Support element for absorbing forces in a vehicle

A support and force absorption technology, applied in vehicle components, vehicle safety arrangements, superstructure sub-assemblies, etc., can solve the problems of reducing the strength of the support, increasing the weight of the vehicle, and high installation costs, saving space, avoiding The effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

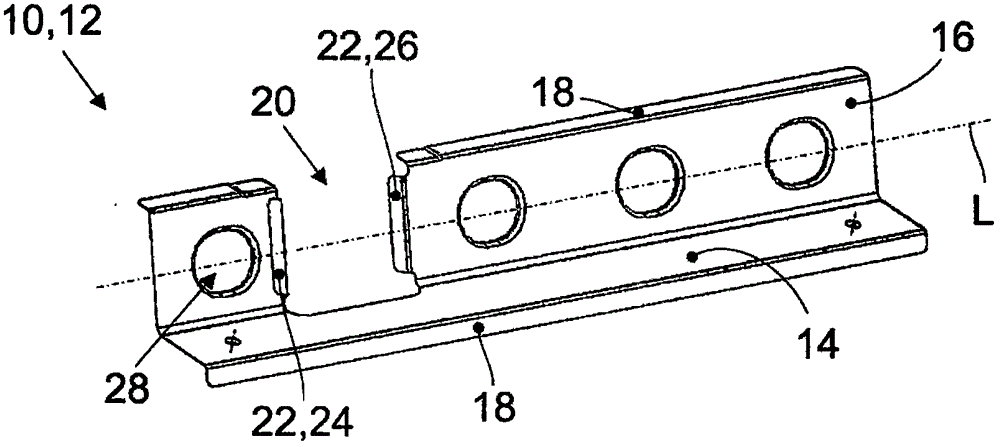

[0041] figure 1 The first profile part 10 of the support part 12 according to the invention is shown in a cutaway form, wherein the first profile part 10 extends along the longitudinal axis L and is designed approximately L-shaped. The first profile part 10 is in figure 1 A lower plane 14 and a rear plane 16 are formed in the schematic diagram of the drawing, which have folded-over end sides 18 at their free ends.

[0042] The first profile part 10 comprises an opening 20 which, in the schematic illustration, lies mainly on the rear plane 16 and has a rectangular shape. The opening 20 is delimited by a delimiting surface 22 , in this case extending along a longitudinal axis L of a first delimiting surface 24 and a first, second delimiting surface 26 , which are formed by the folded edges of the first profile part 10 . However, the delimiting surface 22 can also be formed by the wall of the support part 12 itself. The opening 20 opens towards the folded-over end side 18 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com