steel support structure

A technology for supporting structures and steel structures, applied in pillars, building structures, buildings, etc., can solve the problems of inability to set up platforms, inconsistent appearance, inability to set beams, etc., and achieve simple structure, neat and uniform appearance, and enhanced bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

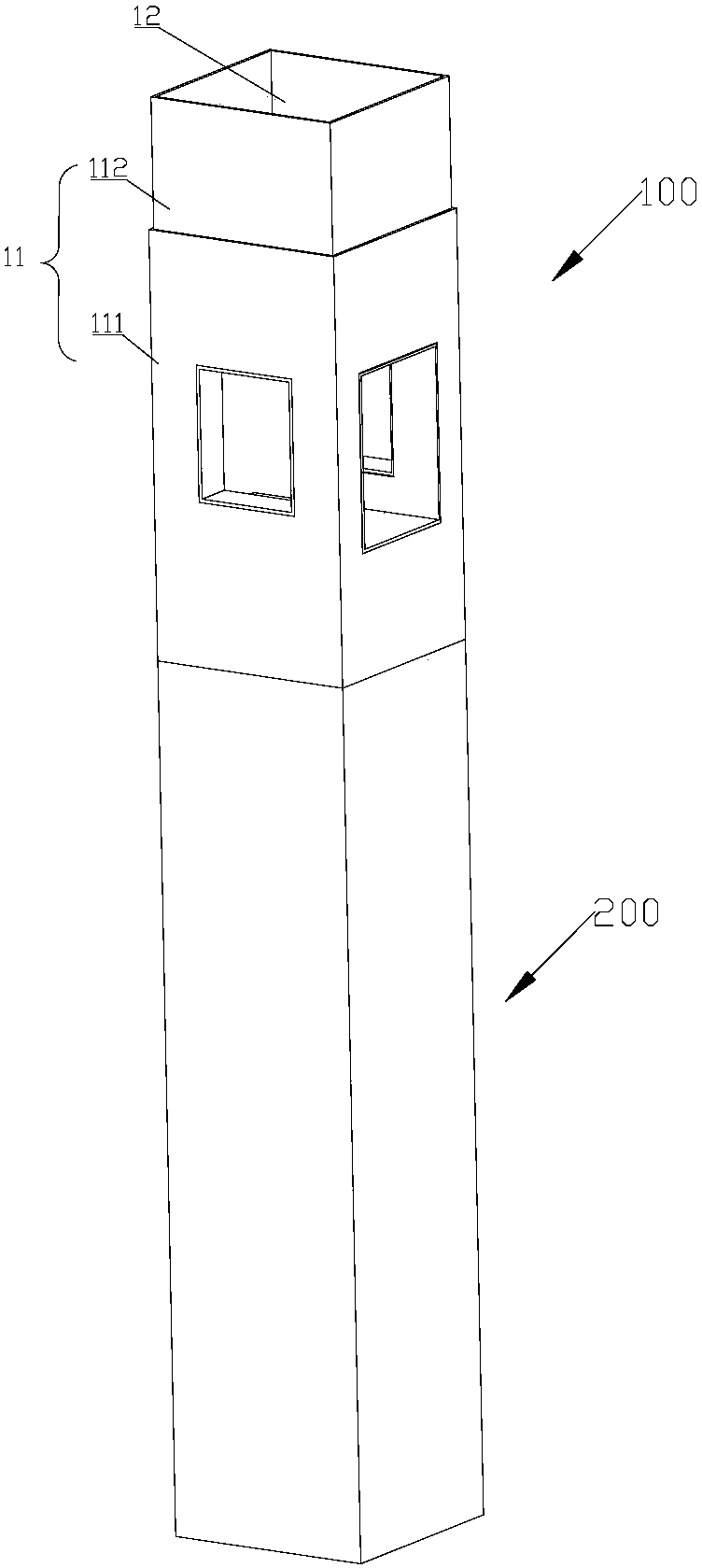

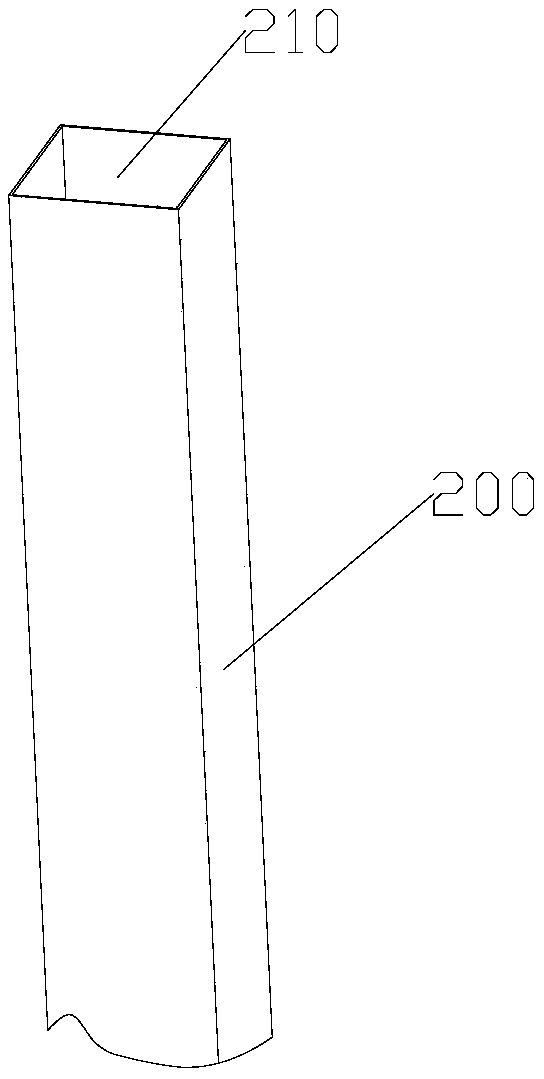

[0057] Such as figure 1 , figure 2 As shown, the steel structure supporting structure includes a column 200 and a corbel structure 100 . The post 200 is a tubular structure that includes a post lumen 210 .

