Method and apparatus for tobacco stem stagewise sheeting by microwave expansion

A technology of microwave expansion and stem pressing, which is applied in the directions of tobacco, tobacco processing, application, etc., can solve the problem of limiting the utilization ratio and scope of tobacco stem utilization ratio and cut stem raw materials, limiting the use ratio and scope of microwave expanded cut cut stems, and affecting microwave expansion. Tobacco stem utilization and other issues, to achieve good toughness, maintain toughness, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

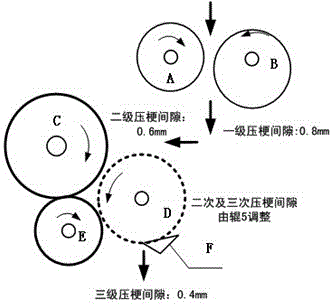

[0019] The expanded tobacco stems (expansion degree 380%) after microwave expansion are subjected to first-level stem pressing. After the stalk pressing, three-stage stalk pressing is carried out. After three step-by-step stalk pressing, stalks with a thickness of 0.2mm are produced; the stem foam collection device equipped on the first-level, second- and third-level stalk-pressing devices F, collect the stalk foam produced during the stalk pressing process.

Embodiment 2

[0021] The expanded tobacco stems (expansion degree: 280%) that have been expanded by microwaves are subjected to first-stage compression, the thickness of the stem after compression is 0.9mm, and then the second-level compression is performed, and the thickness of the stem is 0.65mm. After the second-stage stalk pressing, carry out the third-stage stalk-pressing, and after three steps of step-by-step stalk-pressing, the stalks with a thickness of 0.4mm are produced; The collecting device F is used to collect the stem foam generated in the process of pressing the stem.

Embodiment 3

[0023] The expanded tobacco stems (expansion degree: 150%) that have been expanded by microwaves are subjected to first-stage pressing, the thickness of the stem slices is 1 mm, and then the second-stage pressing is performed, and the thickness of the stem slices is 0.7 mm. After the second-stage stalk pressing, carry out the third-stage stalk-pressing, and after three steps of step-by-step stalk-pressing, a stalk with a thickness of 0.4mm is produced; Device F is used to collect the stem foam generated during the stem pressing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com