Circular barrel type double-cam charging and conveying mechanism for screw

A transmission mechanism, double cam technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of low screw sticking probability, and achieve the effect of reducing screw sticking, reducing failure rate, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below with reference to accompanying drawing and in conjunction with embodiment, describe the present invention in detail:

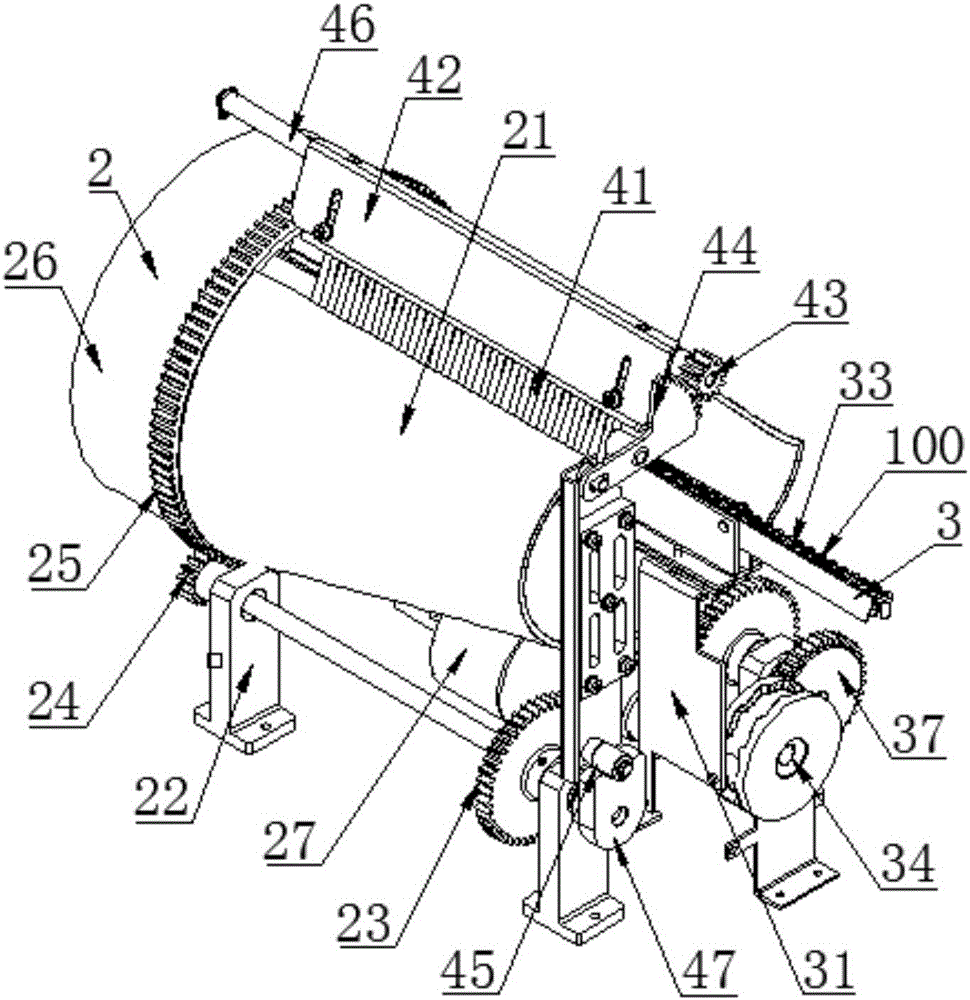

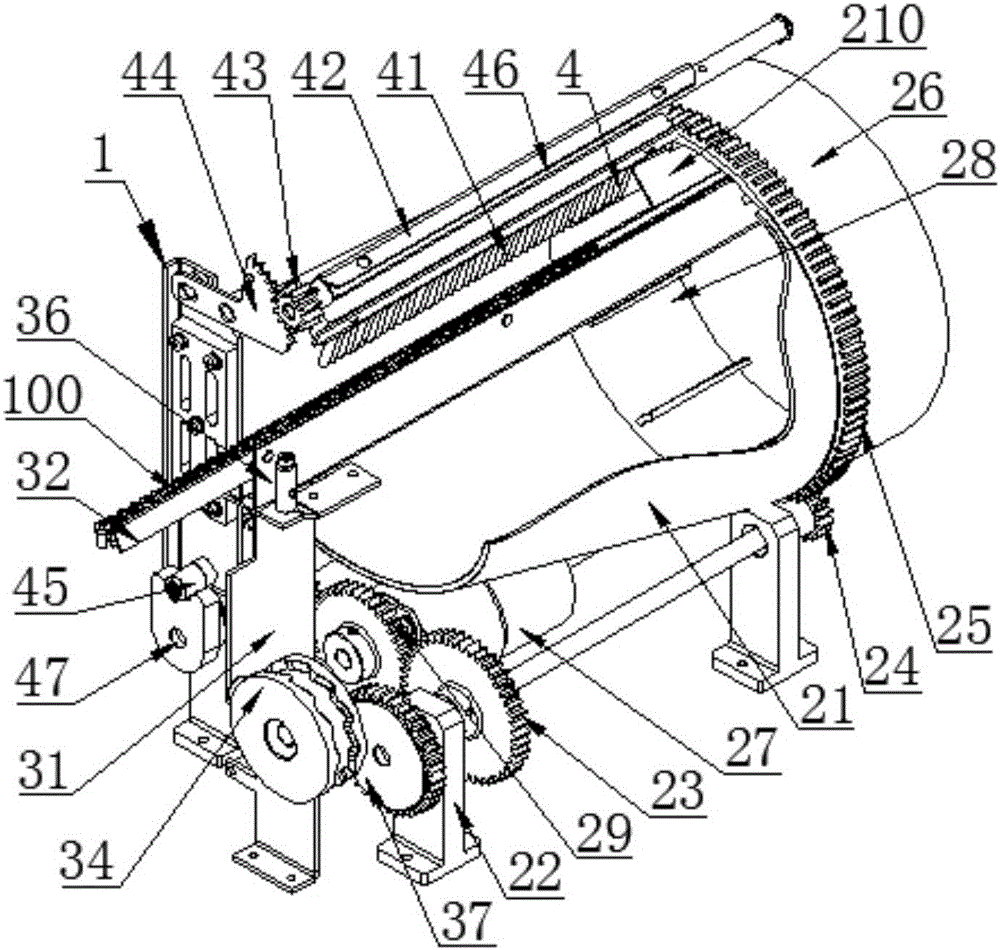

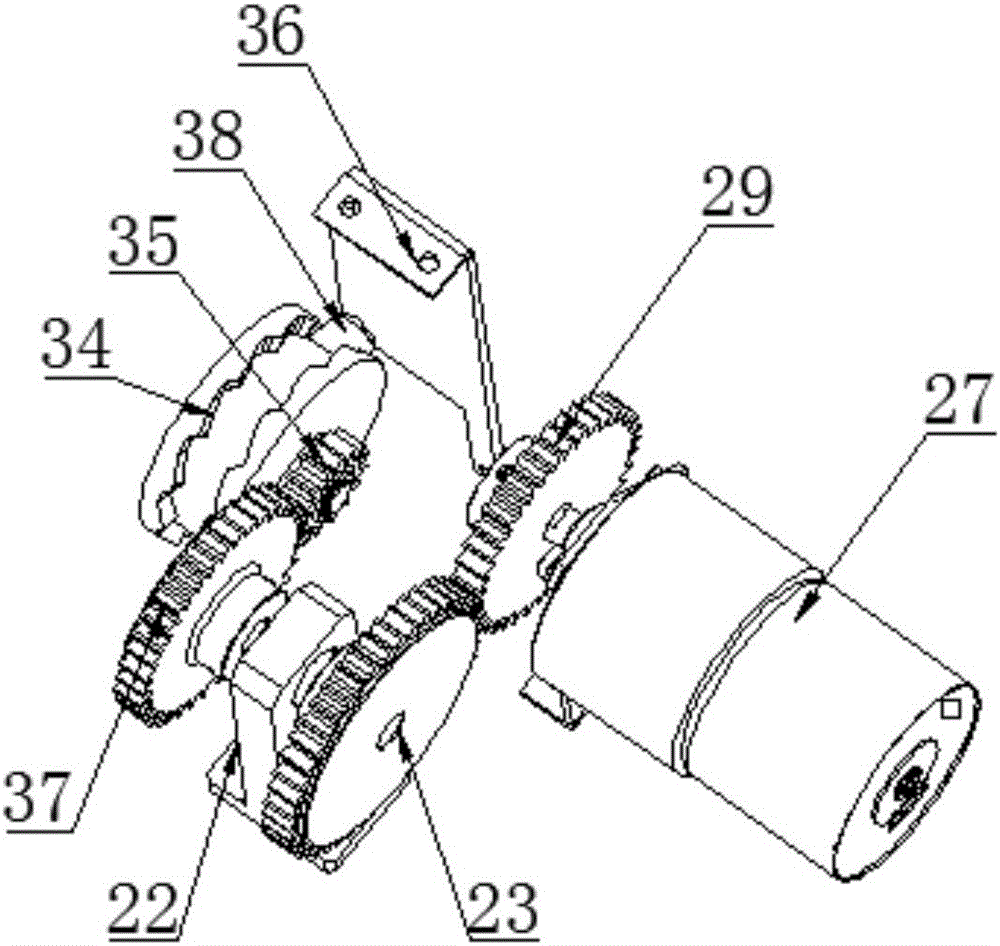

[0039] Such as Figure 1-Figure 7 Shown is an embodiment of the present invention. The cylindrical double cam screw feeding transmission mechanism provided by this embodiment includes a frame 1, a feeding mechanism 2, a feeding mechanism 3 and a sweeping mechanism 4. Figure 1-7 Let’s describe each constituent mechanism in detail, and the drawings of each description simplify some components in order to see the internal structure and details more intuitively.

[0040] Such as Figure 1-Figure 2 As shown, wherein the feeding mechanism 2 includes a rotating cylinder 26 that sends the screw 100 to the feeding mechanism 3, and the rotating cylinder 26 is connected horizontally with the screw bin 21 equipped with the screw 100, from figure 2 It can be seen that the screw bin 21 of this embodiment is a fallen round table, the center of the upper bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com