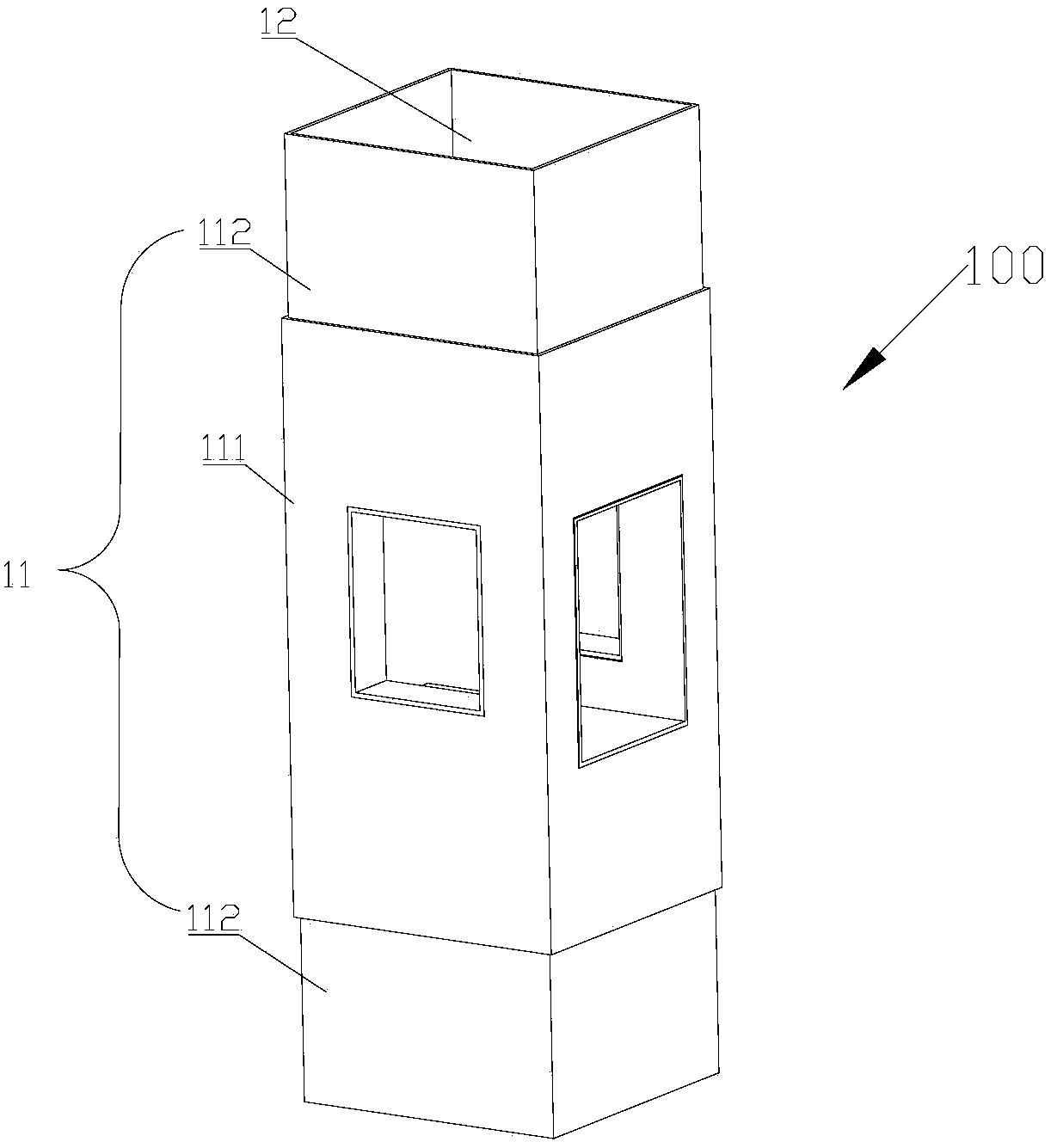

[0058] Such as image 3 , Figure 4 , Figure 5 with Image 6 As shown, a steel structure corbel 100 includes a sleeve 10 and a connecting piece 20 . The cannula 10 has a cannula wall 11 which encloses a cannula lumen 12 . The tube wall of the sleeve includes a sleeve body 111 and an insertion tube 112 . Two ends of the sleeve main body 111 are respectively provided with a plug-in tube 112 . The insertion tube 112 and the casing main body 111 are integrally structured. The external dimensions of the socket tube 112 are smaller than the sleeve main body 111 . The insertion tube 112 is inserted into the column lumen 210 . The outer wall of the casing main body 111 is aligned with the outer wall of the column 200 . The sleeve tube wall 11 is provided with a first...

Embodiment 2

[0067] Such as Figure 8 As shown, the corbel structure in this embodiment is different from that in Embodiment 1. The corbel structure 100 includes a casing 10 and a connecting piece 20 . Sleeve 10 structure such as image 3 shown. The casing 10 has a casing wall 11, the casing wall 11 encloses a casing lumen 12, and the casing wall 11 is provided with a first through hole 13 penetrating through the casing wall 11 . The shape of the casing wall 11 and the shape of the casing lumen 12 can be quadrangular or circular, and can also be selected as other shapes according to actual needs. The quadrilateral can be a rectangle, a square or other available shapes. In the example shown, the cannula wall 11 is rectangular and the cannula lumen 12 is also rectangular. The position and number of the first through holes 13 can be selected according to actual needs. In this embodiment, four first through holes 13 are respectively opened on four surfaces of the rectangular casing wall...

Embodiment 3

[0074] Figure 11 The internal structure of the sleeve lumen in this embodiment is shown. The difference between this embodiment and Embodiment 1 is that the structure of the corbel is different. Such as Figure 11 As shown, the steel structure corbel includes a casing 10 and a connecting piece 20 . Sleeve 10 structure such as figure 1 shown. The cannula 10 has a cannula wall 11 which encloses a cannula lumen 12 . The sleeve tube wall 11 is provided with a first through hole 13 penetrating through the sleeve tube wall 11 . The shape of the casing wall 11 and the shape of the casing lumen 12 can be quadrangular or circular, and can also be selected as other shapes according to actual needs. The quadrilateral can be a rectangle, a square or other available shapes. In the example shown, the cannula wall 11 is rectangular and the cannula lumen 12 is also rectangular. The position and number of the first through holes 13 can be selected according to actual needs. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com