Bending machine used for machining metal integral type sound barrier

A sound barrier and integral technology, applied in the field of bending machines, can solve the problems of many processes, prone to technical failures, easy to rust, cracking, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

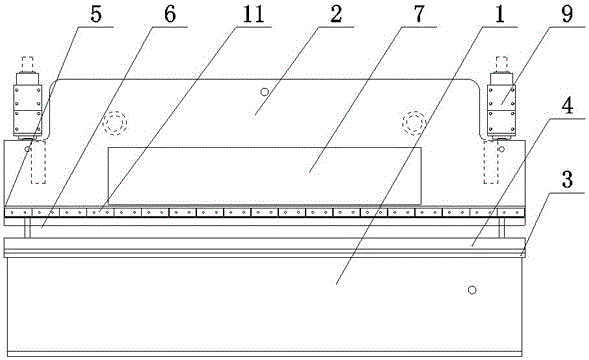

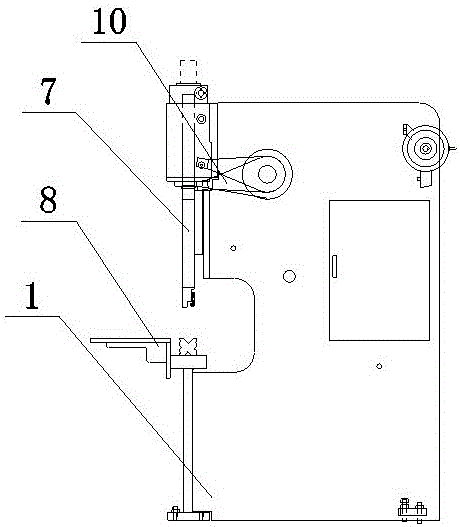

[0014] Such as figure 1 , figure 2 As shown, the bending machine used in the present invention for processing metal integral sound barriers includes a machine base 1 and a bending plate 2, the bending plate 2 is movably arranged on the machine base 1, and the upper end of the machine base 1 is set There is a lower mold base 3, the lower mold base 3 is provided with a lower mold 4, the lower end of the bending plate 2 is provided with an upper mold base 5, and an upper mold 6 is arranged on the upper mold base 5. The upper mold 6 and the lower mold 4 are arranged opposite to each other, and are used for bending and pressing the metal sound barrier frame. The bending plate 2 is provided with a long hole 7 for piercing in the transverse direction, and the long hole 7 for piercing the metal sound barrier. The barrier frame is folded from one side of the bent plate 2 to the other to ensure that the metal sound barrier frame is integrally formed into a seamless frame.

[0015] Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com