Drying machine for crop seeds

A crop and dryer technology, applied in the agricultural field, can solve the problems of poor seed drying effect, high labor intensity and low work efficiency, and achieves the advantages of reducing drying time, reducing labor intensity and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

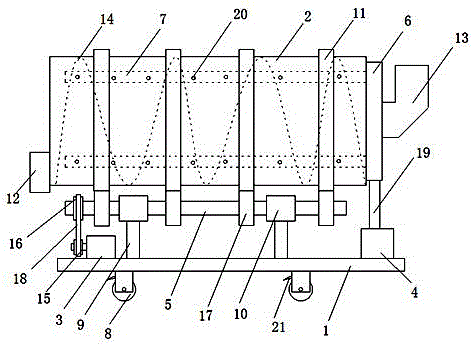

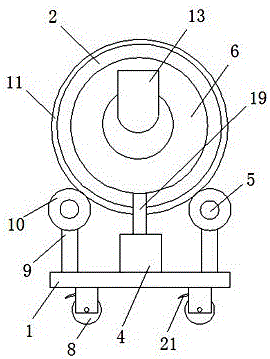

[0012] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0013] as attached figure 1 with 2 As shown, a dryer for crop seeds includes a bottom plate 1, a drying bin 2, a motor 3, a blower 4, a rotating shaft 5, a heater 6, an air duct 7 and a walking wheel 8, and is characterized in that: The bottom plate 1 is provided with a column 9, and a bearing 10 is provided on the column 9, and the drying bin 2 is provided with a gear 11, a discharge port 12, and a feed port 13, and in the drying bin 2 A stirring plate 14 is arranged inside, and the stirring plate 14 is set to a spiral structure, and the stirring plate 14 is set to a spiral structure, which is convenient for stirring and rotating the seeds in the drying bin 2, and can also dry the dried seeds. The drying bin 2 is released to improve the working efficiency. The motor 3 and the blower 4 are all arranged on the base plate 1, and the driving wheel 15 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com