Two-dimensional layered ternary nano-composite photocatalyst, and preparation method and application thereof

A nanocomposite, two-dimensional layered technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problem of low hydrogen production efficiency in water decomposition, accelerate the transfer of interface charges, and improve catalytic efficiency , Improve the effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention provides a method for preparing a two-dimensional layered ternary nanocomposite photocatalyst, comprising the following steps:

[0037] S1. Calcining melamine in a muffle furnace to obtain g-C 3 N 4 ;

[0038] S2, put g-C 3 N 4 Grind into powder, add to deionized water, ultrasonically disperse into g-C 3 N 4 suspension;

[0039] S3, to g-C 3 N 4 Add nickel nitrate hexahydrate and cobalt nitrate hexahydrate into the suspension. After stirring for the first time, ammonia water is added dropwise, and then transferred to an autoclave for hydrothermal reaction. After treatment, the two-dimensional layered ternary nanocomposite photocatalyst Co (OH) 2 / g -C 3 N 4 / Ni(OH) 2 .

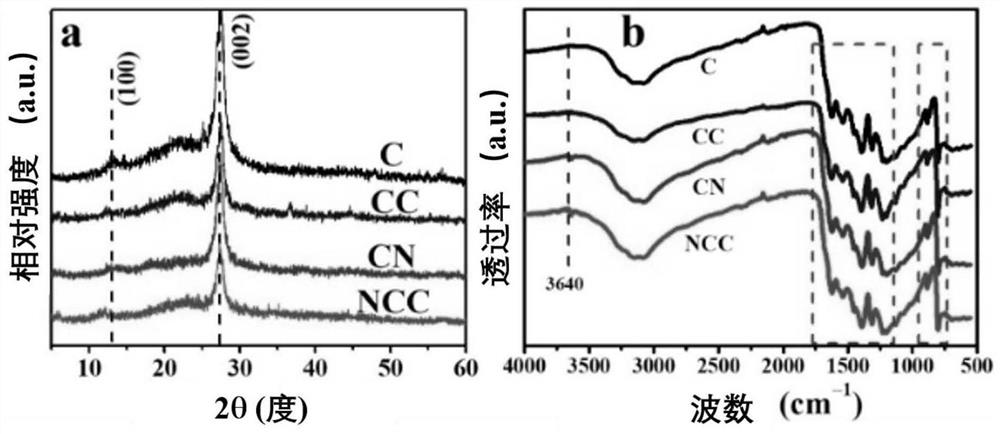

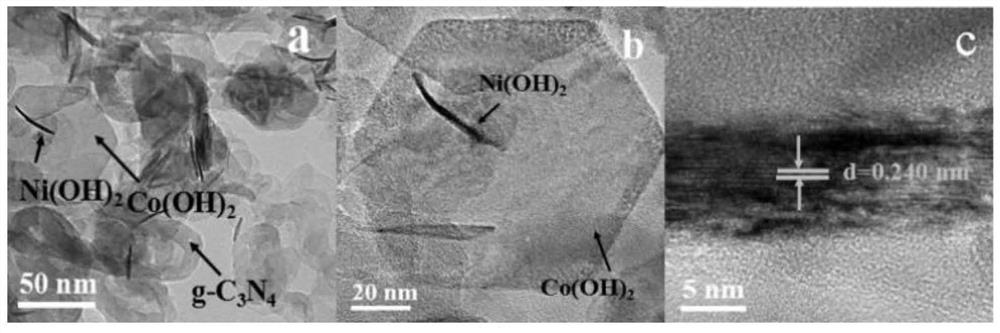

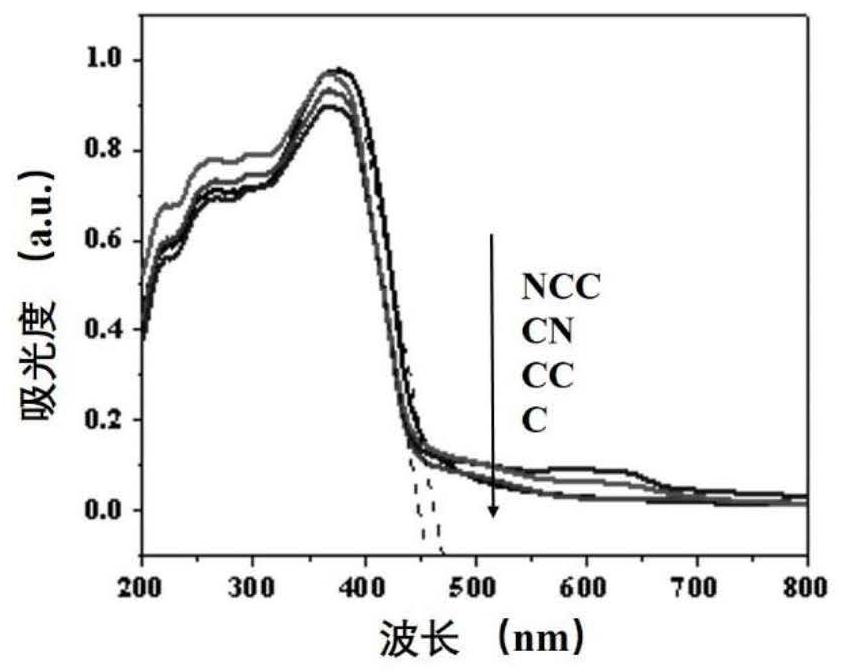

[0040] The present invention reacts in a Teflon-lined autoclave through a hydrothermal-precipitation technique, using layered Co(OH) 2 and Ni(OH) 2 Nanosheets to modify sheet-like g-C 3 N 4 , to prepare two-dimensional layered ternary nanocomposit...

Embodiment 1

[0051] This embodiment provides a method for preparing a two-dimensional layered ternary nanocomposite photocatalyst, comprising the following steps:

[0052] 1) Preparation of g-C 3 N 4 Nanosheets: put melamine in a muffle furnace, the temperature program of the muffle furnace is 5°C / min, the calcination time is 2h, the calcination temperature is 550°C, the reaction is carried out under nitrogen atmosphere, and it is taken out after cooling to room temperature. Grinding agate body to obtain pure phase g-C 3 N 4 Nanosheets;

[0053] 2) Add 1g of g-C 3 N 4 Disperse the powder in water and ultrasonically treat it for 30 minutes to obtain a uniformly dispersed suspension;

[0054] 3) Add 0.094g cobalt nitrate hexahydrate and 0.095g nickel nitrate hexahydrate to the suspension, stir at room temperature for 6 hours, add 1.2mL of 25wt% ammonia water dropwise, then transfer the mixed solution into a 100mL autoclave, After heat-precipitation reaction for 3 h, the collected prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com