Glass positioning device for glass edge grinding machine

A positioning device and edge grinding machine technology, applied in machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc. and other problems, to achieve the effect of reducing human differences, enhancing the scope of use, and improving the verticality and parallelism of the glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

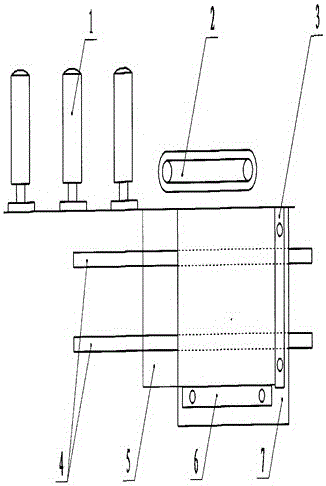

[0008] The present invention includes setting a vertical curved plate along the input guide belt, and setting a linear guide rail 4 on the vertical curved plate with the same height, parallel and inclination angle as the glass clamping conveying device, and the glass support plate 7 passes through the linear guide rail arranged on the linear guide rail. The sliding seat is installed on the linear guide rail, and a vertical positioning plate 3 and a parallel positioning plate 6 are arranged on the glass support plate.

[0009] When fixing the vertical positioning plate and the parallel positioning plate, the method of testing the glass sample can be adopted: while grinding, the glass is inspected at the same time, and the positions of the vertical positioning plate and the parallel positioning plate can be adjusted at any time. When grinding glass, the glass is manually positioned against the vertical positioning plate and the parallel positioning plate to position the glass.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com