Turbo-rocket combined ramjet engine and operating method thereof

A technology of ramjet engine and working method, which is applied in the direction of combined engine, ramjet engine, mechanical equipment, etc., and can solve the problems of slow acceleration, large flow rate of high-thrust rocket, low specific impulse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

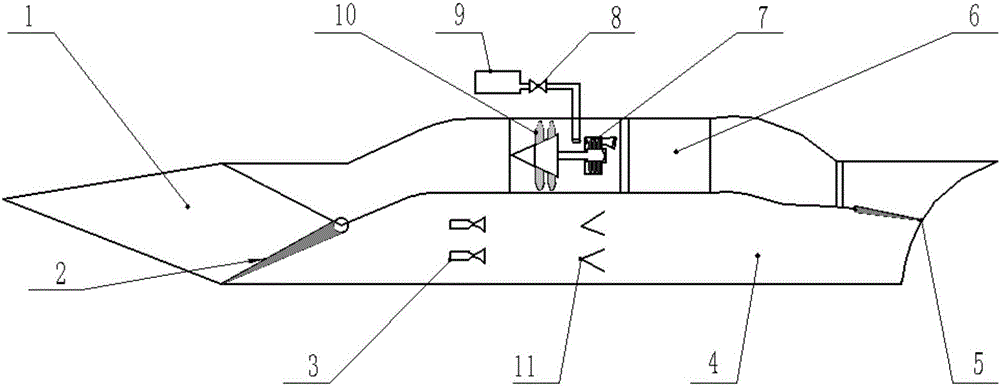

[0021] The invention provides a turbo-rocket combined ramjet engine, such as figure 1 As shown, the air turbine ramjet engine and the rocket basic cycle combination engine including the common inlet 1 and the common exhaust nozzle 5 can reduce air resistance by sharing the inlet 1 and the exhaust nozzle 5 .

[0022] The duct of the air intake 1 is provided with an air intake guide 2, and the air intake guide 2 is used to turn and close the inlet of the rocket basic cycle combined engine when the air turbo ramjet starts at a low speed, so that the air intake 1 communicates with the interior of the air turbo ramjet; it is also used to divert and seal the inlet of the air turbo ramjet when the speed of the air turbo ramjet is greater than or equal to Mach 2, so as to communicate the inlet 1 with the interior of the rocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com