Sealing structure for vapor chamber

A vapor chamber and sealing technology, which is applied to lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of complex manufacturing process, easy damage and loss of internal vacuum state, and difficulty in maintaining for a long time, so as to achieve no solder pollution and conform to The effect of environmental appeal and simplification of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

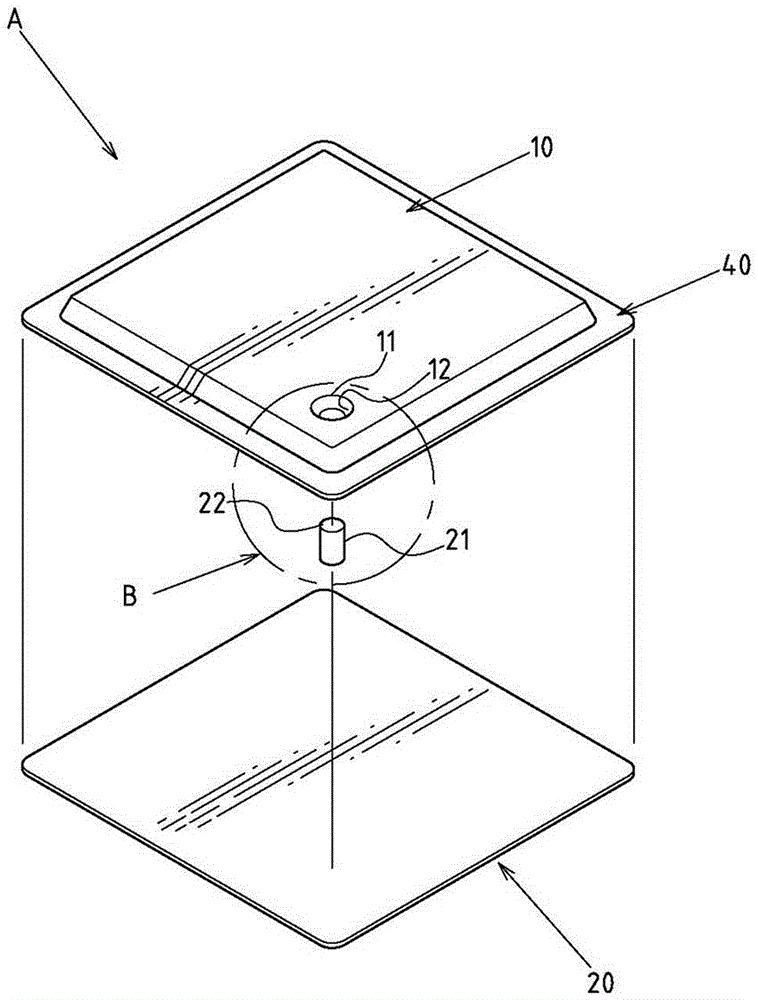

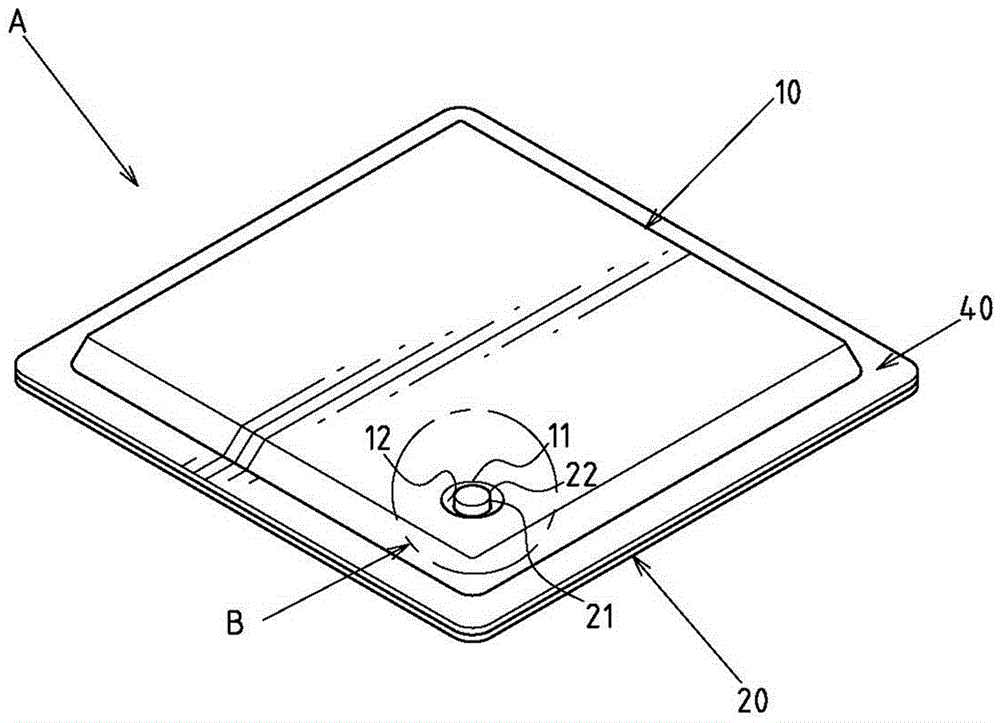

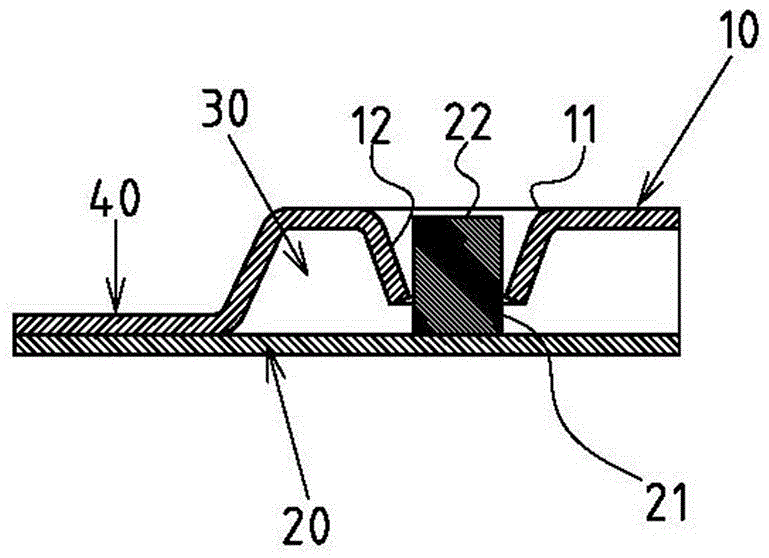

[0029] Example: see Figure 1~4 As shown, it is a preferred embodiment of the sealing structure of the vapor chamber of the present invention, but these embodiments are for illustration purposes only, and are not limited by this structure in the patent application;

[0030] The temperature chamber A includes an upper cover plate 10 and a lower cover plate 20 stacked together, a hollow chamber 30 is formed inside the upper cover plate 10 and the lower cover plate 20, and the upper cover plate 10 and the lower cover plate The periphery of the plate 20 is combined and fixed by a ring-shaped pressing edge 40, so that the hollow chamber 30 is in a closed state; the sealing structure B includes the following components:

[0031] One side faces the opening type operation hole 11, and the plate surface opened on the upper cover plate 10 is in the form of communicating with the hollow chamber 30 at a position close to the annular pressing edge 40, so as to vacuumize and inject liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com