Annular filtering device for dibutyltin oxide production

A technology of dibutyltin oxide and filtration device, which is applied in filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of inconvenient operation, few suction filtration points, long solid-liquid separation time, etc. The effect of preventing filter clogging and rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

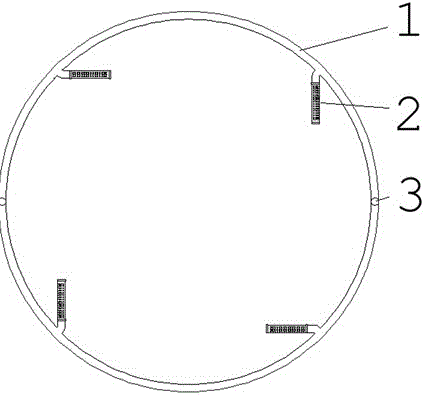

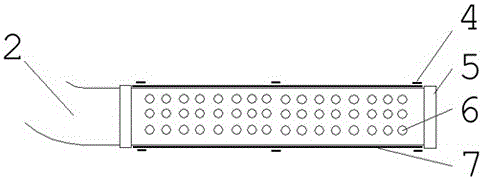

[0011] Such as figure 1 As shown, a ring-shaped filter device for the production of dibutyl tin oxide includes a ring pipe 1, a plurality of suction filter heads 2 connected to the ring pipe, and a water outlet 3 arranged on the ring pipe. The water outlet 3 and the vacuum The container pipes are connected, and the connection angle of the suction filter head 2 is 45° along the stirring direction of the container and the tangent to the loop pipe. The loop pipe 1 and the suction filter head 2 are made of metal with anti-acid and alkali corrosion or surface anti-corrosion treatment Of metal. The suction filter head 2 is provided with a filter screen 7, the filter screen 7 is evenly distributed with water-permeable holes 6, the two ends of the suction filter head 2 are connected with protruding rings 5, and the filter screen 7 is fastened by a compact material 4. The filter screen 7 is a stainless steel filter screen or a synthetic fiber filter cloth.

[0012] The working mode of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com