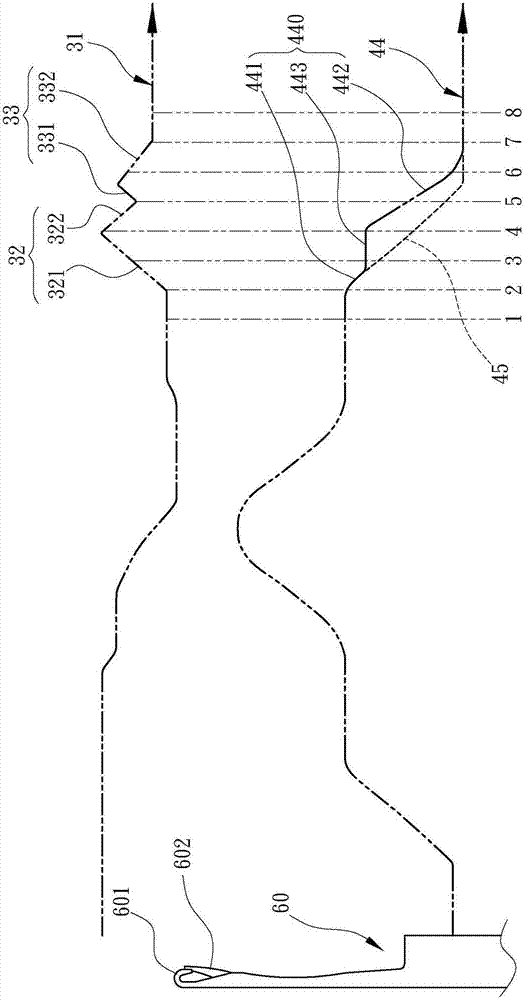

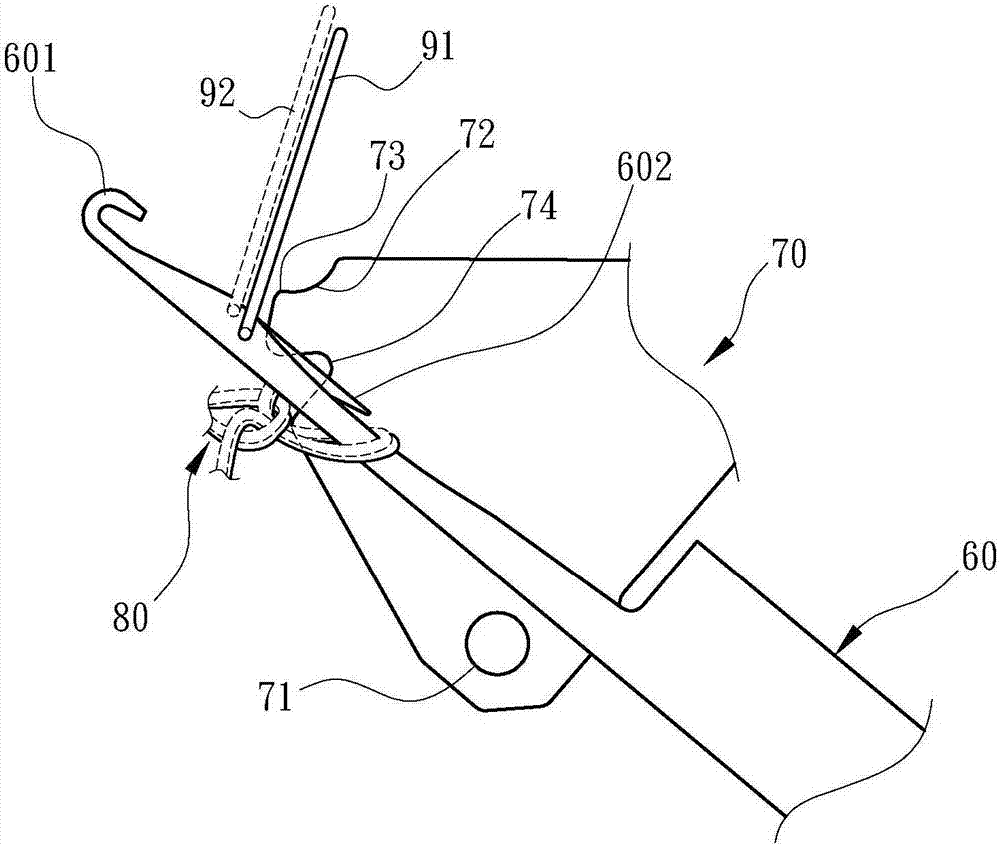

[0018] The preferred embodiment and detailed technical content of the method of knitting a yarn-changing plated ring on one side of the technical front of the flat knitting machine according to the present invention are described as follows with reference to the drawings. First, please also see Figure 1 ~ Figure 3 shown; among them, figure 1 It is a schematic plan view of a partial side view of a flat knitting machine in a preferred embodiment of the present invention; figure 2 It is a schematic partial plan view of the trajectory of the standard plated circle formed by the knitting needle and the letter of the present invention; image 3 for the invention figure 2 Partial schematic diagram of CITIC gram sheet and knitting needle moving at the first moment. As shown in the figure, it can be clearly seen that the flat bed knitting machine 10 (Flat Bed Knitting Machine) includes two needle beds 50 (Needle Bed) and a machine head 20 ( Carriage); wherein, the needle bed 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com