Double vector propeller rotor/fixed wing compound vertical take-off and landing aircraft

A vector propulsion, vertical take-off and landing technology, applied to vertical take-off and landing aircraft, aircraft, rotorcraft, etc., can solve the problems of low overall structural rigidity, large rotor span, and easy flutter, etc., to achieve high safety and comfort High performance, high operating capacity, and large operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

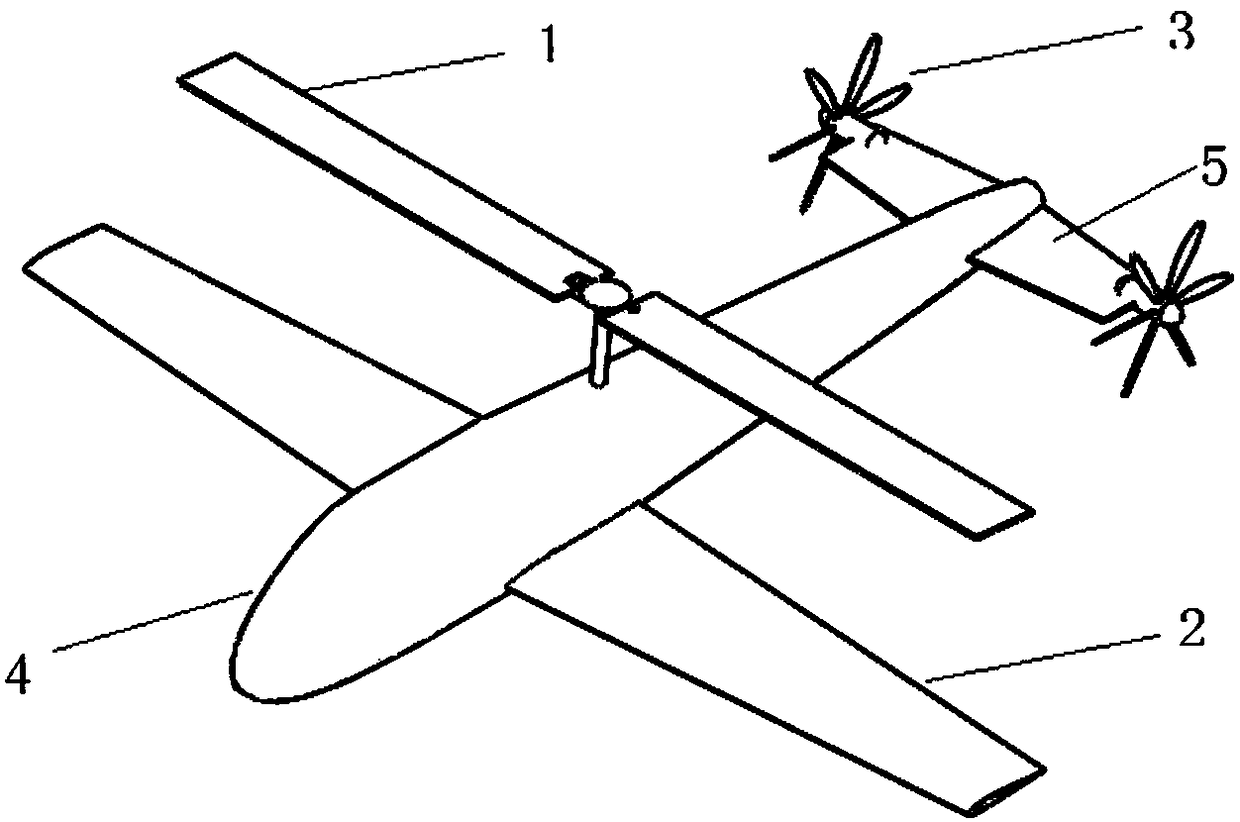

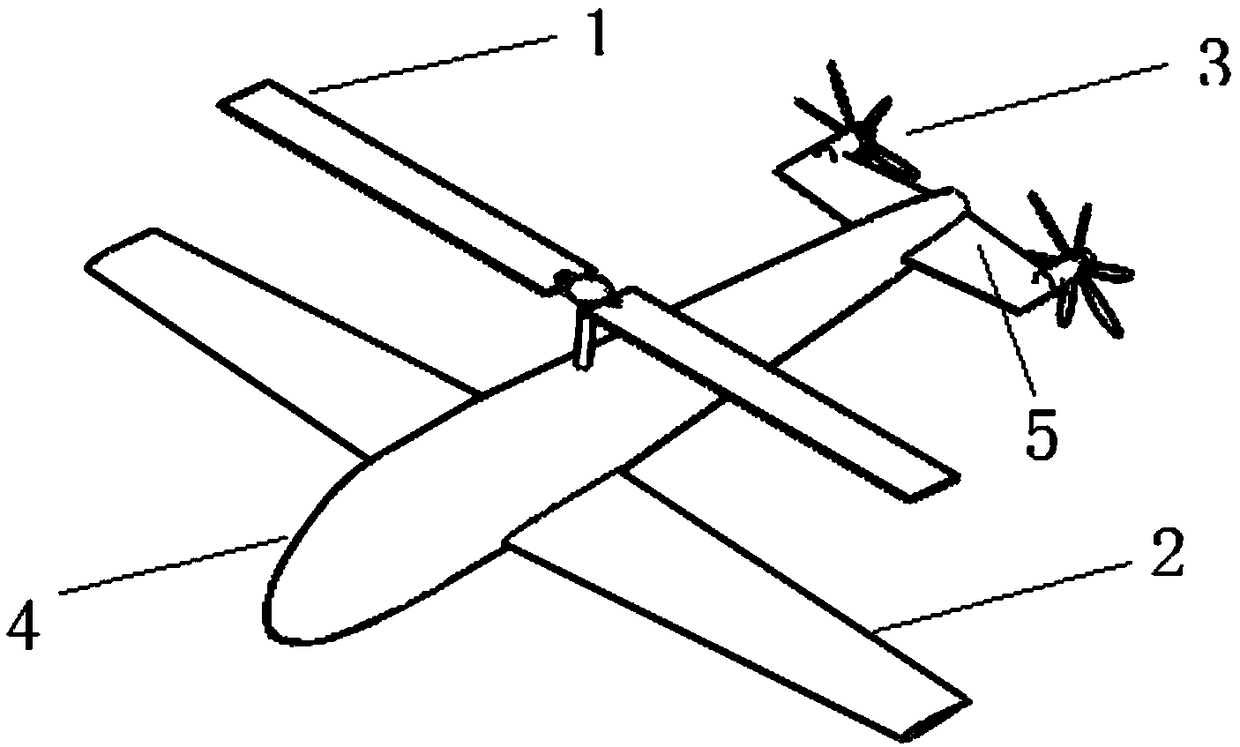

[0020] The present invention provides a kind of dual-vector propeller rotor / fixed-wing composite vertical take-off and landing aircraft, such as figure 1 As shown, the aircraft includes a special rotor 1, a wing 2, a vector propeller 3, a fuselage 4 and an empennage 5. Described special type rotor 1 is positioned at the top of fuselage 4 about 40% length from front to back, and the planar shape of its blade is isosceles trapezoidal, and blade length and average width ratio are 6-10, compared with conventional helicopter rotor blade (long The width ratio is 15-20) wider, the root-to-tip ratio is about 0.6, and the front and rear symmetrical airfoils with a relative thickness of 8%-12% and upper and lower curves are elliptic curves are selected. The joint between the wing 2 and the fuselage 4 is located below the fuselage, the geometric center of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com